Solvay to Fast-Track its Position in Additive Manufacturing

The combination of Sinterline technology and MMI Technyl Design is shaping the future of 3D printed functional automotive parts.

The combination of Sinterline technology and MMI Technyl Design is shaping the future of 3D printed functional automotive parts.

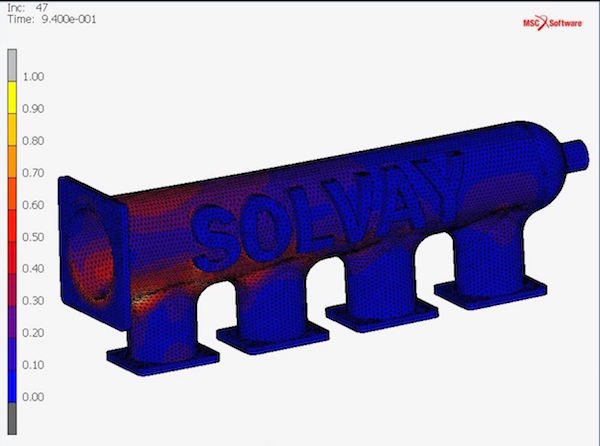

Last month, we reported on several materials-related news items announced by Solvay Engineering Plastics and Solvay Specialty Chemicals at K 2016. Among them was a 3D printed functional plenum chamber of an air intake manifold showcased by Solvay Engineering Polymers and designed for the Polimotor 2 racing car project. It is produced with the company’s Sinterline Technyl nylon 6 powder on an SLS machine.

The company has announced that it is strengthening its Sinterline Technyl nylon 6 offer for additive manufacturing of functional parts with the predictive simulation platform MMI Technyl Design. Having had a proven track record in injection molding technologies, the MMI Technyl Design platform now offers a step towards the design optimization of 3D printed technical parts.

In fact, the first time this predictive simulation tool was applied by Solvay was for the functional 3D printed Sinterline plenum chamber for the Polimotor 2 all-plastic engine project. The aim is to develop an engine weighing 138-148 lb) about 90 lb less than today’s standard production engine, thereby lowering fuel consumption and CO2 emisssions.

Said Matti Hotzberg, designer and leader of the Polimotor projects, “The plenum fabricated with Sinterline Technyl PA6 technology could easily perform without failure under real operating conditions. Integrating the 3D printed part with predictive simulation demonstrated all the additional benefits we could obtain to further reduce weight.”

The MMI Technyl Design tool coupled with a good understanding for the parameters of Sinterline materials and SLS printing processes showed the plenum’s original design could be up to 30% lighter than originally thought possible. Added Sinterline program leader Dominique Giannotta, “The successful validation of part performance modeling for PA6 3D printing will help boost the technology and change the traditional landscape of manufacturing. Enthusiastic feedback from major automotive industry players confirms their interest to accelerate this development in order to offer them a combined service in the near future.”

Related Content

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

DuPont Buys Medical Product Manufacturer Spectrum Plastics

Purchase price of $1.75 billion for leading supplier of extruded, molded, and 3D printed medical components.