To Improve Feeder Performance, Start by Understanding Three Key Components

These are the screw trough, agitator, and the screw itself. It’s crucial to understand the different types and the advantages/disadvantages of each.

Many loss-in-weight feeders incorporate a screw as the feed device due to its wide feed-range capability. Each selected feed device has a range of available screws with different diameters and pitches. Each feeder supplier provides a range of models capable of providing feed rates over the spectrum of normal applications.

The feed device is comprised of several components. Those discussed here are shown in the accompanying image.

SCREW-TROUGH AGITATION

The screw trough is a critical component of a screw feeder. It converges dimensionally from the inlet, attached to the extension hopper, and into the screw. It transitions the mass of dry ingredient contained in the feeder from the larger-dimension extension hopper into the smaller-dimension screw. Most dry ingredients (powders, granules, pellets, fibers, and flakes) do not flow reliably through converging transitions. There is friction between the particles and an interlocking tendency that restricts or stops the flow. When the flow stops it is called a “bridge.”

All dry ingredients have a minimum bridging dimension. Flow stops and a bridge forms at this cross-section dimension. The reducing cross-section dimensions in the screw trough eventually reach the bridging dimension. An agitation device is incorporated in the screw trough in order to prevent the bridge from forming.

There are two common types of agitation devices:

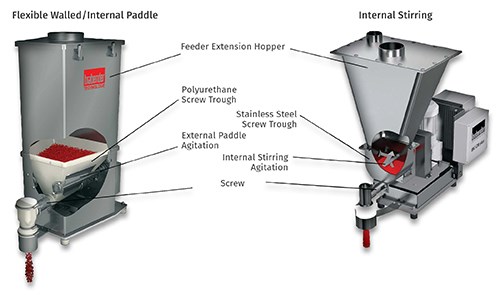

Flexible walled/External paddle: The screw trough is constructed of a flexible material, normally polyurethane, in a wedge shape on two sides and near vertical on the other two sides. Movable metal paddles contact the two wedged-shaped sides and “massage” them, pushing the sides in and out continuously. This movement causes an unstable support for the dry ingredient particles. A restriction movement followed by a void movement causes any bridges that are starting to form to collapse. Gravity acts on the particles to move them down and eventually into the screw.

Internal stirring: The screw trough is constructed of metal, normally stainless steel, and is curved in a constant radius to accommodate the close movement of rotating, agitating blades. The agitator blades move through the dry particles on each side of the screw, which is positioned directly below the agitator blades. Movement is down into the screw on one side of the screw trough and up on the other side. This blade movement prevents bridging in the screw trough.

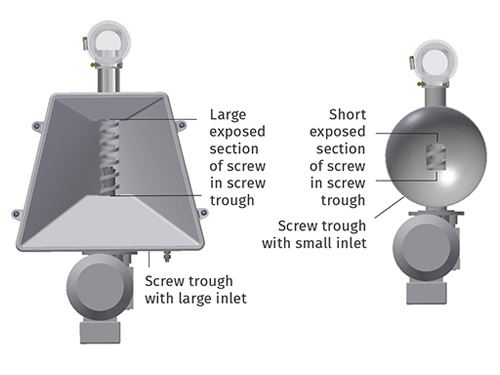

The shape of the screw trough is critical. A loss-in-weight feeder’s main purpose is to feed the ingredient accurately at the desired setpoint. The weight-feedback control requires that each screw flight be filled with the same weight of ingredient. Repeatable-weight filling of each screw flight is achieved by a properly designed agitation device (flexible-walled with external-paddle massage or with internal stirring). Also, there must be sufficient screw flights exposed openly in the bottom of the screw trough so that complete and repeatable filling occurs before the ingredient is enclosed in the screw tube. The best screw-trough shape is a wedge, rather than a spherical or conical shape at the bottom of the screw trough, in order to expose the required length of screw to fill properly (see image opposite).

Lately, the flexible-walled/external-paddle-massaged screw trough, available from several suppliers, has drawn more interest. One important reason for this is that the movement of the flexing screw trough directly contacts and massages the ingredient in the screw trough on both sides of the wedge surfaces, from the top inlet to the top of the screw.

