What Comes After MES? It’s Already Here

If you’re not sure what the initials M-E-S mean, or whether that’s something your business needs, it may be time to look beyond MES to the next generation of manufacturing connectivity.

Manufacturing Execution Systems, abbreviated MES, may not be the sort of topic that excites everyone, but there are lots of managers and supervisors and engineers in plastics operations that have grown to appreciate the value of real-time manufacturing data, available anywhere, anytime, to anyone who needs it. As we have reported in recent articles, real-time manufacturing visibility is making operations more efficient, productive and profitable. However, a number of these recent articles have focused on machine monitoring, which is not the same as MES and maybe something quite different – even something that represents a new alternative to MES.

What is MES? Let me borrow a definition from Bill Bither, cofounder and CEO of MachineMetrics in Northampton, Mass.: “A manufacturing operations management system that monitors, controls and documents the transformation ofraw materials into product in real time.” It “captures shop-floor execution data in real time; tracks production, maintenance, quality and inventory in real time; informs business planning and logistics (ERP).”

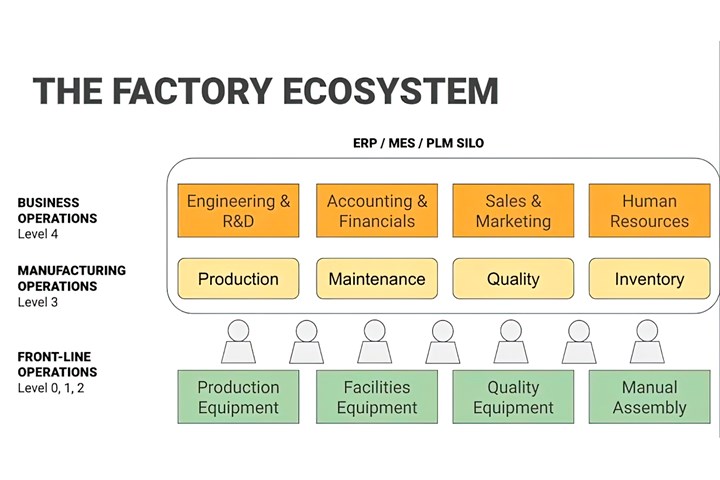

A “siloed” hierarchical software system is typical of today’s factories, says MachineMetrics. (Photos: MachineMetrics)

In other words, MES is a layer of operations management software (level 3 in the Factory Ecosystem diagram from MachineMetrics) above the shop-floor equipment (levels 0-2) and below the business software for Enterprise Resource Planning (ERP, level 4), which handles supply chain, procurement, accounting, finance, capital and operating expenses, marketing, human resources, payroll and customer management.

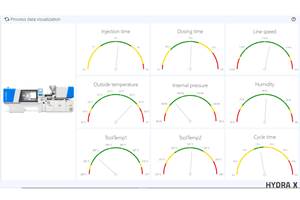

I heard Bither speak in a webinar this week, presented by our sister publication, Modern Machine Shop. His talk was provocatively titled, “The Death of MES (as We Know It) and the Rise of the Connected Factory.” His talk was a revelation for me, because it crystallized some vague ideas that had been floating in my head in recent weeks, when I had been reporting on a new generation of affordable, easy-to-use machine-monitoring systems from recently established companies like Guidewheel, Datanomix and IMM-Data. MachineMetrics, an eight-year-old firm that has hundreds of customers in metalworking and plastics, evidently belongs in the same category. What they all have in common are systems that require no programming or IT experience; can be implemented quickly and easily “out of the box”; extract operating data directly from machines of all types; are supplied on a subscription basis (“software as a service”), so there is little upfront investment and software is always up to date; and are web-based with data storage in the “cloud,” so they provide real-time data whenever and wherever needed. That data includes OEE and its components – uptime/downtime, downtime causes, cycle times and counts, part counts/job completion, etc. – all available in easy-to-read online dashboards.

Bither and other proponents of these new shop-floor machine-monitoring systems see a need to serve small to medium-sized companies with more accessible solutions than huge, multi-functional ERP and MES systems that are costly and time-consuming to implement, require on-site IT resources and both upfront and ongoing training. The new-generation monitoring systems are also said to be distinguished by their flexibility and scaleability and by being “hands-off” – requiring little to no manual input.

