Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

The design, efficiency and durability of temperature-control units (TCUs) have improved process control across the plastics industry since they were first used in the 1960s. Because TCUs are generally so reliable and versatile, they often get moved around a lot and are connected to different water sources and a variety of molds and process equipment. Because of this transitory existence, the number-one troubleshooting concern for TCUs typically involves leakage.

Leaks generally occur as a result of one of the following conditions — loose fittings; worn pump seals or seal failures; and water quality problems.

The most obvious sign of a TCU leak is visible water, but by following a few key guidelines in installation and maintenance, you can avoid the failures that end up with water on your shop floor.

(Photos: Conair)

Eliminate loose fittings

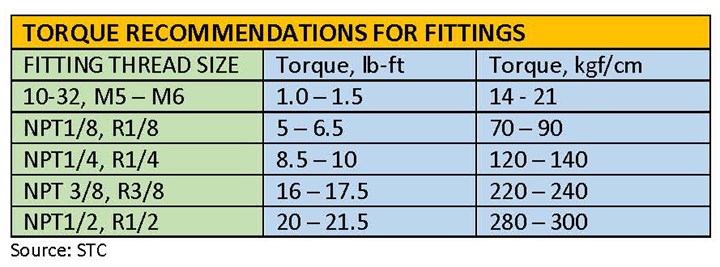

One of the most obvious sources of leaks is loose fittings. These may occur when manifolds, hoses or pipe fittings are initially assembled and connected to the TCU. Leaks can also develop over time as the TCU undergoes heating and cooling cycles. To make a leak-tight connection, it is always best to:

• Inspect both the male and female thread for any contamination or damage.

• Apply sealant to the male thread, using three wraps of Teflon (PTFE) tape, and then apply plumber’s liquid sealant starting at the second thread, so the first taped thread engages cleanly. (Note: for PVC threads, use only a liquid sealant, since the added bulk of PTFE tape or paste sealants can and will cause cracking.)

• Screw the male thread into the female thread until it’s hand-tight. Mark a line across both the male/female surfaces of the connection to indicate the initial seating position.

• Tighten the connection using an adjustable wrench (not a pipe wrench), using either TFFT (finger-tight plus 1.5 turns) or a torque wrench, and mark the final tightening position on the adjacent surface.

Minimizing Pump-Seal Failures and Leaks

Misaligned pump seals or improperly tightened set screws or gland bolts will lead to leakage, but there are more complex factors to consider as well. For instance, TCUs typically use one of three seal materials, depending on the application, fluids used and operating-temperature requirements

Nitrile rubber or Buna is the most economical seal. This synthetic rubber is intended for use in low-acidic and mild-alkaline environments (water pH of 6 to 8), and at low-to-moderate temperatures (80° to 200°F). It is also relatively easy to damage, so handle these seals carefully.

EPDM is a synthetic rubber with elastic properties superior to Buna, and a wider operating-temperature range (up to 250°F). They also can be easily damaged and can be incompatible with certain oils or acids.

Fluoroelastomers, such as Viton (manufactured by Chemours) are used to make higher-priced pump seals. These can operate under considerably higher pressures and they offer a longer lifespan, especially in more demanding environments.

At temperatures above 250°F, the circulating fluid is not as effective in cooling or lubricating the seal surface, so lower-temperature seal materials can be compromised. Similarly, the seal material must also be compatible with other coolants, such as glycol, or it will begin to break down. Improperly selected seal materials will also be subject to higher friction with other components, leading to premature failures and leakage.

In addition to alignment or tightening issues, pump-seal failures can be caused by the material used for the seal itself.

Operating errors only make the problem worse. If a pump is allowed to run dry, even for just a few seconds, frictional heat can cause irreversible damage in the form of cracks and blistering, so that leaks occur when fluid is returned to the system. Abruptly shutting down a TCU pump running fluid at high temperatures is also not a good practice because it traps hot fluid in the pump, which could damage the seals. A better approach is to reduce the fluid temperature to at least 125°F before shutting down. This not only cools the seals, prolonging their life, but also prevents the risk of scalding accidents if personnel see that the system is off and attempt to disconnect it and move it to another location.

