Taiwan Machine Builders Aim for Higher-End Applications

Close Up: Taipei Plas

Major Taiwanese injection and blow molding and extrusion machinery OEM s plan to broaden the appeal of their brands by providing higher-end technology solutions at prices competitive with European or Japanese machines.

Major Taiwanese injection and blow molding and extrusion machinery OEM s plan to broaden the appeal of their brands by providing higher-end technology solutions at prices competitive with European or Japanese machines. That message emerged from a visit to Taiwan previewing some of the exhibits for the 12th Taipei International Plastics & Rubber Industry Show (Taipei Plas), coming Sept. 21-25 to Taipei, the Taiwanese capital (taipeiplas.com.tw).

Some of the latest developments from Taiwan include ventures into new molding styles, including what may be the first injection-compression system from that country; as well as advances in multi-part molding with new stack/tandem/family molding systems.

Newer machines boast higher speeds, tighter precision, or new capabilities to help molders enter new markets. New presses that apply electric servo drives to the hydraulic pumps for energy savings will also be shown—vertical machines included.

In extrusion, the first five-, seven-, and nine-layer blown film systems from Taiwan designed for medium throughputs are emerging, and a new shorter oscillating tower design has arrived. New flexographic or rotogravure printers and bag makers will also be displayed by builders of blown film lines.

SERVING UP SERVO

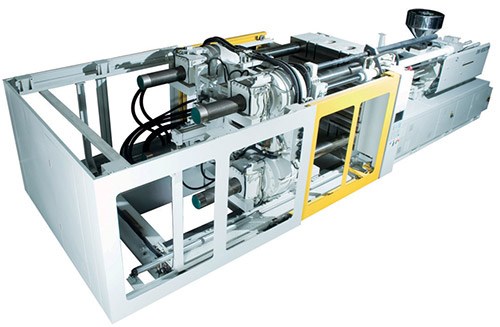

Fu Chun Shin Machinery Manufacture Co. Ltd., (FCS), the largest Taiwanese exporter of injection presses (fcs.com.tw), will introduce its HA-SV line featuring servomotor pump control of hydraulic

flow and pressure. The unit is based on FCS’s HT line of hydraulic machines designed for housewares and general-purpose products; however, the new line incorporates a number of modifications making it suitable for the U.S. market. And especially interesting to American molders is the new appointment of Maruka USA Inc., Pine Brook, N.J. (marukausa.com), as FCS’s sales agent for North America. Maruka is already known here as the distributor of all-electric machines from Toyo Machinery & Metal of Japan. The new arrangement with FCS gives it a hydraulic line as well.

FCS will offer the HA series in two versions: the HA standard line and the HA-SV servo system, both encompassing 11 models from 33 to 572 U.S. tons. The HA-SV version uses a Japanese (Daikin) servomotor to drive the pump system, while the standard HA version employs an electric variable-frequency motor to drive a variable-displacement pump.

The HA-SV series uses a new closed-loop control system that reportedly delivers faster machine response and shorter cycle times. Its servo-driven pump is said to consume 40% less power than a variable-displacement pump while holding part weight within ±0.4-0.7%. The new injection carriage structure features a guide plate that prevents deflection of the barrel. Maruka and FCS made the global debut of the 165-ton model HA165SV at NPE2012 in Orlando, Fla., last month.

At Taipei Plas, FCS will showcase production of a thick-walled, 130-g acrylic part using its new Hungry Feeder pellet feed-control system. The feeder and a new screw designed for this starve-feeding type of approach are said to minimize silver streaks, voids, sinks, bubbles, and black specks. FCS is showing the system on an HT-SV model together with new Vent Feeding Tube Technology, designed to reduce drying time for materials like PMMA.

Meanwhile, Jon Wai (represented in North America by Industrias Plasticas Maximo in Mexico, maximo.com.mx) redesigned its Thinwall (TW) machine line as its new SLIM series with servo-driven

hydraulic pumps. It will show the new presses with stack and family molds, the former being relatively new to Asian markets. Jon Wai (jonwai.com) says the new line can handle 20% higher pressures up to 170 bar (hydraulic) vs. 140 bar for a similar-sized TW model. Max. injection speed is upgraded to 800 mm/sec from 600 mm/sec previously. The series features Taiwan-built servomotors that are reportedly more powerful than those on comparable Japanese machines yet lower in cost. Jon Wai says its offerings allow mid-sized users with smaller volumes to get involved with higher-end technologies like stack and

family tooling or in-mold labeling.

The new series currently includes 220- and 280-ton models, though it will range from 150 to 480 tons. At Taipei Plas, the 220-tonner will run a 2+2 margarine tub and lid in a stack mold from Nypro of Clinton, Mass., with a cycle time of 2.8 sec. At NPE2012 in Orlando, Jon Wai showed the 280-ton SLIM model

with a 1+1 ice-cream tub and lid family mold and IML robot running at a 3.8-sec cycle.

