‘First’ Carbon Fiber Smartphone Developed by German Startup

Lanxess Tepex dynalite 208 TPU is the matrix material for Carbon Mobile’s ultra-thin and extremely light smartphone.

What is said to be the ‘first’ carbon fiber smartphone that sets new standards for lightness, slim design and sustainability made its debut this March, from Berlin-based startup Carbon Mobile. “Designed and engineered in Germany, the Carbon 1 MK II reignites miniaturization and drives sustainability in connected devices by replacing plastics and aluminum with advanced composite materials for the first time,” says Carbon Mobile’s CEO Firas Khalifeh.

The base material for the production of the housing is a thermoplastic composite from Pittsburgh-based Lanxess’s Tepex dynalite portfolio, specifically Tepex dynalite 208 TPU. It is reinforced with fabrics of incredibly fine 1K continuous carbon fiber filaments. Explained Philipp Genders, Tepex expert in application development at Lanxess. “Our composite material, which we developed for extremely lightweight components subjected to considerable mechanical stress, does more than just allow exceptionally thin wall thicknesses. In fact, with its high degree of strength and rigidity, it also helps to make the housing very robust for day-to-day use,” “In addition, the matte-black carbon-fibers give the smartphone a truly high-tech look.”

Despite their advanced properties for producing robust yet lightweight structures, carbon fibers behave in an electromagnetic shielding manner. This means that they block radio signals, forming a Faraday cage that rather than allowing signals to pass through, instead disperses them around the outer body of the device. Connected devices with carbon fiber, for this reason have been viewed as an impossibility by the tech industry.

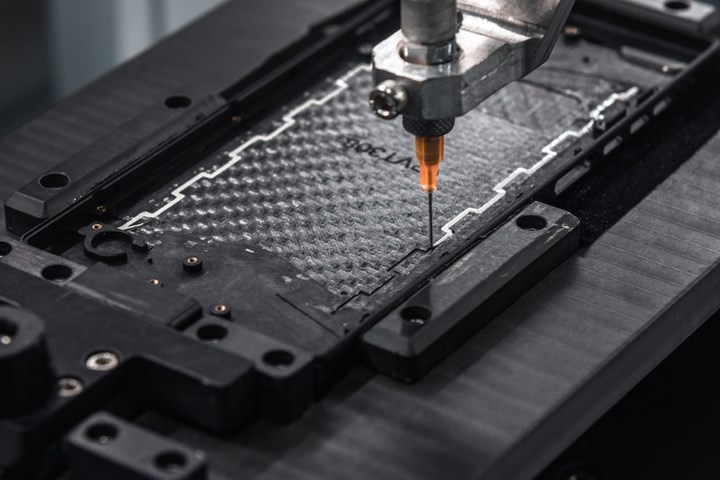

After four years of research and development, Carbon Mobile’s engineers have developed a revolutionary process to unlock carbon fiber’s potential for connected devices. The patented HyRecm (Hybrid Radio Enabled Composite Material) technology fuses carbon fibers together with a complementary composite material capable of RF signal permeation. To further boost the devices connectivity, a unique 3D-printed conductive ink is integrated into the carbon fiber structure. The result is the first “radio enabled” carbon fiber based material.

Applied for the first time in the Carbon 1 MK II, the new technology produces a robust carbon fiber-based housing structure that is not only incredibly thin and light, but also made from less than 5% plastic. Said Eric Chan from processing partner Modern Composites Ltd., “Lanxess and their Tepex materials made the perfect partner in the development of HyRecm Technology. Being able to work with a superior material from Germany ensures the best application possible of this revolutionary technology from launch.”

Following the same construction principle as the load-bearing chassis of a Formula 1 car, the housing is designed as a monocoque, or “single shell”. As a result, it makes optimized use of the extreme rigidity of carbon fiber reinforced plastic (CFRP). This contributes significantly to the thin wall thicknesses and low weight of the smartphone and also enables miniaturization. That is because there is no bulky reinforcement taking up space on the inside of the housing. According to Khalifeh, ”Our cutting-edge monocoque design enables a device that weighs only 125 grams, a third lighter than conventional smartphones. At just 6.3 millimeters, it is also 25% thinner as well.”

Working toward a world with less electronic waste, Carbon Mobile is committed to sustainable principles. The new smartphone uses only recyclable materials wherever possible. Said Khalifeh,“We want to deliver our contribution to cutting electronic waste and improving sustainability around the world,” says Khalifeh. The composite material used for the housing can also easily be recycled and repurposed for new uses. Added Genders, “Like all products in the Tepex dynalite product line, it can be shredded and then processed on standard injection-molding machines to make high-quality components, either by itself or mixed with suitable new material.” To extend the service life of the smartphone, all its components are designed to be easily replaceable for repair purpose, which also prevents the creation of electronic waste.

Related Content

K 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreRiverdale Global Showing Latest Innovations and New Satellite Location in Wisconsin

NPE2024: Live demos of updated RGS controller are among the highlights at its Wisconsin facility that will house the ‘new’ color R&D lab.

Read MoreAdditives Boast Sustainability Without Sacrificing Performance

Sustainability continues to dominate new additives technology, but upping performance is also evident. Most of the new additives have been targeted to commodity resins and particularly polyolefins.

Read MoreCompatibilizer for Nylon/ABS Alloys

CAI Performance Additives’ ST-AN3230 has shown to improve both compatibility and performance of nylon/ABS alloys.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More