New Additive Allows PE and PP to Combine Into New Alloy

One percent of new additive results in mechanically tougher PE/PP alloy and opens up mixed-stream recycling opportunities.

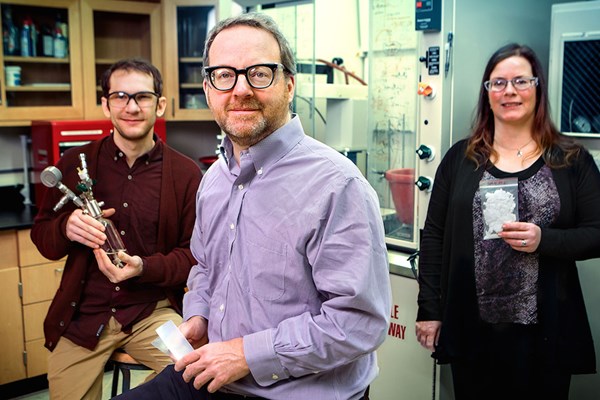

Researchers believe they have found a solution to meld PE and PP to create a new polymer. Geoffrey Coates, a professor of chemistry and chemical biology at Cornell University, and his group have collaborated with a group from the University of Minnesota to develop a multiblock polymer that, when added in small measure to a mix of the two otherwise incompatible materials, create a new and mechanically tough polymer. The two groups' work is detailed in a paper, "Combining polyethylene and polypropylene: Enhanced performance with PE/PP multiblock polymers," published online Feb. 23 in Science.

By adding a miniscule amount of their tetrablock (four-block) polymer—with alternating polyethylene and polypropylene segments—the resultant material reportedly has strength superior to diblock (two-block) polymers they tested.

In their test, two strips of plastic were welded together using different multi-block polymers as adhesives, then mechanically pulled apart. While the welds made with diblock polymers failed relatively quickly, the weld made of the group's tetrablock additive held so well that the plastic strips broke instead.

“People have done things like this before,” Coates says, “but they'll typically put 10 percent of a soft material, so you don't get the nice plastic properties, you get something that’s not quite as good as the original material.”

“What’s exciting about this,” he says, “is we can go to as low as 1 percent of our additive, and you get a plastic alloy that really has super-great properties.”

Eagan believes this tetrablock polymer show promise for improving recycling and it could also spawn a whole new class of mechanically tough polymer blends.

“If you could make a milk jug with 30 percent less material because it’s mechanically better, think of the sustainability of that,” he says. “You’re using less plastic, less oil, you have less stuff to recycle, you have a lighter product that uses less fossil fuel to move it.”

James Eagan, a postdoctoral researcher in Coates’ group, is lead author of the paper. Other collaborators included researcher Anne LaPointe and former visiting scientist Rocco DiGirolamo.

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.