Worldwide Switch to New Gauging System Pays Off for Haartz

Leading supplier of sheet and roll stock for automotive applications reevaluated its thickness-measurement technology in 2012, and now has 15 scanners in place worldwide from one supplier.

Family owned and in business more than 100 years, Haartz Corp., Acton, Mass., is the world’s leading supplier of automotive topping fabrics and a leading producer of soft-trim car interior materials. Roll and sheet goods made by Haartz can be found in almost every automotive brand worldwide, especially in convertible tops.

In Acton, surface effects such as simulated leather are embossed into extruded PVC, TPO or other compounds to create formable and hand-wrap materials. These materials are used in door panels, seats, console lids, instrument panels, and more for automakers from Nissan to BMW. Some lines are set up to extrude material onto a thin layer of foam, giving the trim more cushion. Haartz also extrudes plastic between two layers of fabric.

In 2012, an effort to streamline production focused on the company’s web gauging and control systems. “Back then, our web scanners were made by two well-known manufacturers,” recalls John Gilbert, senior process engineer in Acton. “Our people wanted to find the best scanner brand for us as we began planning the upgrade of our extrusion lamination lines.”

Haartz typically runs at thicknesses ranging from 0.5 to 1.3 mm. Strict control of the extrusion process is critical to meeting Tier 1 supplier specs as well as IATF16949 Automotive Quality standards. Going outside standard deviation limits risks failing spec and wasting material. So, by employing just one brand of gauging system across the board, Haartz could enable all line operators to gain a better knowledge of the system selected and produce more consistent and efficient products.

“Because we run the lines on a 24/5 or 24/6 basis, our operators need to move from line to line so vacations, sick days, and shift changes can be well covered,” Gilbert said. “It was crucial to select a system they all could easily adapt to and that could fulfill all our requirements as we pushed our capability.”

KICKING ALL THE TIRES

The company wanted the best system for its future. “We talked with every major manufacturer out there,” Gilbert explains. “Our search included a parade of presentations and proposals, plus dozens of site visits over many months and several states.”

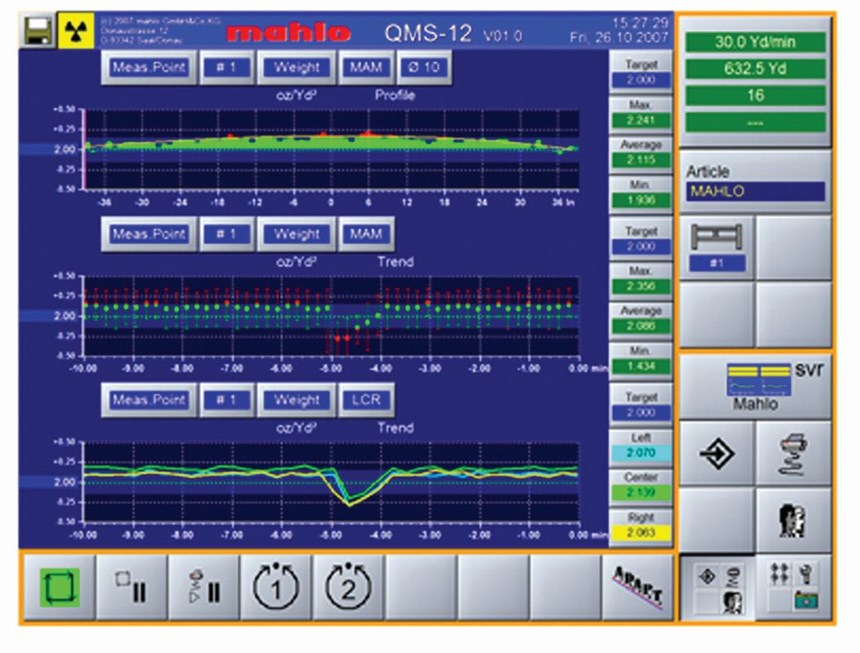

What they learned surprised everyone on the selection team. One brand not only fit all their needs, but Haartz found the differences between a system provided by Mahlo America, Spartanburg, S.C. (mahloamerica.com) those from all other vendors were “stunning.” The team’s first impression was that the machine “is built like a tank.” As a bonus, most Mahlo parts are easily sourced from aftermarket suppliers--even motors and circuit boards. “With our legacy scanners we were compelled to sign service contracts,” Gilbert admits. “After X number of years, the manufacturers stop supporting them. We were expected to buy new.”

