Global Bioplastics Market to Grow by Over 15%

The European Bioplastics’ 2019 data update confirm dynamic growth for the bioplastics industry.

Earlier this month the results of the European Bioplastics’ annual market data update were presented at the 14th European Bioplastics Conference in Berlin, confirming dynamic growth of the global bioplastics industry. “In an increasingly environmentally conscious environment, the global market for bioplastics is predicted to grow by more than 15% over the next five years,” says Hasso von Pogrell, managing director of European Bioplastics.

The market data was compiled in cooperation with the German research institute nova-Institute. The data for the global production capacities of bioplastics are based on the market study “Bio-Based Building Blocks and Polymers” by nova-Institute (2020).

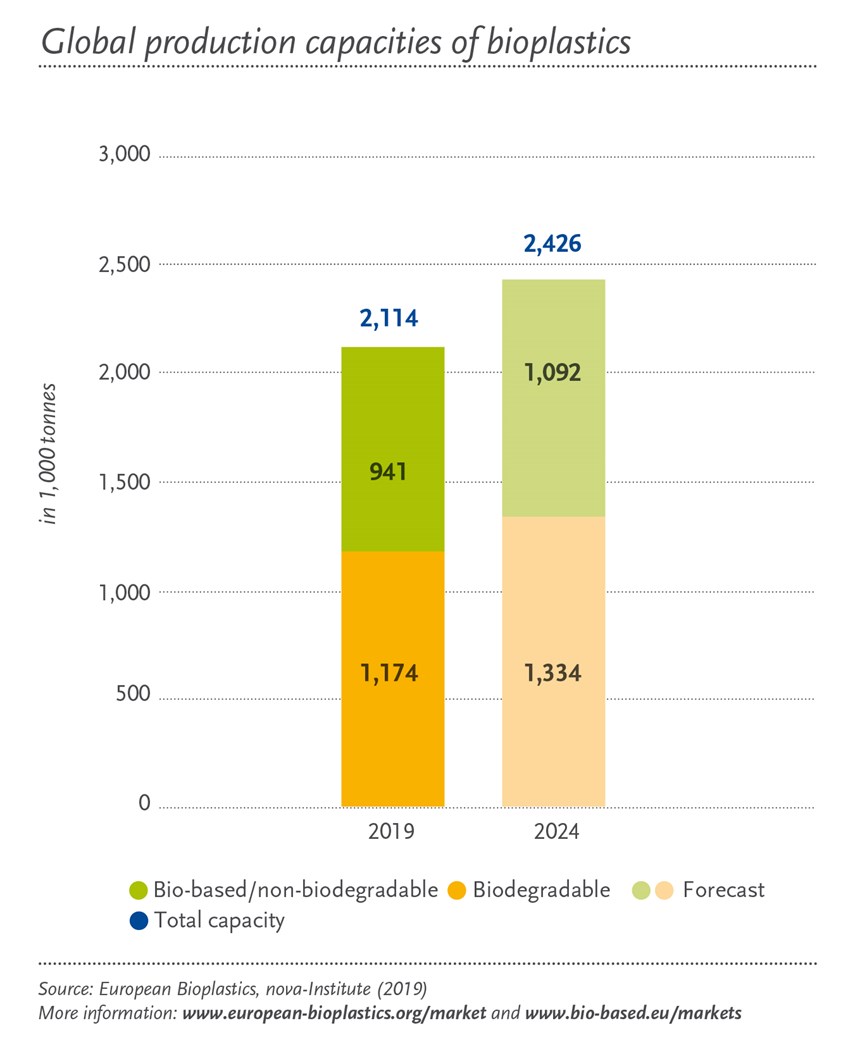

The global bioplastics production capacity is set to increase from around 2.1 million tonnes (4.2 billion lb) in 2019 to 2.4 million tonnes (4.8 billion/lb) in 2024. Innovative biopolymers such as PHAs (polyhydroxyalkanoates) and PP are driving this growth. PHAs are an important polymer family that entered the market at a larger commercial scale, which continues to increase. Production capacities are set to more than triple in the next five years. These polyesters are bio-based, biodegradable, and feature a wide array of physical and mechanical properties.

Production capacities of PP are set to almost grow sixfold by 2024. This is due to the widespread application of PP in a wide range of sectors. PP is a very versatile material that features excellent barrier properties. High-performance PP grades are an ideal replacement for several conventional fossil-based plastics, especially PE.

Bio-based, non-biodegradable plastics, including the drop-in solutions bio-based PE and bio-based PET, as well as bio-based nylons, currently comprise around 44% (almost 1 million tonnes/2 billion lb) of the global bioplastics production capacities. The production of bio-based PE is predicted to continue to grow as new capacities are planned to come on stream in Europe in the coming years.

In contrast, intentions to increase production capacities for bio-based PET have not been realized nearly at the rate predicted in previous years, but actually declined over the years. Instead, the focus has shifted to the development of PEF (polyethylene furanoate), a new polymer that is expected to enter the market in 2023. PEF is comparable to PET, but is fully bio-based and furthermore features superior barrier and thermal properties, making it an ideal material for beverage bottles.

Packaging remains the largest field of application for bioplastics with almost 53% (1.14 million tonnes/ 2.28 billion lb) of the total bioplastics market in 2019. The data also confirm that bioplastics materials are already being used in many other sectors, and the portfolio of applications continues to diversify. Segments, such as automotive & transport or building & construction, significantly increased their relative share.

With a view to regional capacity development, Asia remains a major production hub with over 45% of bioplastics currently produced there. Presently, one-fifth of the production capacity is located in Europe. This share is predicted to grow to up to 30% by 2024.

The land used to grow the renewable feedstock for the production of bioplastics is estimated to be 0.7 million hectares in 2019, and continues to account for only around 0.02 percent of the global agricultural area of 4.8 billion hectares. Despite the market growth predicted in the next five years, the land use share for bioplastics will remain at only around 0.02 percent. “The data show once more that there is no competition between renewable feedstock for food and feed, and the use for bioplastics," says Francois de Bie, chairman of European Bioplastics, "94% of all arable land is used for pasture, feed and food."

Related Content

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More