Machine Guards Get in Your Way?

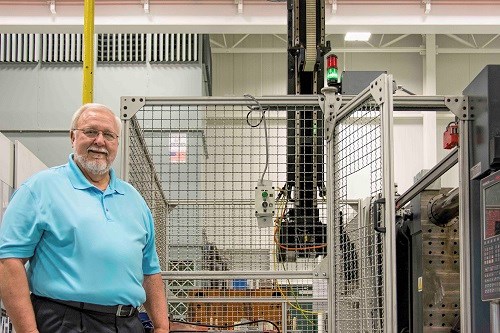

Easier access to the point where a robot deposits parts on a conveyor—that’s what Carl Morris, president and founder of Itech in Arden, N.C., is looking for.

Easier access to the point where a robot deposits parts on a conveyor—that’s what Carl Morris, president and founder of Itech in Arden, N.C., is looking for.

At his new plant expansion at the Itech South facility in Westminster, S.C., he will replace “hard” metal-screen guarding around the robot drop point with vision cameras that will detect when a human enters the safety zone and halt the robot. That way, there’s no delay to open up the guarding if an operator or technician needs to get to that location. This is just one element of his plans for increased automation at Itech and Itech South.

For more on the latest doings at Itech South, see my On-Site feature in the upcoming June issue.

Related Content

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.