5 Additive Manufacturing Trends to Watch in 2020

Plastics Technology spoke with HP, Carbon, EOS and Essentium to learn more about additive manufacturing trends in 2020.

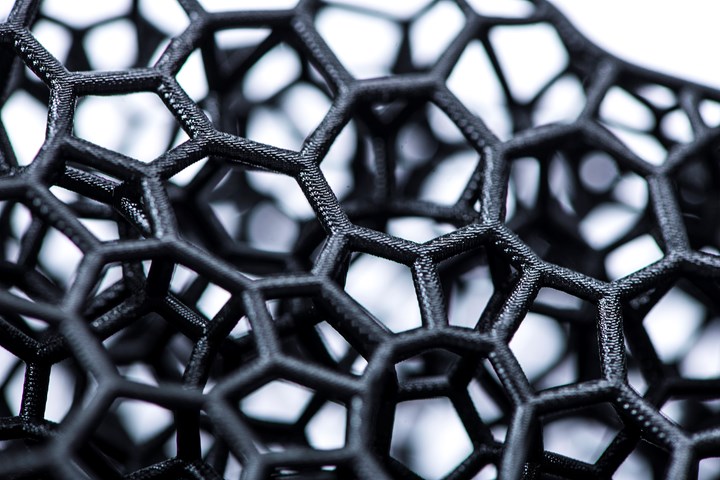

Close-up of Carbon, Riddell lattice structure to create a helmet liner. A key new development in 2019.

We saw lots of new 3D printing end-use applications in 2019. So what should we expect for the industry in 2020? Several 3D printing suppliers looked into their crystal balls to give predictions for next year. From there, I narrowed it down to five trends to watch for:

Additive Goes Mainstream

2020 predictions from Essentium on the future of industrial-scale additive manufacturing include seeing more industrial-scale 3D printing move into the manufacturing mainstream in a big way. “The promise of additive manufacturing (AM) has always been tremendous, but held back by unappealing economics, limitations in materials and production, and an inability to scale,” the company stated. “The latest 3D/AM printing platform innovations including hardware, software and materials are coming together to help companies manufacture in new ways – while removing all the historical barriers.”

The shift is already underway – new research commissioned by Essentium shows that two-thirds of companies reported they have more than doubled their use of industrial-scale AM over the past 12 months.

Shift Toward Automation

Paul Benning, Senior Fellow - 3D Print & Microfluidics Chief Technologist, HP, said that in 2020 and beyond, the 3D printing landscape will see a shift toward automation, using artificial intelligence and machine learning as a design aid.

“We have already seen a shift from 3D printing prototypes to production of final parts,” he said. “The biggest question is how quickly production solutions will scale and we think that the geography of digital manufacturing operations will be driven by both supply chain efficiencies and proximity to end users.”

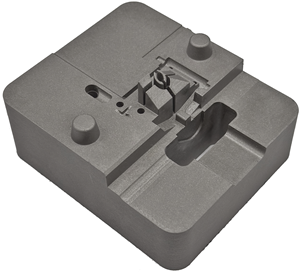

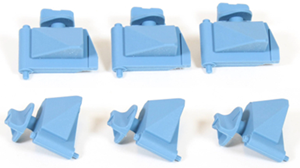

Benning says that when they look at examples of moving the production capability locally, those that provide the most value are the highest volume applications in the world today, such as dental liners. “The capability to deliver files digitally and produce products locally hasn’t always won out,” he said. “Manufacturers must examine where in the supply chain it’s most efficient to ship to final users and how that ties back to the economics of production.”

He cites one interesting example of this is from the 2D world around packaging. “Cardboard boxes provide a fascinating use case and growth market for digital prints, as there are interesting parallels for the 3D printing of final parts,” he said. “The corrugate box business is quite localized with production of boxes happening within a 150-200-mile circle of where the trees that are turned into corrugate once stood.”

Closer Collaborations

Fabian Krauss, who is leading the EOS polymer business in North America, predicts great growth in the industry and sees closer collaborations, especially with the further integration of AM with existing plastics manufacturing.

“Over the past 10 years, additive manufacturing is sometimes described as a ‘challenger’ to conventional plastics manufacturing,” he said. “But as it started in 2019, and we will see it more in 2020, it will be more complementary to injection molding and work hand-in-hand.”

While materials in the past for AM have been limiting, with new materials launching seemingly by the month, it will continue to open up new innovations.

Expansion of End-Markets

Carbon says that life sciences and healthcare hold huge opportunities for additive manufacturing. For example, Carbon believes there are opportunities to help reduce healthcare systems costs by supporting new approaches to treating diseases and improving the patient experience. “To accomplish this, we’re looking to work on applications including surgical tools and implants,” the company stated.

Krauss of EOS says that in 2020, there will be interesting launches in consumer goods, footwear and automotive as well as aerospace/interior applications.

Essentium believes that 2020 will mark the year that additive at scale transforms manufacturing across sectors including aerospace, automotive, electronics manufacturing services and biomedical.

Sustainability

With a push toward a circular economy, additive manufacturing also has a key role to play.

Benning of HP said that to meet customer needs, the manufacturing industry will continue to focus on catering offerings across industries and verticals to push industrialization forward. Material options available to customers for application production are a large component and with a heightened scrutiny on plastic waste, the 3D printing industry will continue to adjust its materials to meet customer sustainability needs, he said.

“At HP, using recycled materials as the base material for a new product is a work in progress,” he said. “Currently, we can reuse unfused powder in a Multi Jet Fusion system, and we can recycle 100% of printed parts into starting material for injection molding parts. Our vision is to be able to turn an existing part back into powder that can then be re-introduced to the machine. We’re not there yet as an industry in terms of recycling the part as opposed to just recycling the powder, but it’s certainly how we expect materials to evolve.”

Krauss of EOS, “We will see the importance of sustainability in AM in 2020. It’s been a key topic already in the overall plastics world; we saw this at the K fair. This is a topic we value and put emphasis on at EOS, which, to us, means no new waste in the processes of manufacturing components.” He also says this means using more biobased sources; and closing the cycle by using either recyclable or biodegradable materials in the product environment, when applicable.

Carbon says its also looking to develop more environmentally-conscious materials and processes.

Related Content

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreAdditive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More