Gilbert adds, “Mahlo said they still support scanners 25 and 30 years old. That moved them to our short list.” Still, changing control systems is a challenge. Change can cause people to fear making mistakes, losing control. “Once operators learn a system they don’t want to give it up,” Gilbert said. What’s more, Haartz has high standards to maintain. With operations in the U.S., Mexico, Germany, India, China and Japan, changes at the headquarters plant can have a global impact.

Two things about Mahlo America gave the Haartz decision makers the encouragement they needed. “Although the system had all the bells and whistles a process engineer craves, the Windows Embedded-based interface is very intuitive,” Gilbert notes. “It’s so simple, our production crews took over after just 10 or 15 minutes of training. “Second, and probably most important, every person we met and spoke with at Mahlo knew their system thoroughly. And they totally understood our processes and challenges.”

Haartz installed its first Mahlo scanner in 2013 to test its performance in measuring total weight on a line producing material for nose and tire covers. As product requirements and challenges mounted, Haartz was easily able to assimilate Mahlo scanners into its other lines, measuring total weight, then film weight and laser thickness on the substrate, followed by full Auto Profile Control (APC) of the film weight. “The Mahlo APC gets up to production speed fast. Less material is wasted, and uptime maximized,” Gilbert noted. “Our crews and engineers were all in favor of the change.”

By the end of 2018. Haartz will have 15 Mahlo scanners online worldwide. “Lots of companies sell scanners that could probably meet our needs,” Gilbert states. “The real difference for us was the technical aptitude and service attitude of Mahlo’s people. Any time an issue comes up, Mahlo’s staff makes getting us back online their first priority.”

“Only twice since our first Haartz installation have we had to make an on-site service call,” notes Eric Reber, North American sales manager at Mahlo America Inc. “We have received the occasional call along the way, but these issues were addressed quickly through our TeamViewer service.”

The TeamViewer program is a secure remote-access service licensed with every Mahlo system sold. With it, users can give technicians temporary access to the control interface online in real time. This allows a technician to diagnose the system quickly and remotely. “TeamViewer can also be used to provide remote training for operators or engineers. Mahlo Telephone Support and TeamViewer service is included at no charge, around the clock, for the life of our system,” Reber notes.

Another feature on every Mahlo Auto Profile System is the die-bolt heater-failure alert. Haartz discovered that some of their legacy systems had quite a few dead die bolts and their graphs were giving them excessively averaged readings. “Mahlo systems graph in high resolution like a real-world sheet and give us an alert for any die bolt that’s not responding,” says Gilbert. “We’ve been able to reduce our scan-to-scan standard deviation to about 0.5% from greater than 2% previously. Also, seeing both the new scan and composite average on a single profile graph is a great feature.”

In addition to limiting waste in its manufacturing processes, Haartz strives to be “locally green” with its neighbors, communities and customers as one way to cut its carbon footprint. Haartz sources raw materials locally when possible, recycles TPO and PVC, and encourages carpooling. Continuous education and training, workplace safety, on-site fitness facilities and community-outreach programs are credited with keeping the average employee retention high.

“Maybe it’s a thing about family-operated companies, but we really like Mahlo’s simple, ‘Old World’ business approach.” Gilbert concluded, “Mahlo doesn't make machines in order to sell proprietary parts and service contracts. They engineer scanner systems that help support and strengthen our brand. That makes for a lasting business relationship.”

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreInjection Molder Bases Company Culture on Employee Empowerment

After more than two decades in the industry, Rodney Davenport was given the opportunity to create an injection molding operation in his own vision, and — in keeping with the product he was making — to do so from the ground up.

Read MoreGeneration Gap? Not at Packaging Personified

Started at a kitchen table and now in its third-generation of family involvement, this vertically integrated supplier of flexible packaging traces its success to closely aligning with customers and continually investing in new technology across its films, printing and converting operations.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More