Things Are Adding Up Nicely For Charter NEX Films

Since Charter Films merged with NEX Performance Films about 18 months ago, the combined operation has melded the best capabilities of each company into a single business churning out a wide scope of blown films.

In business, the adage goes, one plus one doesn’t always equal two. You typically hear

something like this when one company acquires another and the combined entity’s performance winds up being less than what the individual companies generated on their own.

But they’re either practicing some kind of new math at Charter NEX Films Inc., or at least not paying much attention to what’s taught in MBA School. For since Charter Films, headquartered in Milton, Wis., merged with NEX Performance Films, Turners Falls, Mass., about 18 months ago, the combined operation has melded the best capabilities of each company into a single business churning out a wide scope of monolayer, coextruded, and specialty blown film products exceeding 200 million lb/yr from four plants for applications that include barrier films, shrink wrap, stand-up pouches, and flexible packaging.

Roughly 75% of Charter NEX’s films are used in food packaging, but the firm also serves a variety of other markets, including protective film to cover appliances during shipping; medical, tag and label film; pet food; and lawn and garden. Charter NEX employs 325 companywide.

The company does not release sales numbers, but business in 2013 grew above the market rate of 2-3%. Kathy Bolhous, the firm’s CEO, said she expects 2014 growth to be twice what was registered last year.

The Charter NEX story also throws cold water on another point of view frequently bandied about board rooms: that private-equity involvement is not a good thing for a company’s long-range plans. The film producer is backed by Milwaukee-based private-equity firm Mason Wells, which has several other packaging and converting companies in its portfolio. “Mason Wells takes a long-term perspective with respect to the companies it owns and strongly believes in investment as a key strategic element to growing those companies,” states Bolhous. That’s more than just talk, as the company’s growth plans make clear.

All Charter NEX plants operate on a 24/7/365 basis. Its largest plant (in Superior, Wis.) has 13 blown film lines. This plant runs a sizeable portion of the company’s output on single-, three-, five-, and seven-layer lines. In nearby Milton, Wis., which currently houses five film lines, Charter NEX is undergoing an expansion that will free up space for the addition of another five production lines.

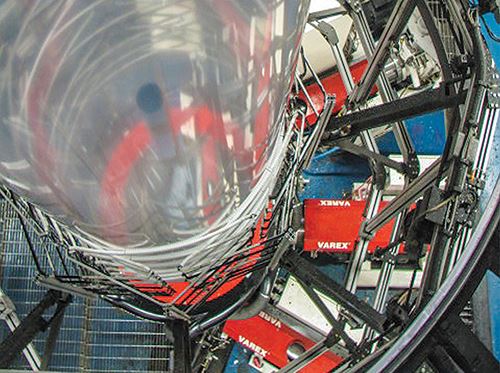

Rhinelander, Wis. is considered the processor’s barrier-film house; it currently has five lines that run up to nine layers. In Turners Falls, the processor has six lines with a seventh—a five-layer Varex II system from Windmoeller & Hoelscher, Lincoln, R.I., on the way. This is new technology introduced at the K 2013 show in Dusseldorf.

Bolhous explains that the Milton expansion is the first of several additions and upgrades the firm is planning in order to leverage its expertise in high-performance blown film manufacturing. She notes, “With our recent merger and the strong support of our ownership group, we believe that the time is right to expand and upgrade our Milton plant to support our strong growth. This expansion reinforces our commitment to provide our customers with unparalleled quality, service and technical support.”

Adds Chris Trapp, president and COO, “We believe in the superiority of W&H extrusion equipment. It has allowed our company to provide unsurpassed quality to our customers and has been a significant contributor to our successful growth. Two new state-of-the art W&H lines added in our Milton plant during the past year will provide increased flexibility and needed capacity while maintaining our ability to supply the highest quality, best performing, and most consistent film in the industry.”

Adds Bolhous, “You hear the word ‘synergies’ a lot, but that’s what’s come about since the two companies combined. As a company, we have a unified mission: to be leaders in blown film extrusion, to produce the industry’s highest-quality film, and to operate in a family-type atmosphere. But to execute that we have to share best practices between what had been two leaders in blown film. We think we’ve done that, and will continue to do so.

“The product-line strengths of each company complemented each other extremely well,” Bolhous continues. “For example, if you look at the history of the former NEX Films, one of their strengths for 20 years was in barrier films for cheese and meats. Charter had recently entered the barrier film market, but its primary focus was three-layer film. NEX also had strong expertise in processing specialty resins and difficult-to-run grades. Combined, we offer a wide variety of films to meet the requirements of our customers. There have been opportunities to learn from each other to improve the quality of all the products we make. A lot of our growth has come from being afforded new opportunities to grow with our existing customers, and I think that’s the result of this commitment.”

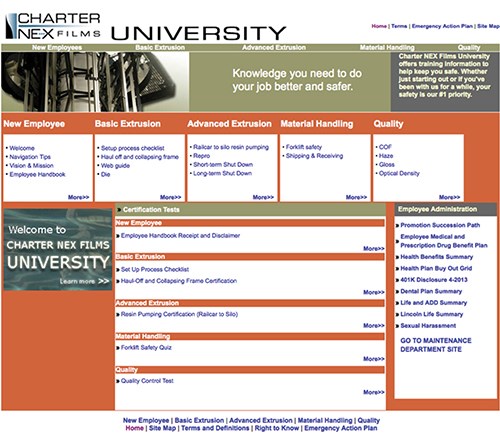

THE UNIVERSITY

What Charter brought to the union is an unwavering commitment to continuous process improvement that’s reflected in what it calls The Charter NEX University (CNU). CNU is the brainchild of Trapp, who co-founded Charter Films in 1998. Basically, CNU is a computer-based training program consisting of more than 100 modules on broadly categorized subjects such basic extrusion, advanced extrusion, material handling, and quality.

