What Are the Most Important Issues Facing Processors?

Find out what the top issues facing processors are (hint: quality, energy use and the skills gap are involved), plus see reader suggestions on how to improve NPE.

In advance of NPE2015, Plastics Technology surveyed its readers regarding their operations, the show, and what the most important issues facing them are, garnering some interesting responses.

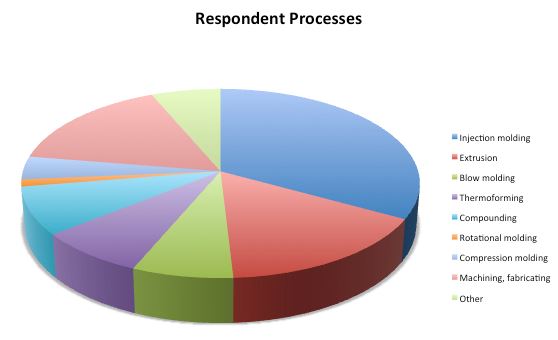

Nearly 230 individuals responded to the survey, and in terms of the processes performed in house, injection molding lead the way, at 60%, followed by extrusion and machining/fabricating (both at 29%); compounding and thermoforming (both at 14%), with blow molding (13%) close behind. Compression molding (7%) and rotational molding (2%) rounded out the respondent pool.

Quality, quality, quality

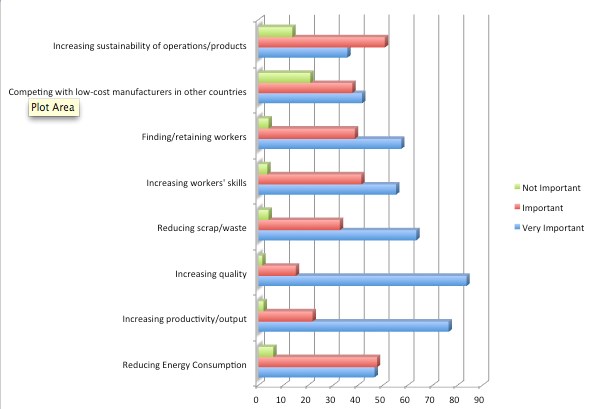

Just like the old Ford slogan, “Quality is Job One” for our survey participants, with 83% calling increasing manufacturing quality “very important.” Up next was increasing productivity/output (76%), followed by reducing scrap/material waste (63%). The skills gap, which Plastics Technology has covered extensively, is also top of mind for our readers. Just over 57% said finding/retaining skilled workers was very important, with 55% calling increasing their workers’ skills a top priority.

Rounding out the list were reducing energy consumption (46%), competing with low-cost manufacturers in other countries (41%), and increasing sustainability or operations/products (35%).

What About Safety?

Perhaps as interesting as what our readers checked off, were the topics respondents added in via comments. Leading the way? Safety. Four commenters noted that plant safety was a top concern for them, with additional write-ins including freight rates, developing new/better products, and preventative maintenance.

Making NPE better

The crux of the survey dealt with SPI’s triennial plastics event, NPE, and will be highlighted in a feature article that will run in Plastics Technology’s November issue. From those questions two things were clear: lots of folks have been to the show (83% said that they or others at their company had attended), and a lot more people will be headed to Orlando come March (nearly 61% said that they, or someone from their company, would go to NPE2015).

We also asked survey participants how they would improve the show, and a theme emerged. In so many words: Make NPE more like K. At least, make it like K in how the show is organized, with like technologies in the same hall (guessing folks wouldn’t want to recreate Düsseldorf weather in October or jam-packed U-bahn cars).

Here’s a sampling:

Set up floor so that all like manufacturers are in the same location.

Put like machinery/processes together instead of having it spread around. Do it like the K show.

Arrange the show by category, machines, secondary equipment, quality equipment, robotics, material handling.”

Group the technology providers closely together; they compete directly in the market place so there should be no problem with their booth areas all being together.

For the upcoming article, Plastics Technology spoke with SPI Trade Show Sales and Marketing Director Brad Williams, who acknowledged that show floor product categories will be a “big discussion” with NPE2015’s exhibit committee following the 2015 event. Whether that leads to a change in layout remains to be seen.

It should also be noted, that more than a few respondents were perfectly happy with the show as is:

No changes. I already find NPE to be the most useful trade show in the U.S. for my needs.

Read Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More