Thermoforming Made More Effective with Industry 4.0

Illig’s new Illig Assist digital service platform to actively support thermoforming customers on the way to Industry 4.0

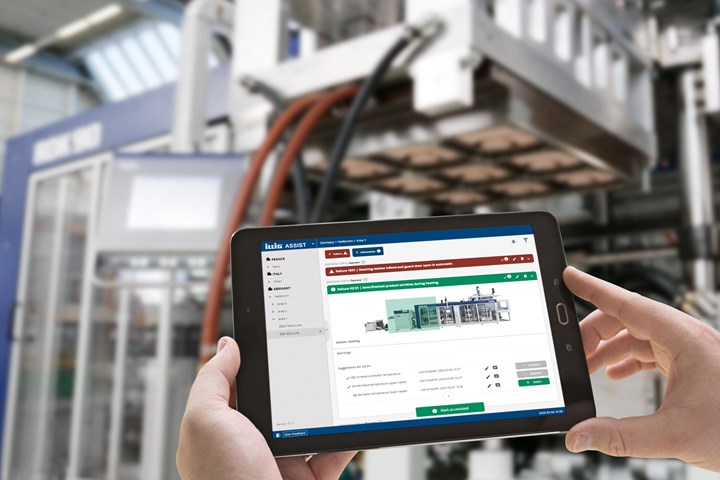

A new digital service platform, dubbed Illig Assist, designed to actively support its thermoforming customers on the way to Industry 4.0 has been launched by Illig Maschinenbau. Digital transformation is increasingly becoming a reality thanks to breakthrough technologies, and this also applies to the packaging industry.

Illig systems have long been equipped with the Intelligent Control Concept (Illig IC), including calculation of machine parameters, a guided setup systems, and dynamic optimization. In addition, thermoforming systems can connect to local networks and databases to query production-related data. The new Illig Assist complements these digital systems and helps the machine operator as a learning component to cope with occurring events in the daily workflow. In the past, companies relied on notes and the “tribal knowledge” of experienced individuals. The new application simplifies knowledge transfer through a clear and interactive graphic user interface.

Messages from both connected machines and machine operators themselves are recorded and displayed chronologically. The system automatically provides a visual localization of events and offers detailed suggestions based on a solution database, initially populated by Illig’s expansive global expertise. Moreover, operators can actively contribute their own suggestions and enrich them with videos and images. An integrated comment function allows users to comment on and evaluate proposed solutions. Users can also view and manage shift reports, maintenance information, and digital manuals. This approach reportedly serves to build up a permanent knowledge database, prevents the loss of knowledge due to the departure of experienced machine operators, and accelerates training for new employees.

Illig Assist is based on the IIoT platform Adamos and is expandable through a modular architecture of microservices that enable connections to external systems. Events reported to Illig Assist can be displayed using any internet-enabled communication terminal and operators can be remotely informed. Event notifications are made by the operator or, in future versions, directly by the machine in the case of networked machines connected to the IIoT platform. Messages are automatically made available to other approved users inside the organization.

In addition to asset management and chat function per machine, Illig Assist also provides rights management for creating and reading comments and other information. Depending on the user’s rights, the system offers insight into the machine with its functional sub-blocks as well as an overview of the entire line, factory, or worldwide locations.

Related Content

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Adding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

-

Equipment Suppliers Show Adaptability and Smarts at TaipeiPlas 2024

Customizable equipment solutions, warm hand-off support, and seamless software integrations highlight Taiwan’s plastics show.