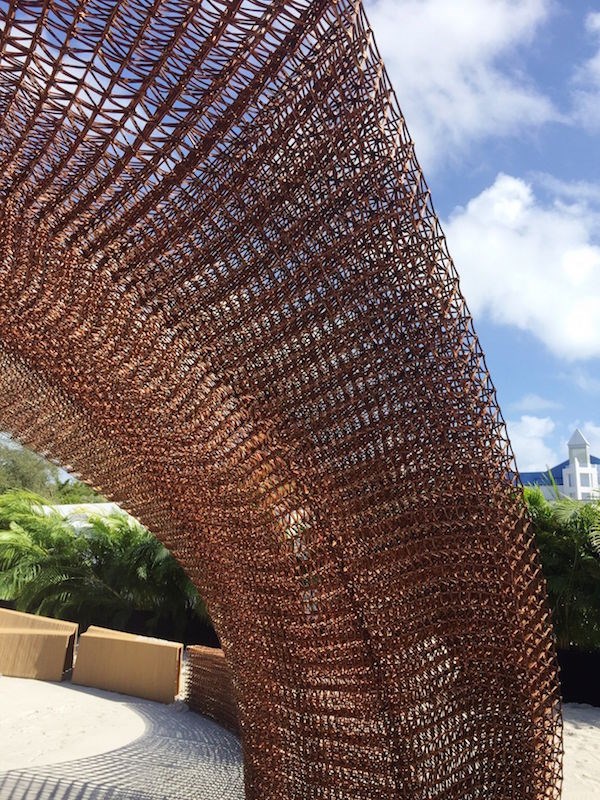

Large-Scale 3-D Printed Structure at Design Miami Show

Techmer ES partnered with ORNL to create this structure which utilizes a bamboo fiber-reinforced PLA.

Techmer ES partnered with ORNL to create this structure which utilizes a bamboo fiber-reinforced PLA.

It is heartening to see the continued “blossoming” of ongoing partnerships between private firms like Techmer ES (TES), Clinton, Tenn., wholly-owned subsidiary of Techmer PM, Branch Technology of Chattanooga, Tenn., and the Department of Energy’s Oak Ridge National Laboratory (ORNL) to advance additive manufacturing technology. The latest project of the partners was featured at the entry of the Design Miami’s pavilion held November 30 to December 4.

This large-scale 3-D printed structure utilized custom carbon fiber-reinforced ABS materials developed by TES, which helped build the installation’s arc canopy printed by Branch Technology, using its free-form 3-D printing technology.

Meanwhile, the seating and counter space were printed of TES’s bio-derived PLA compound that is reinforced with bamboo fibers. These components were printed in DOE’s Manufacturing Demonstration Facility located at ORNL using a Cincinnati Inc. Big Area Additive Manufacturing, or BAAM, machine.

“It’s exciting to design and produce high-performance materials for a one-of-a-kind structure…Within a four-week timeframe, we worked through challenges related to the PLA and bamboo fibers and successfully formulated materials that met the installation’s structural and extended outdoor durability needs,” said TES product development manager Alan Franc.

The PLA/bamboo-reinforced material is supplied by TES in the form of 1/8-inch pellets, like is the case with most of the company’s other materials, according to Tom Drye, managing director for TES. “The real magic lies in how we compound and formulate the material—this information is proprietary,” he adds.

It was just two years ago that we were all treated to the world’s first 3-D printed car that was designed by Local Motors and made its debut at IMTS 2014. A BAAM machine developed by ORNL and Cincinnati Inc., was used to produce the “Strati”. It extrudes hot thermoplastic to build parts layer-by-layer, similar to an FDM machine.

Following a further upgrade to BAAM, ORNL and TES developed the first full-size 3-D printed electric car. The fully-functioning, 1400-lb Shelby Cobra 289 FIA contains 500 lb of 3-D printed parts (the body of the vehicle) made from Electrafil J-1200/CF/20—a 20% carbon-fiber-reinforced ABS formulated by TES. The tooling was also made with that material.

Related Content

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.