3D Printing is Merged with Printed Electronics

Revolutionary "Smart Wing" Created for UAV Model Demonstrates Groundbreaking Technology From Stratasys and Optomec

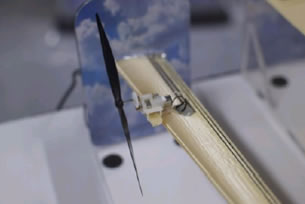

MINNEAPOLIS--(BUSINESS WIRE)-- (Nasdaq: SSYS) Stratasys and Optomec Inc. today announced that the companies have successfully completed a joint development project to merge 3D printing and printed electronics to create the world's first fully printed hybrid structure.

The first project, the development of a "smart wing" for an unmanned aerial vehicle (UAV) model with functional electronics is a

revolutionary event that has the potential to change product development in industries including medical device, consumer

electronics, automotive and aerospace. A video on stratasys.com discusses the making of hybrid structures.

"Bringing together 3D printing and printed electronic circuitry will be a game changer for design and manufacturing," says Jeff

DeGrange, VP of direct digital manufacturing at Stratasys. "It has the potential to completely streamline production by requiring fewer materials and steps to bring a product to market."

An Optomec Aerosol Jet system was used to print a conformal sensor, antenna and circuitry directly onto the wing of a UAV model. The wing was 3D printed with the Stratasys Fused Deposition Modeling (FDM) process. The electrical and sensor designs were provided by Aurora Flight Sciences, a supplier ofUAVs. "

We envision many potential applications of the Stratasys-Optomec approach for hybrid direct digital manufacturing," said David

Kordonowy, who leads Aurora Flight Sciences' Aerostructures Research Group. "The ability to fabricate functional electronics

into complex-shaped structures using additive manufacturing can allow UAVs to be built more quickly, with more customization,

potentially closer to the field where they're needed. All these benefits can lead to efficient, cost-effective fielded vehicles."

The combination of FDM 3D printing and printed electronics technologies can provide benefits over traditional prototyping,

manufacturing and field repair processes. Performance and functionality of products can be improved in two ways: 3D printers

enable lighter weight mechanical structures; and conformal electronics printed directly onto the structure frees up space for

additional payload. In turn, the process has a positive impact on the environment by using fewer materials.

"Manufacturers can implement this hybrid technology in a multitude of applications, not just in aerospace," says Optomec's Ken

Vartanian. "This technology can benefit numerous industries by allowing thinner, lighter, fully functional structures that cost less

to manufacture."

Optomec is the world-leading provider of additive manufacturing solutions for high-performance applications in the electronics,

solar, medical, and aerospace & defense markets. These systems utilize Optomec's patented Aerosol Jet Printed Electronics

technology and LENS powder-metal fabrication technology. The company has a global customer base of more than 100 users

that includes many industry-leading manufacturers. Online at: www.Optomec.com

Stratasys Inc., Minneapolis, is a maker of additive manufacturing machines for prototyping and producing plastic parts. The

company markets under the brands uPrint and Dimension 3D Printers and Fortus Production 3D Printers. The company also

operates RedEye On Demand, a digital-manufacturing service for prototypes and production parts. Stratasys manufactures 3D

printers for Hewlett Packard, which it sells under the brand Designjet3D. In 2011 Stratasys acquired 3D printer maker

Solidscape Inc. According to Wohlers Report 2011, Stratasys had a 41-percent market share in 2010, and has been the unit market leader for the ninth consecutive year. Stratasys patented and owns the Fused Deposition Modeling (FDM®) process.

The process creates functional prototypes and manufactured goods directly from any 3D CAD program, using highperformance

industrial thermoplastics. The company holds more than 285 granted or pending additive manufacturing patents

globally. Stratasys products are used in the aerospace, defense, automotive, medical, business and industrial equipment,

education, architecture, and consumer-product industries.