100% Recyclable PET Vies to Replace Composite Cans

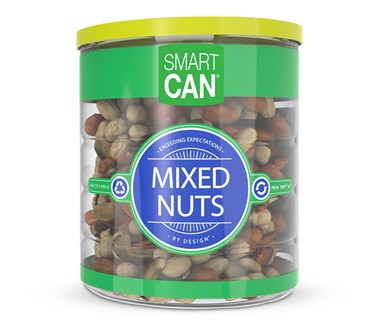

Ring Container Technologies, Oakland, Tenn., a blow molder of HDPE and PET packaging, announced the first customer for its new SmartCAN, a PET can designed to replace the common composite can with a much more easily recyclable alternative at comparable cost.

Ring Container Technologies, Oakland, Tenn., a blow molder of HDPE and PET packaging, announced the first customer for its new SmartCAN, a PET can designed to replace the common composite can with a much more easily recyclable alternative at comparable cost. John B. Sanfilippo & Son, Inc. (JBSS), Elgin, Ill., whose brands include Fisher Nuts and Orchard Valley Harvest, has chosen SmartCAN for its dry snacks. The all-PET container replaces a composite can composed of paperboard with an aluminum foil interior facing and two metal ends.

SmartCAN is made by two-stage stretch-blow molding, with a dome on top that is trimmed off, a technique Ring Container has used on other products as a cost-effective means of making a wide-mouth container. The can is topped by a peel-off lidding foil (applied by the customer after filling) and by a snap-on HDPE lid (a screw-on version is available). The customer also provides the wrap-around label. The can has a slightly domed bottom, which provides stability during conveying. The can is designed to resist “paneling” deformation if filled with a warm product, says Cory VanLoocke, director of sales & business development. He also notes that SmartCAN is 35% lighter overall than a composite can of the same size (38.5 g vs. 59 g).

Ring Container Technologies previously supplied JBSS for years with PET wide-mouth jars as snack containers, but SmartCAN is the company’s first “drop-in” replacement for composite cans, that’s adapted to existing filling lines. As noted by Tim Ferrel, v.p. of business development, SmartCAN addresses consumers’ and brand owners’ growing interest in recyclability and it also has the advantage of transparency, allowing the consumer to view the package contents. SmartCAN is currently available in two standard sizes—401 x 411 and 401 x 406 (30.5 and 28.6 fl oz, respectively)—though others will be available in future. What’s more, the PET can is customizable both in size and shape—“It doesn’t have to be a simple cylinder, unlike a composite can,” says Ferrel.

Ferrel sees numerous opportunities for SmartCAN beyond dry snacks, such as dried fruits and instant foods. Though the can is currently produced at two locations, it could in future be made at any of the company’s 19 “focused plants” in the U.S., Canada and U.K. It does not require special production machinery, only tooling.

VanLoocke adds that the PET can could potentially incorporate up to 50% post-consumer recycle (PCR), enhancing its environmental advantages. He notes that a lifecycle analysis (LCA) performed by an independent third party (using the COMPASS LCA software tool) shows that SmartCAN produces 42% less greenhouse gas emissions using virgin PET, and 50% less with addition of 30% PCR, than a composite can of the same size.

VanLoocke and Ferrel both note that the company is committed to sustainability throughout its operations and just this year joined the How2Recycle program of the Sustainable Packaging Coalition, becoming the 200th member of this North American group. As a result, Ring Container labels will now contain instructions for consumers on how to prepare the empty package for recycling (such as inserting the lid or rinsing the container); identify the types of materials used and which parts are recyclable; and inform consumers whether those materials are recycled widely or in limited capacity.

Related Content

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreBlow Molder with a Mission: CKS Packaging Shares Gains Of Its Phenomenal Growth

From three machines in 1986 to 27 plants nationwide today, this family-owned processor has prospered through unwavering customer service, committed employees and dedicated service to its community.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More