LG Chem to Build Fourth Carbon Nanotube Plant

This plant will be equipped with world’s largest single-line carbon nanotube (CNT) production.

South Korea’s petrochemicals and advanced materials producer LG Chem is expanding its investment in carbon nanotubes (CNT) with theconstruction of the world’s largest single-line CNT manufacturing unit. The new plant is part of LG Chem’s initiative to gain a more competitive edge in the rapidly growing global CNT market focused on electric vehicle (EV) battery materials.

The new facility will be LG Chem’s fourth CNT plant, following Plant 3 which started construction early this year and Plant 2 which has been operational since last year. The new plant will be built in LG Chem’s Daesan Complex, located 49 miles southwest of Seoul, with construction commencing in the first half of next year and operation beginning in the second half of 2024. CNTs produced by LG Chem will be supplied as conductive additives to battery makers such as LG Energy Solution, the current leader in the global EV battery market, with plans for usage to be expanded to a broader range of industries.

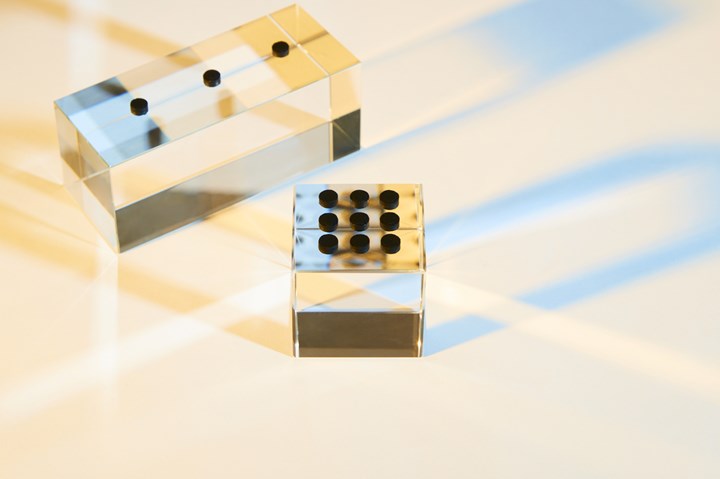

A next-generation material, CNT has been shown to offer the equivalent level of electricity and thermal conductivity as copper and diamond and 100 times the strength of steel. Due to its excellent properties that surpass existing materials, CNT has an infinite range of applications in batteries, semiconductor wafer trays, automotive components, and surface heating elements. The global CNT conductive additive market is expected to grow by 30% to $2.3 billion contributing to the demand of CNT increasing from 11 million/lbs in 2021 to 154 million/lb by 2030.

https://www.lgchem.com/The 7 million/lbs of CNT produced at Plant 4 will contribute to LG Chem’s total carbon nanotube production capacity of 13.4 million/lbs across four plants. LG Chem has been operating CNT plants since2017, starting with 1.1 million/lbs production at its CNT Plant 1, and has been building new plants every year since 2020 to meet growing demand. Thanks to the company’s fluidized bed reactor technology, each production line at all four CNT plants can produce up to 1.3 million lb/yr, the highest single-line capacity in the world.

The CNTs produced at the plants reportedly are also high-quality as LG Chem’s self-developed cobalt-based catalysts help lower magnetic impurities which may negatively affect battery quality. Production capacity per capita at LG Chem’s Plant 4 is expected to be 20% higher than its other plants due to efficiencies related to improved reactor stability and process automation. When utilized as a conductive additive, CNT demonstrates 10% more conductivity than carbon black, allowing battery makers to use 30% less conductive additives. The available space can then be filled with cathodes for higher capacity and longer lifespan without increasing the overall size of the battery. Given this, CNTs are also being considered attractive futuristic conductive additives for even anodes and next-generation batteries such as lithium-sulfur and solid-state batteries.

Related Content

-

Process Aid Concentrates are PFAS-Free

Wide range of products for cast/blown film and pipe.

-

Graphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

-

Masterbatches Reduce Gloss in PLA and PETG 3D Printed Products

Insight Polymers & Compounding’s two low-gloss additive masterbatches shown to boost appearance of 3D printed objects.