Monofilament/Tubing Line Features New Water Bath, Winder

Shorter water bath, modular winders make system more flexible.

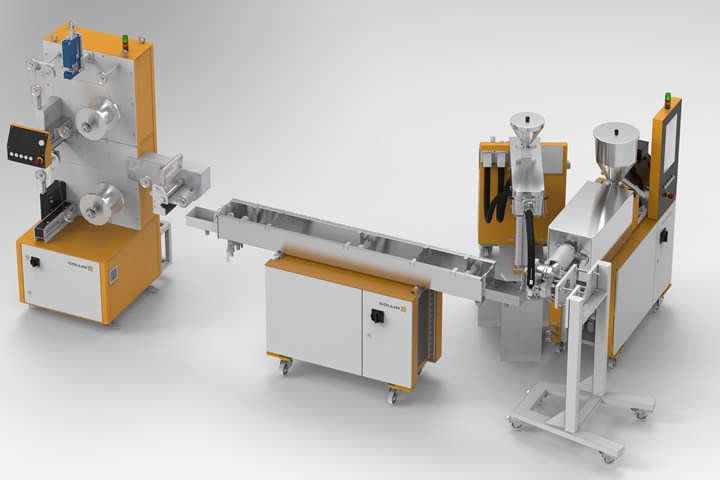

During October’s Fakuma in Friedrichshafen, Germany, Collin displayed its compact lab-sized 3D-filament line with a new winder and a new, shorter water bath.

The new water bath is available in different configuration levels and is equipped with an optional tempering. The water baths are available in different lengths to guide the strand horizontally and vertically. In order to increase the flexibility for different procedures, several water baths can be arranged successively.

Due to the modular design, the line, which can also be used to make strands and tubing, different machine components can be switched depending on customer requirements. The new, modular filament winder is said to be especially suited for round strands or small tubes. The strand runs via a filament guide, then via a dancer system. The winding unit has one or two winding positions; two can sequentially or be operated in parallel. For additional winding positions, several filament winders can simply be coupled.

Related Content

-

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

-

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

-

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.