Self-Driving Shuttle Built on Giant 3D Printer

LM Industries builds eight-person shuttle vehicle on 40-ft printer.

Local Motors in Phoenix, Ariz., creator of the world’s first 3D-printed car, the Strati, was combined last year with the Launch Forth collaborative design community into LM Industries, based in San Francisco. LM Industries calls itself the world’s first digital OEM, which can take concepts to deployed products in under one year. It brings products to market in an entirely new way, designing with its global community of experts, and applying technology such as 3D printing to create and assemble products in small batches at agile microfactories. LM Industries creates transportation, accessibility and mobility products with customers such as Allianz Group, Airbus and the United States Marine Corps. Its efficiency allows products to be upgradeable like software—iterated regularly and fluidly to match rapidly changing consumer preferences.

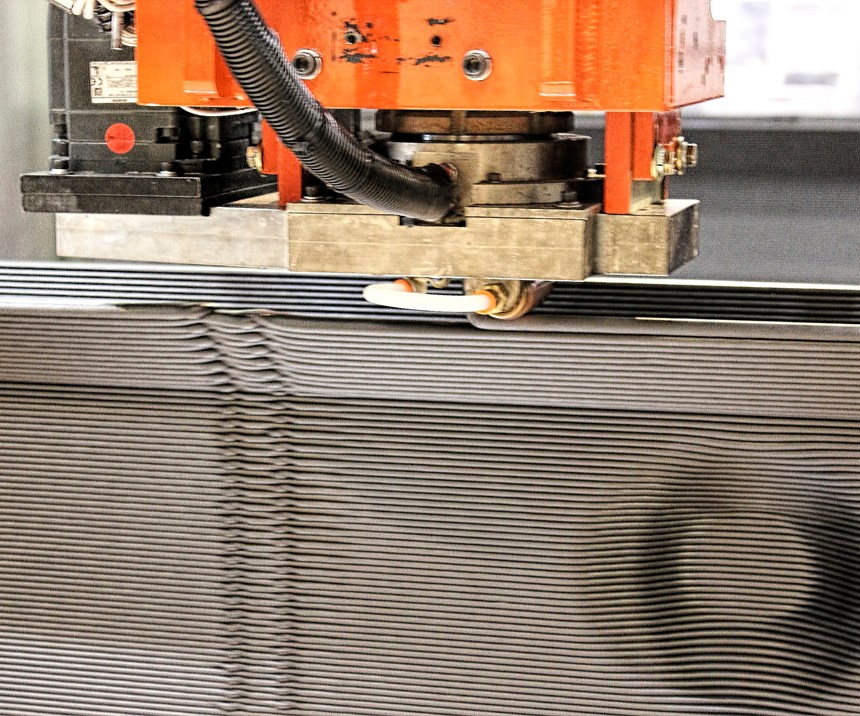

One concept that continues to gain momentum is the company’s small autonomous shuttle vehicle named Olli. Created in 2016 by Local Motors, Olli is a 3D-printed, self-driving “smart shuttle,” offered as a sustainable transportation option for cities, hospitals, campuses, entertainment districts, etc. LM Industries sees carbon fiber as a core component of the future of additive manufacturing and it’s essential to the Olli, which is built from carbon-fiber reinforced thermoplastics.

Thermwood, Dale, Ind., installed the Large Scale Additive Manufacturing (LSAM) system to produce Olli at Local Motors’ facility in Knoxville, Tenn. With a build envelope of 10 x 40 ft, it’s said to be the world’s largest composite 3D printer. Thermwood says LSAM machines can be up to 100 ft long. They can print both horizontally and vertically and both print and trim on the same machine.

Since Olli is custom designed and 3D printed, different features can be added so that a new shuttle can be designed and printed to fit a city and campuses. Local Motors can simply change the file and a print a batch of Ollis that fit a customer’s needs. In early August, Olli was deployed at the State University of New York (SUNY) at Buffalo as part of a partnership with the school and New York State. The shuttle is being used on campus for mapping, autonomous education and testing potential transportation options. LM Industries is inviting municipalities, campuses and designated districts to propose a short-term, local use for Olli. One location will be selected to receive a fleet of eight-person Olli shuttles to use for about three months. This is the second of the company’s so-called “Fleet Challenges,” more of which are planned.

Related Content

-

Injection Molded Tape and Resin “Sandwich” Technology Debuts

During its Mobility Days in Austria, Engel and KTM Technologies debuted an all-plastic molded motorcycle seat base produced via a tape-sandwich process that can run in a standard molding process.

-

Plastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

-

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.