To Produce Quality Extrusions, Get Control Over Melt Temperature

Temperature zone settings are often misunderstood and improperly adjusted. This often contributes to poor film quality and lower production.

One of the first items mentioned in any extrusion discussion is the melt temperature. This is the only temperature that is absolute. It does not refer to the temp of some steel that is away from the plastic melt flow. All other temperatures either help to produce it, or are determined by it. Is your melt temperature reading correctly? Are your zone temperatures set correctly? Is bad information better than no information? In extrusion, the objective is to produce one homogenous melt temperature at the tip of the screw. At that point, the melt has been sheared, heated, melted, and pumped. It is then forced through a screen pack, and its temperature is measured as soon as practical. Attempts to then cool this melt uniformly in an adapter, rotator, or die will be fruitless and result in multiple melt temperatures emerging from the die.

A flush-tipped melt thermocouple, or one that is integrated into a pressure gauge, will measure far more steel temperature than plastic. If you need proof, identify the temperature zone where your thermocouple is located. Take note of both the melt temperature and the temperature of the zone. Now raise the temperature of that zone by about 30° F (17° C) and wait until the zone temperature levels. If your melt temperature has remained the same, then your melt thermocouple is reading the plastic melt. If the melt temperature has increased substantially, then you are reading much of the steel surrounding the tip of your thermocouple. The amount of indicated melt temperature increase will give you an idea of how wrong your melt indication can be.

The plastic flow through an adapter tube is typically shaped like a parabola, with the hotter material flowing up the middle with cooler material surrounding it. Also keep in mind that plastic melt is a very sticky, viscous material that flows nothing like water, as many assume. The plastic particles touching the steel are not moving, and those near the steel are hardly moving. Therefore, most flow always goes up the center, where it finds less resistance. It is not flowing fast, like water from your hose. It does not mix well, as demonstrated by any multi-layer die that is able to merge multiple plastic materials inside a die without mixing them.

A thermocouple should protrude into the round flow cavity to about one-third of the cavity’s diameter to register an “average” temperature of the plastic flow. A 1/2-in.-long (13-mm) immersion tip with a 1/8-in. (3-mm) diam. probe is practical for all adapters. It will measure plastic with almost no effect from the steel surrounding it. Its small mass can react quickly enough to sense most temperature variations occurring from various causes. A 1/2-in.

immersion tip does not bend or break as easily as longer tips when any unmelted material from the cone-shaped plastic mass (after the breaker plate) gets shoved down the adapter bore during a too-cold start-up.

Note that some thermocouple tips can bend and still work. If you unscrew one and find thread marks along its immersion tip (20 threads/in.), that’s a sign it was bent. Others can break off. This has caused many people to rely on flush-tipped thermocouples. Should a 1/8-in. diam. tip break off, it will flow to the die, where it may not pass through the final die lip. (I have had them pass through a 0.050-in. (1.3-mm) blown film die gap and nobody noticed it.) If it does get stuck in the die gap, you’ll be able to tell when a strong weld line appears in the bubble. You may have to remove the die center cap to extract it.

BARREL ZONE TEMPERATURES

An extruder screw design, running at its normal production rate, will dominate your resulting barrel zone temps and will control the melt temperature on any resin. Thankfully, screw designs have improved substantially over the years, beginning in the 1960s with Bruce Maddock’s still famous “Maddock mixer.” Barrel-zone cooling systems that relied on water used to be common on blown film lines, but have all but disappeared in favor of simpler, less effective air cooling as screw designs have improved dramatically. Barrel heat is commonly needed only to get the process running. Then, shearing of the resin particles under high pressures takes over the job of melting. Barrel cooling may help to control temperatures, especially at maximum outputs, but the screw will dominate the process.

The first barrel zone is still typically kept at lower tempera- tures on smooth-bore extruders. This can help resin feeding and reduce heating of the feed section, which could lead to material sticking onto hot screw flights below the hopper, cutting off resin flow to the screw. If there is no water cooling in the cast feed section, then barrel heat transfers back through it into the thrust bearing, oil, and gearbox. This is not a good situation.

The last barrel zone is typically overriding its temperature setting, even with continuous air cooling as we attempt to reduce melt temperature. Obviously, the screw design is dominating this zone. Also, mixing devices are commonly located there. Almost any mixer will shear the resin, which generates additional heat.

Zones two and three can be used to assist the screw in feeding or melting, but only the screw can melt 100% of all the plastic particles into one homogenous temperature. Remember that plastic is a very good insulator and a very poor heat conductor. It will not transfer its heat or cold easily to arrive at a uniform temperature. If you want to discover what the screw design is doing, on its own, wait until all temperatures have settled in a production situation. Record all temperatures. Then shut off all heating and cooling to the barrel zones and observe the zone temps and the melt temps as they settle at new temperatures. Then, turn on only the barrel cooling and observe the same.

