Transforming Recycled Plastic into Additives for Industrial and Consumer Products

GreenMantra out of Canada is a rapidly growing clean technology company that produces specialty polymer additives from recycled plastics.

With a more increased focus on adding more recycled content to products, it’s becoming very apparent that innovation is required in order to meet these demands. During the Plastics Recycling Conference, Canadian cleantech company GreenMantra Technologies accepted the Association of Plastics Recyclers (APR) Showcase Award, which is given to companies who have a innovative and potentially game-changing idea to advance the recycling of plastics.

During the conference, Plastics Technology México Editor-in-Chief Natalia Ortega and I sat down with Domenic Di Mondo, Vice President Technology and Business Development, to learn more about this growing company.

Inside GreenMantra’s facility in Brantford, Ontario.

GreenMantra Technologies is a clean technology company that utilizes a proprietary catalyst and patented depolymerization process to upcycle and transform recycled plastics into value-added synthetic waxes and specialty polymers.

“As a company, we started in 2010. At that point, we had a concept of the technology. This was the origin of the term ‘chemical recycling’ that people are using now, which is also referred to as ‘advanced recycling,’” Di Mondo said. “It's very basically defined as technologies that change the structure of plastic or do something on a more molecular level, as opposed to just remelting [as with mechanical recycling]. That's the core of the technology we developed.”

The company started in 2010 and built a lab process that they validated and then took to a demonstration scale. They are reportedly the first company in the world to upcycle post-consumer and post-industrial recycled plastics into synthetic polymers and additives that meet specific performance requirements for industrial applications. Utilizing its proprietary thermo-catalytic system and patented process, GreenMantra transforms recycled plastics into value-added waxes and specialty polymers for industrial applications such as roofing, roads, plastic composites and polymer processing.

“We're redesigning the molecule to create these new specialty polymers,” Di Mondo said. “What's interesting is it allows us to take these non-uniform, discarded plastics and make a very uniform high-quality synthetic wax that actually has novel applications.”

Scaling Production

GreenMantra is growing rapidly and expanding its manufacturing facilities in Brantford, Ontario to meet demand for performance additives.

Since 2016, GreenMantra been operating facilities 24/7 and making large quantities of products that are going out into markets across North America. And now this year, they’re expanding their commercial footprint into Europe as well.

GreenMantra’s synthetic wax might look similar to a plastic pellet, but the properties are radically different.

DiMondo explained the process as this:

“We take the discarded plastics and produce an end product that is a synthetic wax. We do that with both polyethylene and polypropylene on a commercial scale. So it actually comes out of our process, looking similar to pellets of plastic, but the properties are completely different from the starting material. That allows us to create a novel raw material that other manufacturers use in their process as a performance-enhancing additive.”

For the first eight years, the company was focused on working with polyethylene and polypropylene and when it saw success, it wanted to push the boundaries of its technology. About two years ago, the company introduced new technology around waste polystyrene.

“We asked ourselves, ‘can we do something with polystyrene?’ since this waste stream is essentially going to landfill and doesn't have a great outlet. We built a technology to do the same kind of thing,” he said. “But instead of making synthetic waxes [as we do with polyethylene and polypropelene], we make very novel styrenic polymers. This opens up the door to a whole new set of applications and end customers. It allowed us to diversify the portfolio further and to extend our platform and technology.”

Last year, the company announced a partnership with Ineos Styrolution that will align GreenMantra’s patented technology and Ineos Styrolution’s manufacturing infrastructure to convert waste polystyrene into chemical monomer building blocks.

GreenMantra purchases the discarded plastic by leveraging the existing mechanical recycling network in North America and also working with processors.

Di Mondo said that the company works with different Consumer Packaged Goods (CPGs) on ways to help them use more recycled content.

“We’ll ask, ‘okay, what's the challenge you're facing --- is it putting traditional recycled content in the bottle, in the bag, or in the container?’ If the issue is performance or a negative impact on process efficiency, (which reduces the output and increases the overall cost for manufacturers), that's where we can come in and say, ‘okay, we have an additive that you can use at 1 to 4 percent, which is exciting because that in and of itself counts as recycled plastic. But on top of that, it also gives you that ‘multiplier effect’. Now you can put in that 40 percent recycled plastic instead of virgin, and not have to worry about losing 20% in your output or making inferior products.”

Related Content

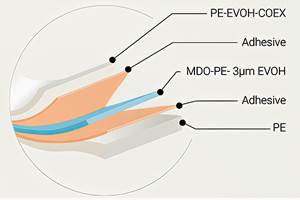

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreOptical Sorting for Color Flexibility in Recycled Plastics

Aaron Industries added optical sorting to its operation, expanding capabilities to meet the color needs of customers.

Read MoreRecycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreRead Next

What Is the Circular Economy?

In this video from K 2019, hear NOVA Chemicals, TOMRA, Covestro, Rapid Granulator and SABIC each discuss plastics’ role in the circular economy.

Read MorePP Waxes with Unique & Customizable Technical Properties

GreenMantra’s new PP waxes are among the high-value products from waste plastics it makes.

Read More