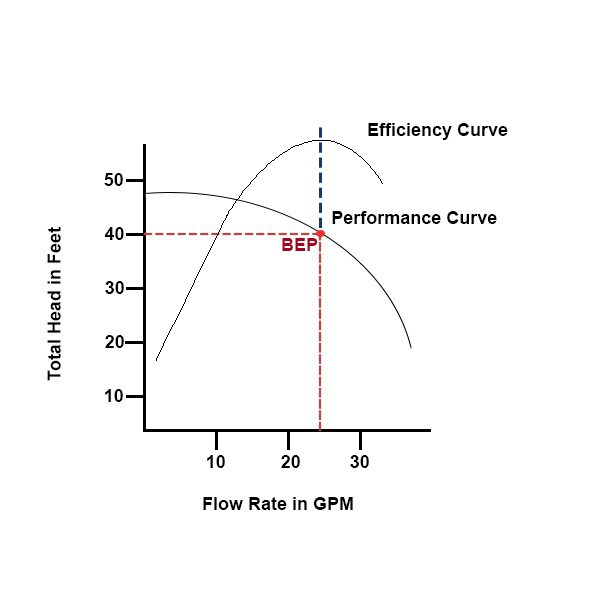

Excessive vibration can also lead to seal damage and leaks. Pumps have an operational sweet spot referred to as their “best efficiency point” (BEP). BEP is the balance of fluid flow and pressure that yields the highest efficiency without inducing too much vibration. Increasing pressure can shorten seal life, but using a lower pressure with a higher flow rate can increase motor rpms, raising temperatures and potentially damaging the seal.

Determining the best efficiency point (BEP) for your pump, or its operational sweet spot, will yield the most efficient operation with minimized vibration.

Excessive vibration can also lead to axial and radial movement of the pump shaft, damaging the shaft seals. A certain amount of coolant is needed to lubricate the mechanical seal faces. Shaft misalignment can mean there is too much fluid at the seal interface so that some leaks out. Too little fluid, however, results in excessive friction, rapid seal wear, and eventual leakage. Bearing wear is another problem, since it allows for increased shaft movement, vibration and seal deterioration. Contamination in the seal support system or the pump itself also contributes to wear and potential leakage.

If it is suspected that TCU leakage is due to seal damage or failure, maintenance personnel should check the suction pressure and discharge-pressure gauges to determine whether the pump is operating correctly. They should also check the to-process and from-process water temperatures and listen to the sound of the pump. Each of these steps can reveal whether there are additional problems with the pump seal and bearings while also helping confirm the location and cause of the failure.

Corrosion and Poor Water Quality

Water is the primary — and sometimes the only — element in the coolant flow, and whenever water and metal are present, corrosion or rust can become a major problem. Once it begins, corrosion creates a rough surface within pipes and fittings, causing a gradual build-up of impurities and a thinning of the walls of the flow path, making it vulnerable to leaks or breakage, not only in the TCU, but throughout the cooling circuit.

Consequently, the characteristics and quality of incoming fill water are very important (see chart). There are three major causes of corrosion:

pH: The water’s acidity ranges from 0, which is the most acidic, to 14, the most alkaline, while a pH of 7 represents a neutral pH. If the pH is 8 or higher (more alkaline and less acidic), a film of copper oxide will form on the inside of copper pipes, slowing or minimizing any corrosion. However, if the pH is neutral or more acidic, this copper oxide barrier is dissolved, leaving the copper pipes vulnerable to accelerated corrosion.

Oxidation: The water that flows into the cooling circuit contains dissolved air, including 78% nitrogen and about 20% oxygen. Oxygen corrodes metal pipe surfaces through the process of oxidation, converting metal to oxides, and starting a chain reaction. First, the rust accumulates, causing a rough surface in the pipe that captures other impurities, resulting in a gradual buildup. Over time, that buildup traps additional impurities and grows. Eventually, it thins the pipe wall, creating the potential for pinhole leaks or cracks, especially if circuit pressure surges. The higher the water temperature, the faster oxidation occurs — hence, hot-water lines are always most vulnerable.

High flow rates. Higher flow can aggravate the problem, causing built-up rust and impurities to break off and wear down interior surfaces like elbows.

The buildup of scale inside pipes also affects TCU efficiency and performance: Just 0.01 in. of scale buildup can reduce heat-transfer efficiency by 10% and lead to premature pump-seal failures. If water-quality analysis shows that scale is a problem in supply water, a descaling system can be installed to remove the calcium deposits that cause the problem.

Dissolved air in process water will lead to oxidation within the pipe and rust buildup.

Overall water chemistry is very important, not only for optimum TCU and process temperature-control performance, but also for the health of other machinery that relies on the cooling system, including molds and molding machines. For that reason, processors should consider water-quality analysis and should strive to maintain water quality within these recommended guidelines.

