Harmonization of Injection Molding Safety—PLASTICS’ Perspective

Stan Glover, U.S. TAG Chairman for the development of the new ISO injection molding machine standard, shares his views on the new global guideline seven years in the making.

Safety standards for plastics and rubber machinery have long been the purview of national or regional groups, belying the increasingly international nature of the plastics processing industry. A company with plants in Ohio, Mexico and China could expect different safety standards for its equipment in those disparate facilities and regions.

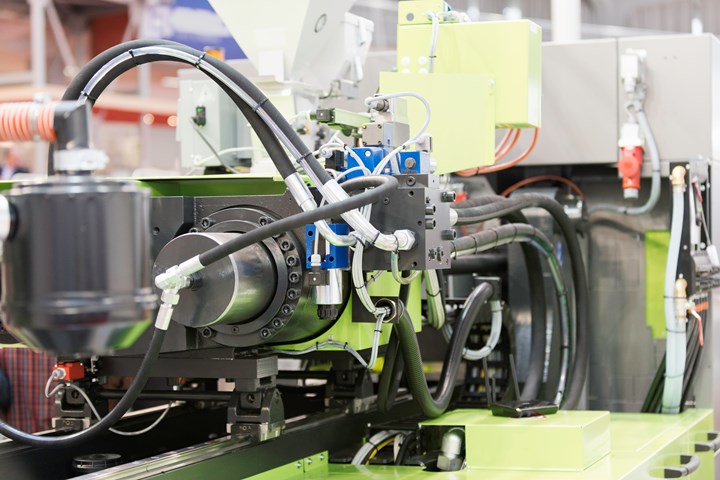

The new international ISO standard— ISO 20430:2020—is a first, and it only came after seven years of collaboration from 40 experts contributing from 13 different countries. At the table for the U.S. was Stan Glover, director of technical sales for Zeiger Industries by day, so to speak, and U.S. TAG chairman representing the Plastics Industry Association (PLASTICS) as it sought to guide and direct the standard’s creation.

Glover told Plastics Technology that PLASTICS’ involvement in the development of the final document was ongoing and purpose driven. “PLASTICS involvement was strategic in that it was focused on prevention of additional layers of regulatory burden on the users,” Glover said. “Our member contributions to the process helped to avoid conflict between the existing American National standard and the resulting ISO document. This allows manufacturers to move easily between marketplaces while maintaining compliance.”

The length of the creation process—7 years—was not a result of fundamental disagreement among the contributors, according to Glover, and the extra time ultimately contributed to a better final product. “The eventual ISO standard took an unusually long time to develop not because there was any real lack of consensus amongst the national member experts developing the document but primarily because of the CEN consultant review process necessary in order to produce a ‘harmonized’ standard for the European Union—one that can be adopted in their EU Official Journal—added several years to the development,” Glover said. “However, even that had a positive aspect inasmuch as it—among several other similar incidents—caused a critical review and improvement of that consultant review process.”

To create the standard, a mix of existing U.S. and European guidance was used: EN 201, which served as a template, and ANSI/PLASTICS B151.1-2017. “The ANSI/PLASTICS standard had a significant influence on the overall development of the ISO standard,” Glover sad, “and both standards are reasonably well harmonized with each other in terms of their respective requirements.”

Glover noted that both the ISO and ANSI standards present a detailed discussion on the various types of hazards in different areas around the injection molding machine and include a thorough presentation of risk reduction measures that might be taken to deal with those hazards. In addition, both the EN and ANSI/PLASTICS standards include extensive annexes on additional relevant topics.

In terms of differences, Glover explained that the really significant variance between the two standards is that the B151.1 document includes user requirements—“This is a ‘must’ for the North American market,” Glover said—whereas the ISO standard does not. “That is primarily because of the EU Machinery Directive, which places the entire onus of a so-called ‘safe machine’ on the manufacturer,” Glover explained. In addition, there is also some guidance in the ANSI standard on how to deal with existing injection molding machines, while the ISO standard is silent on that front, only addressing machines built after April 2020.

Glover said that moving forward PLASTICS is also actively participating in the ISO TC 270 WG 3 committee, which is working on Magnetic Mold Clamping System Safety, and it will also be chairing WG 2 – Safety of Extruders once Covid-19 concerns wane.

ISO 20430:2020 was seven years in the making with input from 40 experts hailing from 13 countries.

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreNPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreRead Next

Newly Formed Global Plastics Alliance To Harmonize Recycling Testing

North American and European associations seek a coordinated industry voice to create a Global Plastics Protocol.

Read MoreNew Global Standard Aims to Harmonize Injection Molding Machine Safety

ISO 20430—the first international safety standard for plastics and rubber machinery—was published after more than seven years of collaboration by roughly 40 experts from machine makers, associations, and health and safety organizations hailing from 13 countries.

Read More