Within each of these broad categories are a series of video-based sessions. Under basic extrusion, for example, there are lessons on setting up, adjusting the bubble cage and size, and die function and maintenance. Advanced extrusion subjects include railcar-to-resin silo pumping, and short- and long-term shutdown. Subjects in the quality module include videos on gloss, haze, coefficient of friction, and optical density.

“All employees have access to CNU through our company intranet at any time,” Trapp explains. The lesson modules, which are continally updated, feature videos made by the employees themselves on their particular areas of expertise, filmed at the actual production lines. Throughout the training process, employees take online tests to determine their aptitude before they can apply what they’ve learned in production.

While employee participation in this program is not mandatory, Bolhous and Trapp are quick to point out that employee advancement in the company is predicated on it. This commitment to training has become a sales tool, says Brian Beuning, senior v.p. of sales and marketing. “When I make a presentation to a customer and talk about our training program and demonstrate how serious we are about it, it has a tremendous impact on the customer’s confidence in us as a film supplier.”

Charter NEX also has an unwavering commitment to technology. Companywide, its lines are equipped with automatic gauge control, gravimetric blending, oscillating hauloffs, and internal bubble cooling, all of which are regulated on the lines in real time. It runs bubbles up to 47 in. OD and up to 108 in. wide. Film thicknesses range from 0.5 to 12 mil.

Multi-component gravimetric blenders on all extruders accurately meter additions within ±0.05%. All additives are dosed on a ppm basis, allowing better control and consistency of film appearance and performance—clarity, opacity, COF, etc.

BROAD PRODUCT LINE

Charter NEX runs the gamut of polyolefins, as well as Surlyn (DuPont’s ionomer), nylon, and EVOH, among other materials. The firm breaks down its product offerings into several broad categories:

•Monolayer: These are generally are run on dedicated lines to minimize changeovers and startup waste. These films target commodity applications like lightweight or frozen foods, wrapped confectionery, coffee, and medical and industrial pouches.

•Multilayer: Charter NEX’s coextruded films are not the result of material blends, so each resin delivers the maximum in properties. Applications include peelable lidding, wipes, nuts, pet food, medical-device packaging, and stand-up pouches.

•Barrier films: The firm offers a complete line of custom barrier films for a variety of packaging technologies including metallization, nitrogen flush, and vacuum packaging. Barrier films of up to nine layers are engineered for meat snacks, cheese, liquid packaging, cookies, nuts, pet food, and more.

•Specialty films: Charter NEX developed and patented a controlled-COF technology (CCT). As Trapp explains it, CCT allows for more control over COF, which makes it easier to maintain a medium-slip range during conversion. This results in less transfer of slip to PET, oriented PP, and nylon top webs; less slip buildup on equipment; and less slip scalping by adhesives and ink. CCT also reportedly increases stability at higher temperatures from the outside of the roll to the core. CCT films are available in single- and multi-layer structures and have been used for applications in lawn and garden, coffee, cheese, snacks, and pet care.

The processor also has a range of what it calls SuperC films, designed for general-purpose packaging in either monolayer or coex structures:

•SuperC–Economy: For applications that require moderate strength, enhanced seal performance and a competitive price. Applications include candy, confections, snack food, and coffee.

•SuperC–Optics. These provide added softness, superior sealing, and optimal haze and gloss for shelf appeal. These are suited to low-temperature flexible packaging that needs extra sealant flow and caulking. Applications include food packaging, window packaging, candy and confections, and other products that require enhanced shelf appeal.

•SuperC–Modulus. They offer extra stiffness, high-speed production, strength, stretch resistance, enhanced seal performance, and balanced haze and gloss. Their stiffness allows for possible downgauging in unsupported films and can add stiffness to laminated structures. Applications include paper/product overwrap, stand-up pouches, and soft goods.

•SuperC–Strength. These provide toughness while maintaining outstanding gloss, haze, and sealant properties. They are formulated to be freezer-tough and resistant to stress cracking and impact. Applications include frozen foods, boilable products, dry goods, pouches, and coffee.

ANALYTICAL TESTING

Charter NEX supports all of these manufacturing capabilities with a fully instrumented lab at each location, where it has the ability to develop and test film constructions in an effort to give its film converter and packaging customers a competitive edge. The firm tests both physical and chemical compositions, explains Eric Smith, general manager of the Superior plant.

Laboratory tools include heat sealers, hot-tack testers, haze/gloss meters, thickness gauges, offline gauge profilers, digital COF testers, FT-IR spectrometers, DSC, and instruments to test for tear strength and dart impact.

States Smith, “Knowing which film structures are used for specific applications is extremely valuable. This is particularly important when entering and exploring new markets and opportunities. Establishing correlative testing with a supplier of polyethylene film materials provides a further advantage. Films are tested in advance to ensure essential characteristics before becoming part of a critical lamination.”

Related Content

Materials Suppliers Team on PFAS-Free Solutions

Baerlocher PFAS-fee process aid passes muster in resin manufacturer’s testing on production-sized blown film line.

Read MoreFlexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreNovel Air Ring Solves Gauge Variations for Film Processor

Crayex installs Addex gauge-controlling air ring built for rotating/oscillating dies on a problematic line and notices dramatic improvement in thickness variations.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More