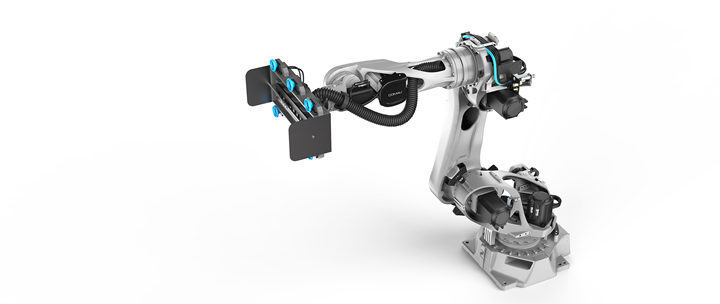

6-Axis Robot Line Launched

Available globally, Italian supplier Comau’s N-220 line of articulating-arm robots has a 220-kg payload.

Italian robotics supplier Comau (Turin) is introducing the first of a new generation of 6-axis articulated robots—the N-220—saying the systems are available now on a global basis (the company maintains three offices in Michigan). Comau says the N-220 industrial robot features a modular constructure with fewer total components, advanced motors and APC drivers.

Featuring a wide working area and high payload of 220 kg, the N-220 robot has a hollow forearm and direct kinematics, with absolute calibration and motion algorithms. It also comes fitted with integrated forklift adapters and optional high-torque washers for automatic anchoring base fixing, easier relocation and faster installation.

Comau says its e-Motion software algorithm can improve cycle time, motion quality and path control. A nitrogen balancing system on axis 2, and larger stroke-ends on axis 3, give the N-220 greater agility and a wide backward working area that is ideal for bending and handling applications. The N-220 uses only two motor sizes, and a single oil type, making repairs easier.

The robot applies Nodal speech-based coding language for open, easy programming, and it has two separate, flexible harnesses for robot and application power supply.

Comau’s N-220-2.7 6-axis articulating-arm robot is available globally.

Photo Credit: Comau

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.