‘There are no unskilled jobs here anymore’

That observation comes from Mary Ann Cervinka, HR manager Arrow Gear, and is found Accenture’s 2014 Manufacturing Skills and Training Study, appropriately entitled, “Out of Inventory: Skills Shortage Threatens Growth for U.S. Manufacturing.”

Completed in conjunction with the Manufacturing Institute, the study, which was conducted between August 2013 and January 2014, surveyed more than 300 manufacturing executives hailing from companies with an average annual revenue of $100 million.

Cervinka’s quote highlights the predicament those manufacturers currently find themselves in. The jobs they need to fill are becoming more and more complex while the pool of people who can do them becomes more and more shallow.

The survey found that 80% of manufacturers reported a moderate to severe shortage in finding highly skilled workers, while at the same time, skilled and highly skilled roles make up 80% of their workforce.

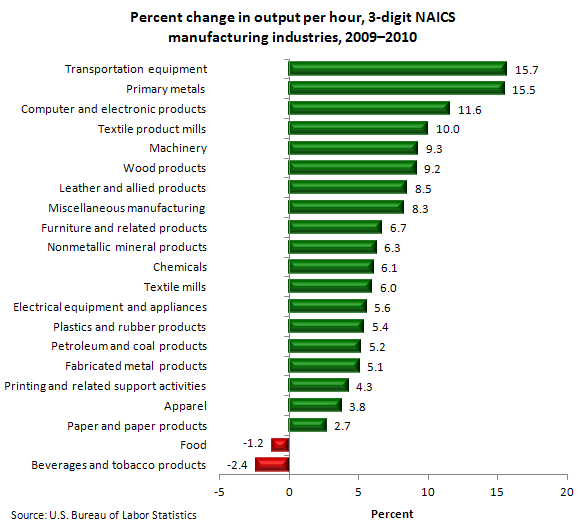

As these companies face a labor shortfall, many are simultaneously attempting to boost production. According to the report, more than 50% of companies reported plans to increase U.S. based production by at least 5% in the next five years. In general, the U.S. manufacturing sector has enjoyed an annual growth rate of 7.7% between 2009 and 2011, reaching its highest level ever at more than $5.4 trillion in 2011, according to the U.S. Bureau of Economic Analysis – Manufacturing Industry Data. Productivity in the U.S. has jumped nearly 20% from 2001 to 2011, increasing is every year save two—2008 and 2009—according to U.S. Bureau of Labor Statistics cited by Accenture.

That’s despite the very real, and detrimental, impact of too few skilled workers. According to the report, 62% of respondents saw an increase in production downtime of 5% or more, while 66% reported cycle time increases of 5% or more.

Survey participants are actively working to address the gap, however, with almost 10% spending more than $5,000 annually per employee on skills training, with the average respondent spending about $1,000 annually per employee for skills training.

The report also identified some best practices companies are deploying to address the skills shortfall.

Digital learning experiences—“Embracing digital technologies to offer learning experiences anytime, anywhere.”

Combine formal and informal training—“All of the leading companies we interviewed had some form of established relationships with local community colleges or vocational technical programs.”

Use a certification approach to skills building—“Not only do employers gain confidence that their employees are able to perform at a given level of skill, employees gain confidence in their own abilities as they acquire new skills certifications.”

The bottom line is the gap is actually impacting companies’ bottom lines, with the report finding that earnings were reduced up to 11% annually due to increased production costs and revenue losses due to skills shortages. The problem will only get worse, with the U.S. Department of Labor stating the average age of manufacturing labor was 44.1 years in 2011.

In our September issue, Plastics Technology will see how some plastics processors are attempting to bridge the gap. Does your company have a contingency plan?

Related Content

-

Blow Molder with a Mission: CKS Packaging Shares Gains Of Its Phenomenal Growth

From three machines in 1986 to 27 plants nationwide today, this family-owned processor has prospered through unwavering customer service, committed employees and dedicated service to its community.

-

Plastics Processors Who Hire ‘Second-Chance’ Workers Do Well by Doing Good

Two blow molders with long-standing programs of hiring formerly incarcerated low-level offenders have helped these individuals re-enter their communities and have benefited from an additional resource during chronic labor shortages.

-

The Cost of High Employee Turnover in Injection Molding: Why Retention Matters

Starting in molding in 1993 and clocking in for nearly every job on the floor over the intervening decades, I’ve seen all sides of the hiring, training and retention process in the industry. Here are my thoughts on how to keep your most important asset — your people.