Design Improvements

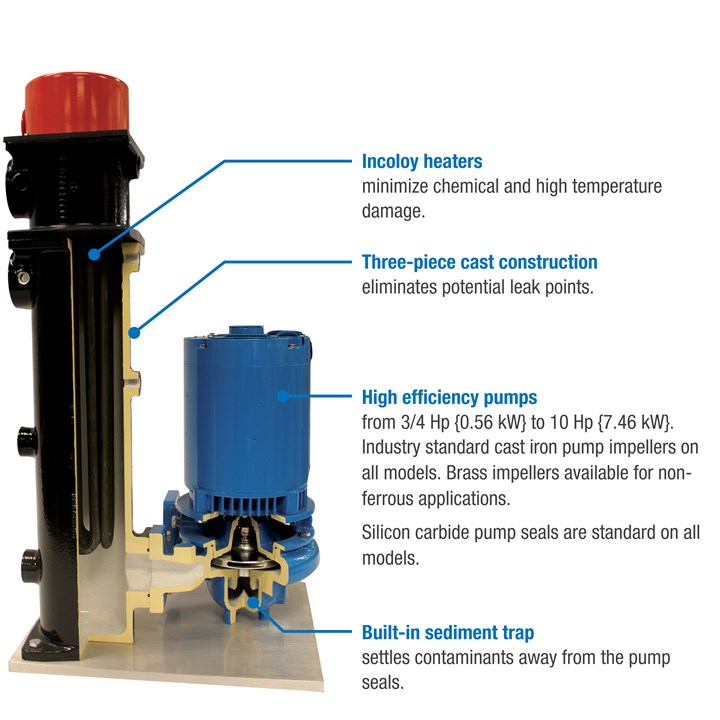

TCU manufacturers have worked steadily to improve TCU performance and eliminate the sources of troublesome leaks and other performance problems. For instance, a heavy cast pump volute with the heater and mixing tube combined into a single unit can minimize potential leakage. Conair has worked closely with its pump vendor to develop a unique pump design that aligns directly with the heater-tube and mixing-tube casting so there’s no need for threaded or soldered connections, which can be prone to leakage.

To minimize the maintenance problems (and puddles) associated with the operation of pressure-relief valves, Conair’s newest TCUs offer an adaptive pressure-relief valve, which communicates with the coolant valve to automatically open and relieve excess pressure. The adaptive pressure-relief function can be adjusted via the TCU control interface, which provides digital displays of system pressure, valve position and other variables.

Newer pump heater designs can eliminate potential leak points and achieve greater efficiencies.

TCU design will continue to evolve toward greater ease of use and minimum maintenance requirements. In the meantime, to ensure long-term leak-free performance, while minimizing temperature-control maintenance headaches, be sure to check your fittings and ensure that they are tight. Employ regular, smart preventive-maintenance procedures to avoid major equipment failures in the future and consult with your equipment supplier for help in selecting and sizing a TCU and the cooling valve for the application at hand.

ABOUT THE AUTHOR: Jim Fisher is the general manager for heat transfer at the Conair GroupConair, Cranberry Township, Pa., with more than 34 years of experience in the plastics industry. He holds a bachelor's degree in mechanical engineering from Bradley University and first worked in the industry as a manufacturer's representative, serving the tooling design, injection molding, blow molding and the extrusion markets.

Related Content

Temperature Control Unit (TCU) Modulates Heat Output in Real Time

Delta T Systems’ Smart series water TCU features “Vari-Heat” technology for greater precision and efficiency.

Read MoreRelaunched Chillers, Blenders, Dryers

NPE2024: New auxiliaries from AEC include chiller that meets new standards for refrigerants.

Read MorePackaged Chillers, Central Chillers, New Controller for TCUs

NPE2024: Sterling debuts broad range of products for temperature control.

Read MoreHigher Efficiency and Temperatures in TCUs

At Fakuma, Wittmann’s temperature control unit (TCU) displays featured a prototype Tempro capable of achieving 200°C (392°F) in process temperature and the application of EcoDrive motors.

Read MoreRead Next

Heating/Cooling: Temperature Control Offers Non-Ferrous Cast-Bronze Construction

For Conair’s Thermolator TCUs that use water as coolant there is now an optional non-ferrous construction for all wetted parts.

Read MoreTCU with Common Control Offers Smaller Footprint, Ease of Operation

Units sized at 3 hp and under also require 15% less floor space than earlier designs.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More