Since the stirring agitator has a circular motion, there are two dead zones (no agitation) at the top of the screw trough. The screw trough is sized to reduce the volume of the dead zone. As a result, the flexible-walled/external-paddle-massaged screw trough typically has a larger volume and inlet dimension than the internal-stirring screw trough. Since the extension hopper is mounted directly above the screw trough, the bottom dimension of the extension hopper is typically the same as the inlet to the screw trough.

Loss-in-weight feeder extension hoppers are commonly sized (rule of thumb) to contain 4 minutes of storage at the maximum feed rate/minimum bulk density of the ingredient. The extension hopper often can be supplied with vertical sides, which provides floorspace advantages over conical extension hoppers. Also, there is no requirement for additional stirring agitation in the extension hopper, since the sides are vertical (no converging).

Generally, a screw feed device with flexible-walled/external-paddle-massaged screw trough is a first choice for loss-in-weight feeders. However, there are situations where the stirring agitator is required:

• Cohesive ingredients: These form a solid mass when exposed to compression. Some are so sensitive that the force of gravity acting on their own head mass can cause them to solidify. These ingredients are difficult, sometimes impossible, to feed reliably without excessive maintenance. Testing is highly recommended at feeder manufacturers, who offer several types of feed devices. Stirring agitators may have the best chance of success in such cases.

• Ingredient temperature: Polyurethane becomes too soft at ingredient temperatures above 50 C (122 F), requiring a metal screw trough.

SCREW SELECTION

The screw is the component of the feeder that provides the feeding. The agitation only ensures that the screw flights fill uniformly. Screws are selected to achieve maximum and minimum feed rates. The screw diameter and pitch are sized to achieve the feed rate at an optimal screw rotational speed. At too low a screw speed the “pulsing flow” may cause an undesired variation in the final product. Too high a screw speed may cause incomplete filling of the screw.

There are three common screw types, shown in the accompanying image:

• Spiral screw: The single-spiral screw is the most common selection. It is “open” for the ingredient to flow freely into the flights of the screw. It has a smaller surface area that helps reduce adhesion of the ingredient, which changes the screw volumetric geometry. Ingredients are transferred with low shear. On the negative side, aerated ingredients can easily flood past the screw flights.

• Blade screw: The single-blade screw offers more resistance to aerated ingredients, but because there is more surface area, sticky ingredients can adhere, reducing the volumetric geometry. Blade screws are often preferred for heavy powders with bulk densities of more than 80 lb/ft3.

• Twin concave screw: Twin concave screws can provide superior performance for poorly flowing powders. Twin concave screws are co-rotating, intermeshing, and self-wiping. The powder flows around the flights of both screws. The negative effects of some adhesive powders are reduced by the self-wiping of the two screws. Twin concave screws are solid and the screw flights have a low volume compared with spiral and blade screws. The shear on the powder is high, particularly in the screw tube. The screw tube is typically short to reduce negative effects of high shear.

Twin concave screws are ideally suited to powders with feed rates below 5 ft³/hr. The cross-section of the two screws is wider than an equivalent single screw, reducing the tendency to bridge in the transition from the screw trough into the screw. Also, screw speeds for twin concave screws can be higher than single screws for the same feed rate because of the larger inlet and low volume of the screw flight. Higher screw speeds reduce the negative effects of pulsation.

Reliable performance of loss-in-weight feeders begins with the selection of three critical components: The screw trough, the agitation, and the screw itself. It is necessary to understand the different types and the advantages/disadvantages of each. You’d be wise to witness testing the alternatives first-hand at the feeder manufacturer’s facility, using a sample of the ingredient to be fed.

Related Content

Gravimetric Feeder is Compact, Easy to Clean

Said to offer precise rate control for free-flowing pellets and granules.

Read MoreACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.

Read MoreProgram Provides Equipment Maintenance, Overhauls and Upgrades

NPE2024: Program aims to ensure equipment remains at peak performance levels throughout its life cycle.

Read MoreFeeders Now Furnished With Portable Touchscreen Controller

New portable controller maintains functionalities of previous controller while introducing significant enhancements.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More