Arevo to Produce 3D-Printed Carbon Fiber Unibody Bike Frames

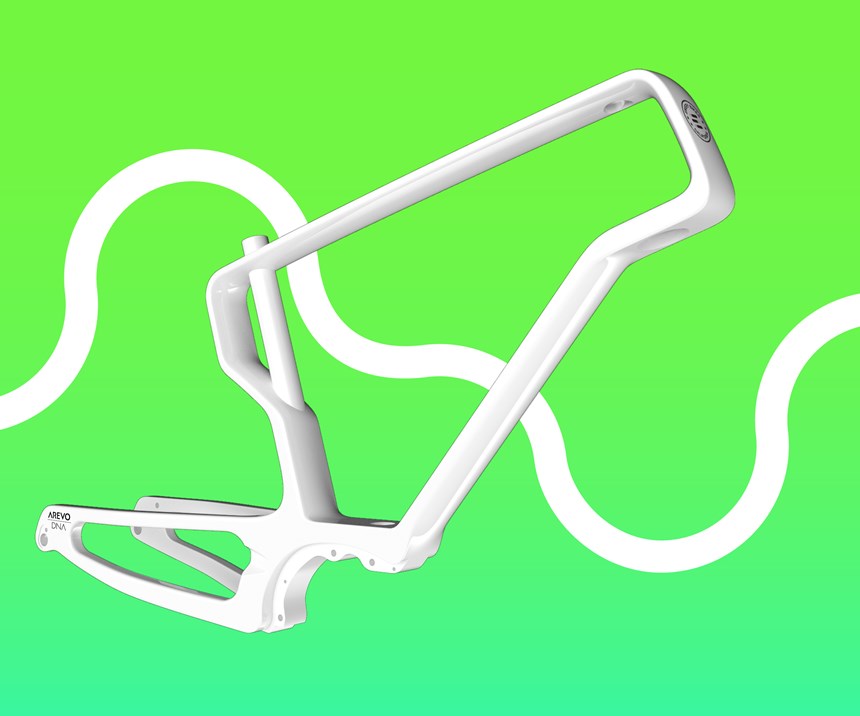

The Arevo frame is made as a single part, in contrast to current composite frames, which are made of many parts glued together.

Silicon Valley-based Arevo announced a partnership with boutique bike manufacturer Franco Bicycles to deliver a reported “world’s first” 3D printed, continuous carbon fiber single-piece unibody frame for a new line of eBikes Franco that will sell under the “Emery” brand.

Arevo DNA additive manufacturing (AM) technology features patented software algorithms enabling generative design techniques, free-motion robotics for “True 3D” construction, and direct energy deposition for virtually void free construction all optimized for anisotropic composite materials. For instance, the Arevo bike frame is made as a single part, in contrast to current composite frames, which are made of many parts glued together.

The Arevo DNA AM process takes the design and final manufacture of a bike frame from 18 months to just a few days at a significant reduction in product development costs. The frames are in production now at Arevo’s new multi-purpose facility in Milpitas.

The company believes that this represents several breakthroughs for bicycle manufacturers, with implications for other industries as well including true serial, volume production of AM-made composite parts. These parts are composed with thermoplastic materials, which are tougher, durable and recyclable, as compared to brittle and non-recyclable thermoset materials.

“This is the first composite additive-manufactured bike frame and it represents an important milestone for the AM industry as Arevo is delivering on the promise of on-demand manufacturing of composite parts in volume now,” says Hemant Bheda, Arevo Co-Founder and Chairman.

Related Content

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

-

Getting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.