New Dual-Head Accumulator Machines and Electric Clamp Options

NPE2024: ST Blowmoulding highlights new dual-head accumulator machines, energy-saving electric clamps and other innovations.

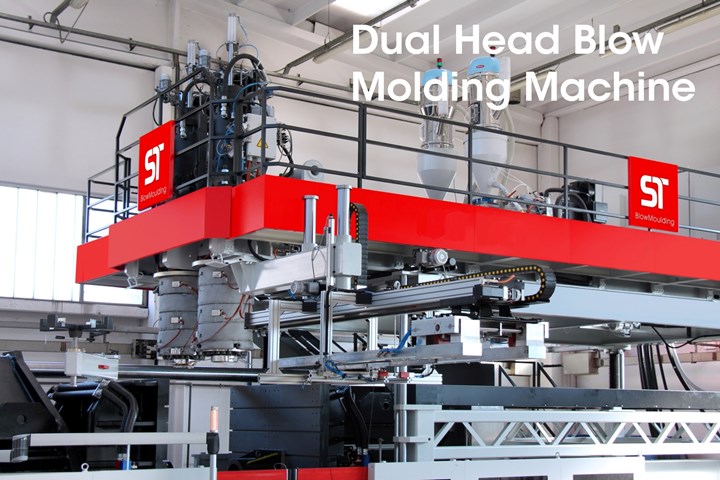

New dual-head accumulator machines from ST Blowmoulding are available with optional electric clamping systems. Source: ST Blowmoulding SA

Industrial blow molding machine specialist ST Blowmoulding of Italy is showcasing its latest developments in accumulator-head and continuous-extrusion technologies. At center stage is its new line of dual-head accumulator machines with new controls, optimized material usage and what are said to be “the lowest energy consumption in the market and the highest possible OEE (Overall Equipment Efficiency).” The upper platform of a dual-head machine will be on display (photo).

Also new are energy-saving electric clamping units (introduced at K 2022), optional on dual-head and other machines. These are paired with the company’s adiabatic extruders for high energy efficiency. The company says its large machines exceed the top level of energy efficiency under Euromap 46.1: class 10 or <0.13 kWh/lb of material processed.

In continuous-extrusion technology, ST Blowmoulding is presenting new concepts for high-output molding of L-ring drums and IBCs. The company also offers multilayer technologies for both continuous-extrusion and accumulator-head machines. For accumulators, a new design of the flow channels is said to significantly improve the balance of the layers, suitable for two or three layers, as well as the ability to provide an additional outer coating layer with a separate accumulator chamber.

Other focuses of its display include foaming technology for material savings; the company’s work on hydrogen liners for composite pressure vessels; and suction blow molding for automotive applications such as coolant lines of EVs.

Related Content

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

-

Impacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

-

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.