Lien Yu Machinery Co. (ly-inj.com.tw) offers its new hybrid SV toggle series with a Taiwan-built servomotor and gear pump that are said to perform comparably to European brands at a cost less than

European and Japanese models. The SV line will span 75 to 2300 tons.

Multiplas (multiplas.com.tw), represented here by New Pacific Machinery, Trenton, Tenn., (newpacific@prodigy.net) is expanding in vertical, all-electric machines, adding a new 90-ton model to the existing 55-tonner in the V3E toggle line. Users can select horizontal or vertical injection and rotary-table options. The company is also rolling out the EMH050T, a 50-ton all-electric horizontal press with 570 mm daylight and up to 300 mm/sec injection.

TWO-PLATEN PROGRESS

Jon Wai will demonstrate a new area of competence at Taipei Plas—injection-compression molding combined with a rapid heat/cool (RHCM) mold. These capabilities will be demonstrated in running a 32-in. ABS television cover on a new 850-ton two-platen model—the part usually needs a 1300-ton press. Conformal heating/cooling channels in the tool allow for rapid

cooling of the part and a high-gloss surface.

Jon Wai demonstrated tandem molding at last month’s ChinaPlas show, producing 32-in. ABS television covers in a 1+1 tool on a 1200-ton JW-1200TP press. Although the 442-g front cover has a 35-sec cycle, and the 1371-g back cover requires 55 sec, overlapping the cycles with a tandem mold reduces overall cycle time to produce a front/back set in 65 sec. At Taipei Plas, Jon Wai hopes to trim the weight of the back cover to 900 g and expects to further shorten the overall cycle. Jon Wai says parts having up to a 30% difference in weight can be molded using a tandem or family mold approach, while reducing overall costs up to 40%.

Jon Wai is rolling out two-color (TC) injection presses with wider platens. A new 250-ton, two-color 250 TCW press at Taipei Plas will feature a platen measuring 1205 x 760 mm (H x V), which is wider than the standard TC model. The new unit will produce 10-in. H-P tablet covers from ABS and TPU on a 1+1 mold.

FCS added a new 850-tonner to its two-platen LM series, filling in a range spanning 650 to 3700 tons. The new model will be demonstrated with FCS’s gas-assist system to produce a 5.5-lb child’s car seat.

FCS also has developed a 1420-ton press in its HB-R line for multi-component applications. A larger

2000-ton version is being developed.

Lien Yu will unveil its new H-series of two-platen machines featuring servo-driven hydraulics. The series ranges from 1100 to 2300 tons and features a new servomotor design.

BLOWN FILM, BAGS & BOTTLES

Queens Machinery (queens.com.tw), a producer of blown film lines and printing and bagmaking machines, will show several new offerings at Taipei Plas. Queens will unveil new multi-layer blown film capability in production of 40-50 micron, five-layer structures featuring nylon barrier layers. The coextruded structure replaces lamination, and the barrier film has a ready use for meats or seafood.

Queens says that seven-layer and nine-layer systems for hard-to-combine materials are in development. Queens will also unveil a shorter oscillating film tower for use in factories with restricted vertical space. The tower is 600 mm shorter than conventional sizes, and is typically matched with the company’s redesigned

chilled-air system, which provides 68-77 F air for higher throughputs.

At Taipei Plas, Queens will demonstrate its new Meta-Q high-speed extruder, which processes 1100 to 1320 lb/hr and is designed as the primary substrate extruder in three-layer coextrusions. Screw and barrel

are designed for quicker changeovers.

Queens also has a new auto thickness control with a contact sensor on one of the film rollers. The company will roll out its FDW Jumbo-Type winder, designed to run three-layer structures 2.5 meters wide

at 100 m/min, as well as a new machine for small t-shirt bags.

Hemingstone Machinery (hemingstone.com), will show two new developments at Taipei Plas. It will display its first eight-color, central-impression flexographic printer, which will use water-based inks. Eight-color technology is well known worldwide, but the company believes the price point of a Taiwan-built machine (50-60% lower than other sources) can find buyers.

Hemingstone will also debut its H1100TR high-speed, fully automatic, coreless bag maker. It features a special knife and cutter design that can produce four rolls of 50 t-shirt bags a minute (200 punches/min).

Fong Kee International Machinery (fki.com, represented by Hollo Plastics Equipment Inc., Northfield, Ohio) will show off new extrusion and blow molding systems. In extrusion, the company has a new screw and controls for a sheet line producing 350 meters/min.

In blow molding, Fong Kee will introduce a smaller, high throughput, multihead machine based on its HBA continuous-extrusion series. The new model is designed to mold shampoo bottles under 1.5 liter. There’s also a new control system that allows for remote machine control through a secure internet link.

Related Content

Electric Injection Molding Machine Line Expands

Boy will debut three new models in its Electric series of machines, which feature a redesigned and more compact drive and inverter technology.

Read MoreArburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.

Read MoreCoinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.

Read MoreSecondary Injection Unit Provides Primary Benefits for Molder

Core Technology Molding turned to Mold-Masters E-Multi auxiliary injection unit to help it win a job and dramatically change its process.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More