Bither said there has been such demand for more user-friendly shop-floor management software that a number of companies have tried to build it themselves — usually with disappointing results. Eighty percent of such efforts fail, Bither claimed. And while it’s quite natural, he says, to prefer keeping all your data in-house, Bither states that most data breaches occur at the user level and that remote storage by established “cloud” providers is actually more secure, especially when you consider the risk of catastrophic data loss from fire or flood.

Bither sees another factor driving demand for a new kind of production-monitoring software. While some buyers might value dealing with a single vendor, he sees multifunctional, “do-it-all” MES and MRP systems as “jack of all trades and master of none.” By trying to do so much, they don’t do a lot of things as well as more specialized software dedicated to one type of task – maintenance, job scheduling, billing, etc. We have even seen some older makers of machine-monitoring software adding MES-style capabilities, while some MES providers have extended their reach down to shop-floor machine monitoring. There may be another way.

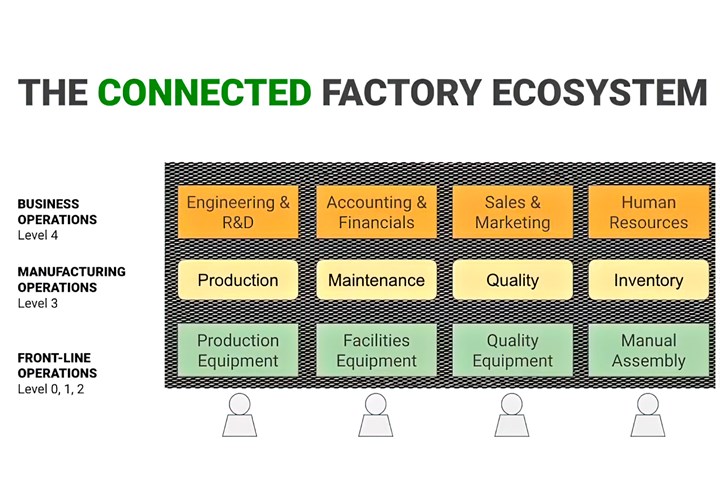

A less layered approach with free interconnectivity of specialized software modules is the new paradigm, according to MachineMetrics.

The solution, Bither proposes, is a new kind of factory ecosystem with a less rigidly layered hierarchical approach – a connected factory ecosystem, as shown in the second MachineMetrics diagram. In this less “siloed” conception, specialized software for shop-floor machine monitoring (like MachineMetrics, etc.) communicates freely with other apps dedicated to specific tasks on the shop floor (quality, plant utilities, manual assembly) and for tasks previously embedded in MES and ERP systems (maintenance, quality, inventory, accounting, sales, HR, etc.). This is an approach already used by MachineMetrics with a number of other software partners, though its machine-monitoring module also can integrate with existing MES and ERP systems.

So, maybe we are witnessing an evolution in manufacturing management software analogous to what we saw in corporate management, where the pendulum swung from a period of diversification into conglomerates with heterogeneous business units from manufacturing to movie theaters back to the current trend of de-conglomeration divestment into more focused businesses.

Whether or not you accept that 30,000-ft view of overall trends, there’s no question that small to medium-size manufacturers are enjoying a spate of new offerings that will help them participate in the new era’s motto: “Data is profit.”

Related Content

Beyond the Work Center: Using MES for Data-Driven Decisions Across Manufacturing Operations

Move past “is the job running” and “will it finish on time,” and apply MES to inform workflows ranging from accounting, inventory control, planning, material logistics, quality assurance, engineering and shipping.

Read MoreMold Monitor Adds Wireless Connectivity

NPE2024: Progressive’s CVe OnDemand software now offers wireless connectivity.

Read MoreEquipment Suppliers Show Adaptability and Smarts at TaipeiPlas 2024

Customizable equipment solutions, warm hand-off support, and seamless software integrations highlight Taiwan’s plastics show.

Read MoreManufacturers’ Superpower: ‘X-Ray Vision’ into Your Processes

Meet a ‘new’ name (to North American processors) in MES software, which provides a simple, modular way to achieve visibility into your production operations.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More