Your barrel-temperature control is limited. Perhaps you can raise zone two and try to assist the screw with melting. If so, you want to see the extruder drive amps and/or melt temperature decline. Almost anything you want to try is not dangerous if you monitor extruder drive amps and pressure...unless your operator sets a barrel-zone temperature below a safe operating temperature in an attempt to reduce barrel temperatures and thereby melt temperature. Then, if the line stops or drools for any reason, that zone will eventually go to that low set temperature. Upon restarting, high amps and pressures can occur that could blow a screen or break a screw. Some operators have a hard time understanding this.

OTHER DOWNSTREAM ZONES

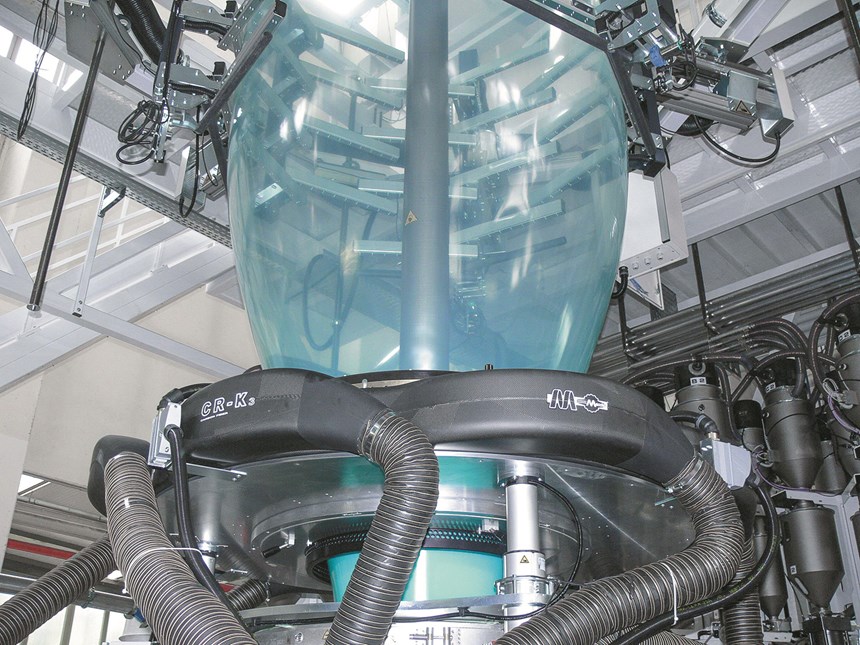

Once a melt with a homogenous and known temperature is established, it then needs to be conveyed all the way to the die lip. In blown film, the air-ring components of both conventional and IBC systems are expensively designed to cool the bubble uniformly around its circumference. The melt temperature emerging from the die will largely determine how quickly the resin cools—and at what thickness. If this emerging melt consists of a variety of temperatures, forget about producing a consistent gauge profile. You will probably experience gauge bands, bubble instability, system instability, and all of its associated problems.

Locate zone-control thermocouple tips 1/4 in. (7 mm) away from the actual resin flow cavity, because the only temperature to be concerned about is the steel that is touching the resin. Modern temperature controls have no problem controlling steadily within about 1° F.

Therefore, all downstream flow cavities theoretically want to be at melt temperature, if it is known correctly. This is almost impossible to accomplish, depending on thermocouple locations and likely presence of cooler, unheated spots on rotators, blocks, die ports, etc. Also, it is human nature for operators to reduce these temps “in order to cool the melt” and thus “run faster.” But never set these downstream temps more than 25° F (14° C) below melt temperature. This usually results in a consistent melt temperature from the die and reduced gauge bands.

With or without a known melt tempera- ture, it is not uncommon to see an adapter zone being cooled continuously in room air, but its temperature controller never calls for heat, or it heats less than 10% of the time. In such situations, the hot melt inside the adapter is obviously heating this adapter zone and thereby cooling a part of the melt flow. Unless this cooler melt gets sheared and reheated or thoroughly mixed in the die spirals, it will emerge as cooler streaks on the bubble creating gauge bands and instability. One common way operators correct for such errors is to reduce output, run slower, and lose profits without ever correcting the actual cause.

ABOUT THE AUTHOR: John R. Myers has been an engineer in extrusion for more than 50 years and has worked as an independent consultant to the global blown film industry since 1974. Myers has been instrumental in establishing seven blown film operations but mostly works with existing plants on training, design, or improvements to processes and technology. Contact: 513-671-0076; johnrmyersco@aol.com.

Related Content

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

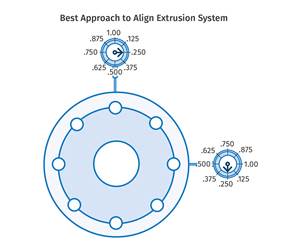

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More