Blender Accessories

No two blending applications are exactly the same. So to match your blender to your specific installation, materials, and process, a wide range of accessories are available.

Some popular examples include:

Floor Stand:

The popular weigh scale blender is generally designed to be mounted on a process machine in order to minimize material handling prior to processing. But, in some cases, a floor stand is helpful to allow blending off the machine. Several models are available for use over barrels, gaylords or for automatic material removal by a conveying system employing a vacuum take-off box.

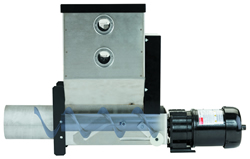

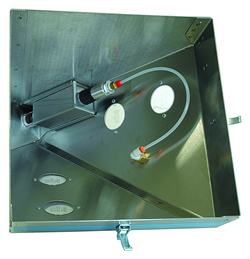

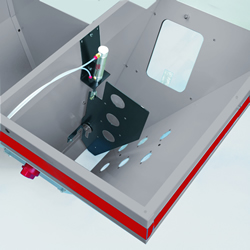

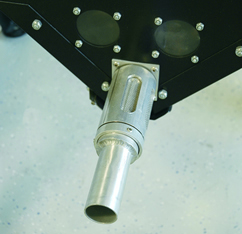

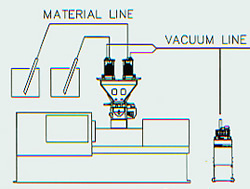

Vacuum take-off:

When installed away from the processing machine, a vacuum take-off box (also called a distribution box) may be employed below a floor stand to allow the supply of blended material to be generated by the demand of a conveying system, usually connected to a processing machine loader or receiver. This box may be equipped with one or several material outlets, and all may be connected to their own vacuum systems requiring the blended material. Typically, these probes, which come in different diameters for different size conveying systems, are air-to-material adjustable for the smoothest conveying performance.

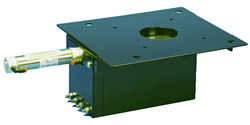

Flow Control Valves:

Blenders that are situated on floor stands above open containers, often employ a valve below them to permit an adequate residence time for blending before the blended material is permitted to free-flow from the blender. These pneumatic gate valves hold back the material in the blending chamber until it is thoroughly mixed and then opens to release the blend to the vessel below.

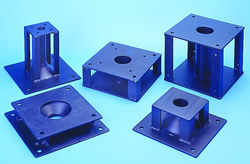

Machine Mount Adaptors:

Blenders mounted to molding machine or extruder throats typically require the use of some form of adaptor plate or riser to accommodate differences in the base of the blender and the machine throat. These adaptors range from simple plates equipped with mating bolt hole patterns to risers that funnel a larger blender discharge opening down to a smaller machine inlet without allowing for ledges that can retard or even hold material, which can cause cross-contamination of materials when changing blends.

Supply Hopper Extensions:

Variations to the supply hoppers to accommodate extra capacity or just a change in the loading equipment are often required to appropriately match the needs of a standard blender to a specific application. In some cases, a whole new hopper may be fitted, but in other cases, a simple extension of that hopper will accommodate the need by simply providing extra material capacity and/or the needs of the device(s) to be fitted onto the supply hopper.

Surge Hoppers:

A surge hopper provides a reserve of blended material so that material can continue to be fed to the process in the event of a disruption of material flow to and through the blender. Similar in function to blenders fitted with a floor stand above a barrel or gaylord.

Low level Alarms:

The goal of processors employing blending systems is to provide a totally automatic blending system. The use of a low level alarm to assure an uninterrupted supply of materials to and through the blender is often a high value investment. These alarms will monitor and alert the operator in the event of any lack of material flow, before or after the blending process so that process material flow is never interrupted. Problems can be addressed in advance of process interruption, depending upon where the low level signaling devices are located.

Spare Material Supply Hoppers:

Spare hoppers can be employed with blenders equipped with the provision for removable hoppers. They are typically pre-charged with a quantity of material (typically color) for easy replenishment or even rapid color changes. When changing color, changeover time is minimized since no clean out is required for the supply hopper. The entire hopper is simply replaced.

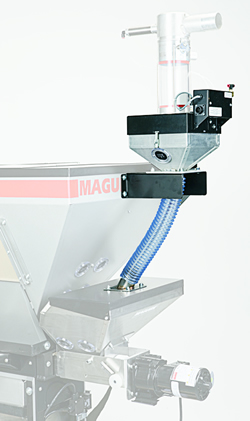

Automatic Loading Systems:

Loading systems maybe employed to keep supply hoppers full and material flow to the blender completely automated. They are duty-matched to the material and throughput required for each supply bin.

Selections include:

Venturi Loaders: These are small throughput, air operated loaders equipped with small cyclones and fed by the push of material into them from sources located close to the blender. They are typically simple, light-weight and uncomplicated. They are used for color concentrate, regrind and virgin materials, in low throughput quantities.

Self-contained vacuum loaders: These self-contained vacuum loaders use a powerful vacuum motor to draw material from sources at close to moderate distances and at medium throughputs. Their vacuum motor brushes require periodic maintenance, along with their filters, which are often equipped with a filter cleaning air blast system. There are also brushless models. Used for all materials, in moderation.

Some blender manufacturers provide optional lifting accommodations for the top mounted loaders, to facilitate blender bin cleanout and even loader maintenance, without the need for removing the loader(s) from the blender.

Vacuum Receivers:

Vacuum receivers are part of larger, central vacuum systems. They are utilized for the highest throughputs and the least maintenance. The centralized vacuum pump, filter and controls are typically located elsewhere, making the installation and use of these devices simple.

Add-on Dosing Feeders:

Some blender configurations allow for the addition of smaller dosing feeders to expand the number of materials that may be blended. These modular blender designs also permit the user to change the entire feeding system at color change time vs. cleaning out the existing feeder. In some cases, add-on feeders allow the use of a different material composition that cannot be accommodated by the existing dosing unit, like color concentrate, fine powders or irregular regrind.

Pellet & Powder valve options for hoppers

Manufacturers offer a wide range of flow valve designs to control the dispensing of pellets, powders, regrind and flake from blender hoppers. Dispense capabilities can range from less than a gram to hundreds of kilograms per minute. Some valve designs are better than others so processors should not hesitate to ask for references before agreeing to the purchase of dispense valves. Here are a few of the valve designs available:

- Vertical Valve for additive and colorant bins

- MicroPulse Valve for pellet dispenses of 0.1 g to about 2.5 g/sec.

- High Flow Corner Valve for pellets or regrind for dispenses of up to 11,999 gr./sec.

- Low Flow Pivot Valve mostly for pellets and regrind – flow rate up to 2,000 gr./sec.

- Wood Flour/Powder Feeder – Flow rate to 3 ft.3 (85 liters/min.)

Material Flow Aids: Although gravimetric blenders will compensate and even create an alarm condition in the event of material flow interruptions, the blenders works best with dry, free flowing materials. But since materials are sometimes dusty (IE: regrind) or bridge within the slanted walls of supply hoppers, flow aid accessories are available to overcome these conditions:

Provides a vertical wall inside the supply hopper, giving materials a steep sliding surface to encourage flow. High performance versions of this accessory pneumatically move up and down during dispensing and include windows that allow material entrapment that is then un-bridged as the wall moves.