Free Webinar on Plasma LSR Adhesion for Medical Devices

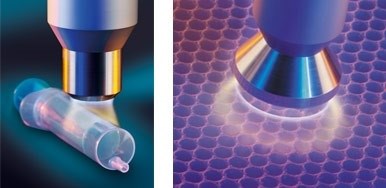

Plasmatreat's webinar addresses new LSR adhesion challenges for medical devices.

Liquid silicone rubbers (LSRs) have long been used in medical device manufacturing, since nearly every grade of LSR is biocompatible and available grades are specifically developed and approved for implants and similar medical applications. However, new high-performance substrates in combination with new two-shot injection molding techniques make adhesion of LSRs challenging.

According to Jeff Leighty, medical marketing manager for Plasmatreat North America, “Plasma helps overcome challenges stemming from both contamination of the substrate and from the inert substrate surface chemistry itself. Plasma opens the door for medical device manufacturers to design parts from a wider range of materials while reducing the risks of adhesion failure.”

Leighty explains how plasma improves LSR adhesion for medical devices in a free webinar offered by Plasmatreat that can been viewed at http://www.plasmatreat.com/webinars/adhesion-of-lsr.html.

Related Content

-

Allegheny Performance Plastics to Enter Health Care Sector

The custom molder has secured multiple projects in health care and will be adding cleanroom and white-room spaces, as well as injection molding machines, in support.

-

Industrial Resin Recycling Diversifies by Looking Beyond Automotive

Recycler equips for new business in medical, housewares and carpeting.

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.