Licensee of EconCore's Thermoplastic Honeycomb Technology Gets Two New Automotive Contracts

Mexico’s Fynotej secures two major contracts to supply automotive trunk load floors using Fynocore continuous honeycomb panel technology licensed from EconCore

The thermoplastic honeycomb technology of Belgium’s EconCore is now being introduced into two of the world’s largest automotive manufacturers by Fynotej. Based in Mexico City the company is considered a leader in the manufacturing of non-woven products, as well as in the manufacturing of panels with honeycomb core technology for several industries including automotive, packaging and construction.

The Mexican company has secured two major contracts to supply 120,000m2 of trunk load floors over two years using Fynocore—one of which is for a completely new, not-yet-launched project and the other is for a current, already-in-production platform. Fynocore is the brand name for Fynotej’s continuous honeycomb panel technology, licensed from EconCore. It has been shown to provide many advantages over existing, conventional solutions. The product is extremely lightweight yet offers incredible strength and as an overall process delivers value for money against conventional solutions. Its lightweight properties can contribute to greater fuel savings and a reduction in CO2. In addition, the product is typically made from 30% recycled content, making it a more sustainable and environmentally friendly product.

Said EconCore COO Tomasz Czarnecki,“The ability to continuously ‘extrude’ honeycomb sandwich panels cost effectively, combined with the perspective to choose out of many material choices for both, core and the skins, provides great optimization potential and opens up countless applications that the technology is being used for.”

In this automotive application, the honeycomb core panel is made from PP, which is lighter and better performing than the conventional, more expensive solutions. Fynotej also use a proprietary inline lamination process that can laminate panels with non-woven automotive carpets by thermofusion without using adhesives. This can result in further savings to customers.

Said Fynotej’s sales manager Fabiola Carbajal, “We’re excited about the range of applications the honeycomb technology can be used for, with its excellent lightweight and strength characteristics. It is extremely versatile as it can be tuned to fit customer’s requirements while, for the applications requiring it, the thermoplastic honeycomb panels can also be effectively compression molded to more complex geometries. We’re keen to engage with automotive OEMs and tier one suppliers, ideally in the design stage, where our products can be specified from the outset. We know vehicle manufacturers, as they transition to electric and hybrid cars, see light-weighting as a critical area for development, to increase the range of these vehicles. Our products fit very well with this thinking, as well as being commercially competitive too.”

Fynotej believe they have a superior, cost efficient product that outperforms conventional solutions. At the same time the technology fits ideally into the market trends with regards to sustainability, offering an easily recyclable lightweight product based on minimal amount of thermoplastic material, where this thermoplastic material creating the honeycomb panel is often already recycled.

Added EconCore’s Czarnecki,“What Fynotej are doing with the technology today, not just in the automotive sector, but also in packaging and construction, is a perfect demonstration of the sheer versatility of the technology. We’ll continue to support Fynotej as a licensee, by pushing the technology developments further and exchanging the know-how.”

Related Content

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreRead Next

EconCore Expands Continuous Production of Thermoplastic Honeycombs for Composites

ThermHex technology has been used successfully to produce honeycombs from several high-performance thermoplastics.

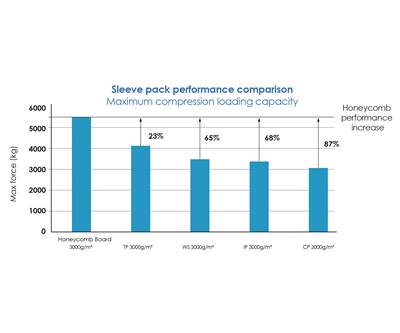

Read MoreHoneycomb Core Sleeve Packs Set New Performance Standard

Sleeve packs produced with EconCore’s ThermHex technology outperform alternatives in container box compression tests.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More