What Is an All-Electric Injection Molding Machine?

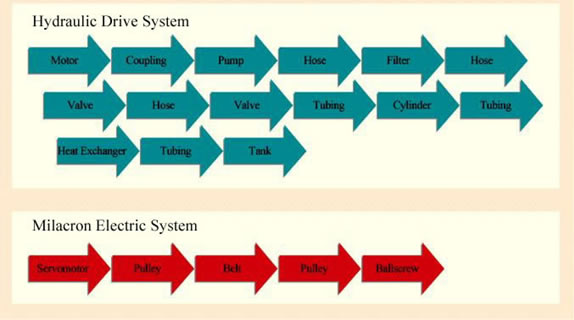

Unlike traditional hydraulic injection molding machines, which use energy even while idle, all-electric injection molding machines consume energy only when required for a given action, and motor output is matched to load requirements.

Instead of being driven by a hydraulic system, all-electric machines use digitally controlled, high speed and highly efficient servo motors to drive the whole process. Each axis is controlled by an independent motor for injection, extruder, clamping and ejection.

The result is a faster, cleaner, more repeatable and energy efficient injection molding process. Energy consumption for an all-electric machine can be reduced by 50 to 75% over that for a hydraulic machine. It’s no surprise, then, that all-electric injection molding machines now make up over half the injection molding machines sold annually in the United States.