Higher Stretch-Blow Productivity for PET and HDPE

NPE2024: Aoki debuts higher output, single-stage ISBM presses and a lightweight packer bottle in HDPE.

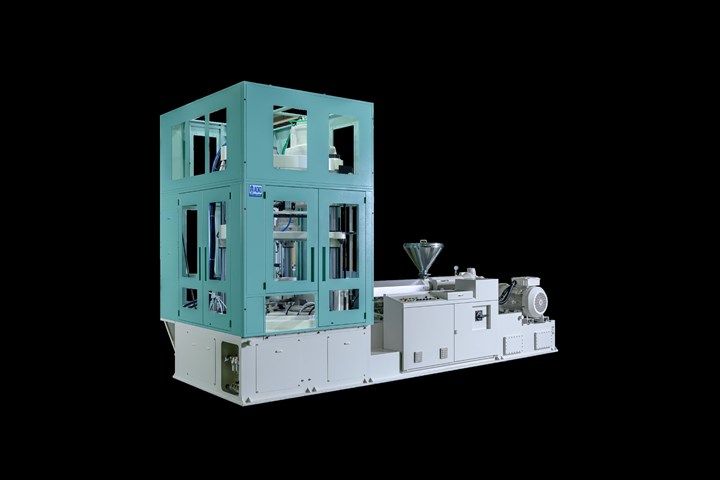

New AL-500LL-60S is now Aoki’s standard model, superseding the AL-500LL-50S. It is molding both 1 L PET round jars and 225-ml HDPE packer bottles at the show. Source: Aoki Technical Laboratory

In four operating machine exhibits, Aoki Technical Laboratory is highlighting productivity improvements in single-stage stretch-blow molding for narrow- and wide-neck PET containers, as well as a lightweight bottle design for popular HDPE pill packers.

First, Aoki is introducing its new standard model with even greater performance than its previous flagship model AL-500LL-50S. The new AL-500LL-60S is molding 125-ml cylinder bottles in PET at 5,400 bph.

A second exhibit features the same machine producing a lightweight bottle that Aoki developed for the increasingly popular HDPE packer market. It’s molding 225-ml bottles at 2,200 bph.

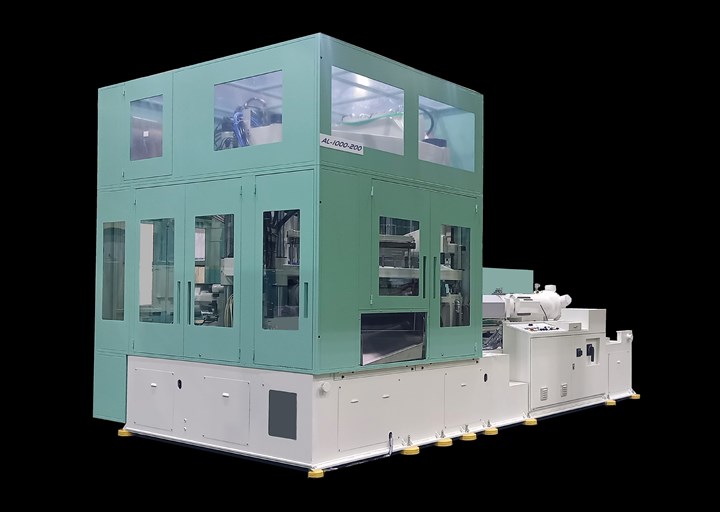

Aoki simplified its AT-1000NL-300 two-row machine to a single row in the new AL-1000-200 pictured here. This enables the new machine to mold products with a body diameter exceeding 100 mm and up to four cavities with a neck diameter of 120 mm or more. Source: Aoki Technical Laboratory

Third, Aoki changed the structure of its AL-1000NL-300 two-row machine to a simpler one-row design that enables this AL-1000-200 model to mold containers with a body diameter exceeding 100 mm. The previous model could not mold more than two cavities with a neck diameter of 120 mm or more, but the new version can mold up to four cavities with that neck diameter, depending on product size. At the show, it’s producing 1 L PET round jars at 2,800 bph.

Aoki’s AL-1000-60 is making its debut at a global trade show. This single-row model has a 34% shorter dry cycle, twice the overall productivity and 36% faster mold change than the earlier two-row AL-500N-60. Source: Aoki Technical Laboratory

Another single-row machine is making its debut at a global trade show. The AL-1000-60 can mold up to 20 containers; its dry cycle is 34% shorter than Aoki’s earlier two-row AL-500N-60; and the simpler mechanism enables mold-change time to be cut by 36%. Moreover, the company’s latest high-speed molding technology is said to enable a single machine to deliver the same productivity as two of the earlier models. The new version is molding 100-ml round PET bottles at 10,900 bph.

Related Content

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.