Chassis and Powertrain Finalists from SPE Auto Innovation Awards

Judged parts cut weight and cost while adding functionality and endurance in high wear environments.

As I’ve reported previously, this years SPE Automotive Innovation Awards contest yielded some very interesting finalists in all nine categories. Here are a couple from the Chassis/Hardware and Powertrain categories, many of which are industry firsts, that merit mention and made it difficult for this participating judge to make a final choice.

Chassis/Hardware

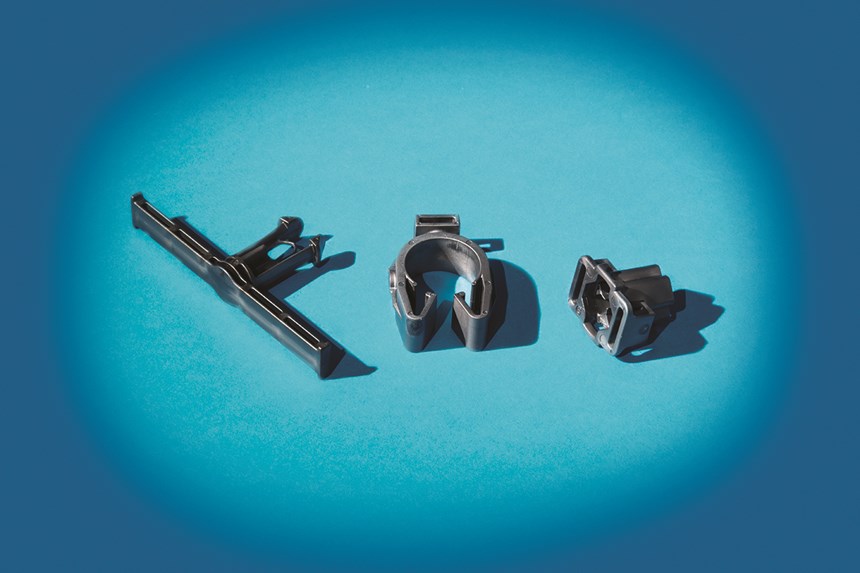

● Flexible PPS Fasteners for High-Heat Applications: This first-time application of replacing either metal and/or shielded nylon in high-heat fasteners appears in the 2018 Ford F-150 pickup. Using Fortran FX72T6 PPS from Celanese Tier I supplier/processor Lear Corp./Hellermann Tyton were able to achieve a 50% weight savings in this injection molded part via elimination of metal fasteners and shielding with substantial cost savings.

Flexibility was maintained after high-heat exposure without shielding and assembly, while ergonomics were improved. This technology is transferable to many high-heat harness applications underhood or near the exhaust.

● Engine Bracket: Appearing in the 2017 Daimler AG E-Klasse coupe, these engine brackets were injection molded of DuPont’s Zytel 70G50 HSLA, a 50% glass-reinforced nylon 66. Use of this material enabled ErlingKlinger to improve NVH (noise/vibration/harshness) in the powertrain.

An innovative injection molding tooling concept with 1 + 1 (including hot runner and pressure transducer for continuous process control for both the left and right side bracket) was developed for production. This is the first time two cavity tooling with a hot runner system plus two pressure transducers for each cavity, enabling the continuous monitoring of the process, have been utilized. A cost savings of up to 20% compared to metal brackets and up to 15% compared to aluminum brackets, was achieved.

● Plastic Clip for Door Integrated Window Regulators: Featured in Ford’s 2017 Fiesta subcompact, these industry first plastic clip attachments secure the IWR mechanism to the side doors (46 clips/vehicle). Injection molded of Celcon M-90, a medium viscosity acetal, and Elastollan C88A TPU, they replace metal fasteners and weld nuts for a weight savings of .44 lb/vehicle. Estimated cost savings include $350,000 for reduced cycle times, $210,000 for scrap cost elimination and $250,000 per plant as no tools are required. Customer benefits include improved fuel efficiency, better crash performance (energy absorption) due to the flexibility of the carrier, improved NVH and acoustic performance of the doors.

Powertrain

● Transmission Baffle: Featured in the 2018 Ford Focus compact, this new injection molded transmission baffle was the result of unique part geometry and CFD (Computational Fluid Dynamics) studies that enabled seal elements and fluid flow passages for improved transmission performance—not possible before in a stamped metal component. Ford, Toledo Molding and Dow utilized Hytrel 7246 TPE from DuPont Automotive.

Transmission efficiency was improved by 8% resulting in up to a 0.5 mpg economy gain. A reduction of 50% in weight and 40% on cost ($1/transmission) was gained compared to a metal part with molded seal elements. The TPE material is recyclable for a reduced carbon footprint.

Related Content

-

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

-

Prices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.

-

Prices of Volume Resins Drop--Except for PE

The downward trajectory appears to be continuing into the first quarter for most resin prices, though PE and possibly PP may remain somewhat stable.