The Right Way & The Wrong Way To Add Materials Conveying Capacity

Whether you're expanding your current plant or consolidating operations and moving equipment from one location to another, you will need to make sure that your material-handling system delivers the productivity you expect.

Whether you're expanding your current plant or consolidating operations and moving equipment from one location to another, you will need to make sure that your material-handling system delivers the productivity you expect. It doesn't do you any good to install an extruder sized for 2000 lb/hr when your pellet-conveying system can deliver only 1300 lb/hr.

You might be tempted to simply hitch more powerful pumps to your vacuum-conveying tubes. But it's not that simple. Pumps have to match the diameter of the conveying tube, or else the material will move too fast or not fast enough. There's also an optimum distance that pellets or regrind flake can be conveyed without frictional damage or lost efficiency. And there's an optimum number of hoppers or bins that can be loaded for a given size conveying system so that no machines run out of material.

Not too fast

If the vacuum pump is too big for the pipe, the pellets can travel too fast. The result is undesirable angel hair, fines, and streamers—perhaps enough to clog tubing elbows or hoppers. An optimally designed system picks up pellets from gaylords or silos at an initial speed of about 4000 ft/min, which accelerates to about 5000 ft/min as they travel throughout the system. If the pump is over-sized, material may be blasted along at up to 7000-8000 ft/min, which degrades the resin.

How much the material degrades at such high speeds depends on its coefficient of friction (COF). Softer resins with a higher COF, like EVAs and elastomers, tend to abrade easily in conveying tubes and elbows, producing a lot of angel hair and fines. Harder resins with lower COF, like PET or LDPE, produce dust on impact when they hit elbows at excessive speeds.

Replacing conveying tubing to match a larger pump is a lot of trouble and expense that you would probably rather avoid. In small systems, it may not be necessary. You can upgrade from a 3-hp pump to a 5-hp without difficulty because both work efficiently with a 2-in. OD conveying tube. But pumps of 7.5 hp and higher are efficient with only one tubing diameter (see Fig. 1). Above 7.5 hp, a rule of thumb is that increasing pump capacity by one typical size increment requires 0.5-in. larger diameter for conveying tubes. For example, a 7.5-hp pump matches a 2.5-in. tube; a 10-hp pump goes with a 3-in. tube; and so on.

If you try connecting a 10-hp pump to a 2-in. conveying line and don't slow the pump down, that will not only degrade your material quality, but it creates backpressure from forcing air into a smaller-diameter opening. That backpressure makes the motor run hot, which reduces the life of the pump, sometimes from years to mere months.

Not too far

There's also a limit to the distance that one pump can pull pellets through a conveying tube without degrading them. We usually limit this distance to about 300 ft before recommending an intermediate resin storage bin and another pump.

Resin type affects the intervals at which pumps are located and the distances material should travel in an ideal conveying-tube layout. But your plant's conveying layout should be resin-neutral because you can't always predict what materials you will be using in the future. Distances between pumps are also affected by the height of the conveying system, the configuration, number of elbows, the number of load and unload points, and even the kind of hoppers used on processing machines.

Continuous loss-in-weight gravimetric hoppers put more demand on the loading system. The gravimetric hopper must be filled by a specific amount—and only when it calls for it. That means you have to build in some conveying overcapacity to compensate.

The sizes of the hoppers and the conveying system must also be properly balanced. The system loads only one hopper at a time. It must be able to fill each one before any of them runs dry.

Building for expansion

In the long run, it's far less expensive to design a system from the beginning with future growth in mind. That means you will have to install a bigger pump and tube diameter than you need at first in order to have additional capacity later on. The cost of installing a 4-in. tube is not much more than for installing a 2-in. tube, and it will save you a lot later when it's time to expand.

A conveying system should always be designed with as few elbows as possible. Fortunately, it is often possible to reconfigure an existing system to remove elbows in order to make expansion easier. Those elbows that cannot be removed can be enhanced to handle higher conveying throughputs without degrading the material by replacing them with special flow-lined or spiral-groove tubing or products like the HammerTek "Smart Elbow" from HammerTek Corp., Landisville, Pa.

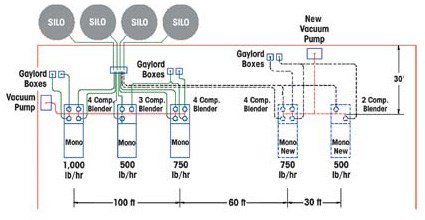

If your system was not designed with expansion in mind, it may be better to add another complete system to accommodate the expansion, rather than attempt to "stretch" the existing system. Adding a separate conveying system can be the only practical answer when the new group of machines has different material-handling components from those on the existing machines.

Even a series of separate systems can be optimized. Pumps can be sized to provide some back-up or redundant pump capacity—enough to keep two conveying lines running for a short while on one pump, if the need arises. A large seven- or eight-layer coextrusion line might also be designed with materials handling broken up into two or more separate systems to prevent resin contamination and to provide redundant pump capacity.

—Edited by Jan H. Schut

Stephen Buckley is v.p. of project engineering and marketing, and Michael Baker is a project engineer, at Process Control Corp. in Atlanta.

Related Content

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More