Here’s a Cost-Saving Tip for Measuring Mold Coolant Flow

Monitor mold-coolant flow with an ultrasonic sensor that clamps on the outside of the cooling line.

What is shaping up as an important trend in mold cooling is measuring and controlling not just coolant temperature, but flow rate as well. Another trend is toward use of external sensors for monitoring equipment without the trouble and expense of drilling holes into machine components.

These two trends intersected in a recent interview with engineers and managers of EVCO Plastics in DeForest, Wis., a major custom injection molder with nine plants in the U.S., Mexico and China. Among several new technological initiatives at the company, which will be detailed in a Processor’s Edge story in the January issue of Plastics Technology, one is an expansion of process monitoring of injection machines in the company’s medical molding operations. Besides archiving values of a handful of machine parameters on a central computer, EVCO is also gathering some auxiliary-equipment data, such as dryer temperatures and water flow and pressure from mold-temperature-control units (TCUs).

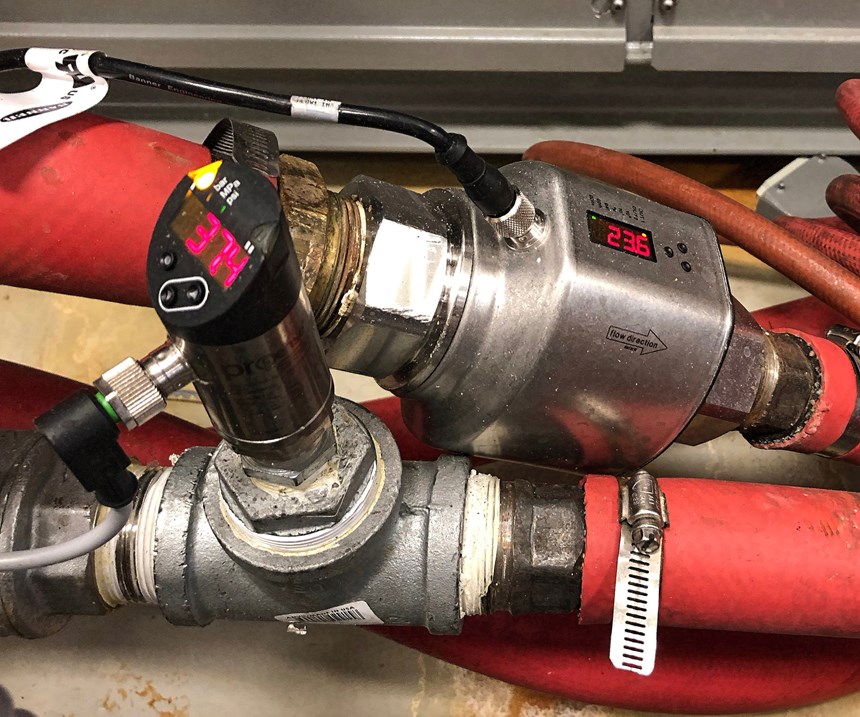

In discussing the water-flow data, EVCO automation engineer Jimmy Lee was particularly enthusiastic about use of ultrasonic flow sensors that are clamped on the outside of the water lines—“so you don’t have to break into the pipe,” Lee says. EVCO is using the FD-Q series sensor from Keyence Corp. of America, Itasca, Ill. It reportedly can be mounted on a pipe in 60 sec with six standard screws.

UPDATE: After writing this, I heard from Jimmy Lee, who told me that EVCO has switched to other types of sensors. “The clamp-on sensors did work, and it’s not that we woldn’t recommend them,” Lee said, but other sensors offered features the company needed. Though they don’t clamp on externally, ProSense sensors from Automationdirect.com offer a millivolt or 0-10V signal needed to connect to EVCO’s central monitoring system. And while the Keyence sensor measures only flow, EVCO is beta testing the ProSense EPS25-V145-1001 to measure coolant pressure and the ProSense FMM150-1001 for flow, with the ability to also measure temperature as an analog option. “With this flow and pressure data, boundaries can be set so that if any of these signals are out of range, the machine will shut down. This will prevent us from creating bad parts and taking immediate action to correct any problems that surface,” Lee explained.

Related Content

-

Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

-

ACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.

-

Temperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.