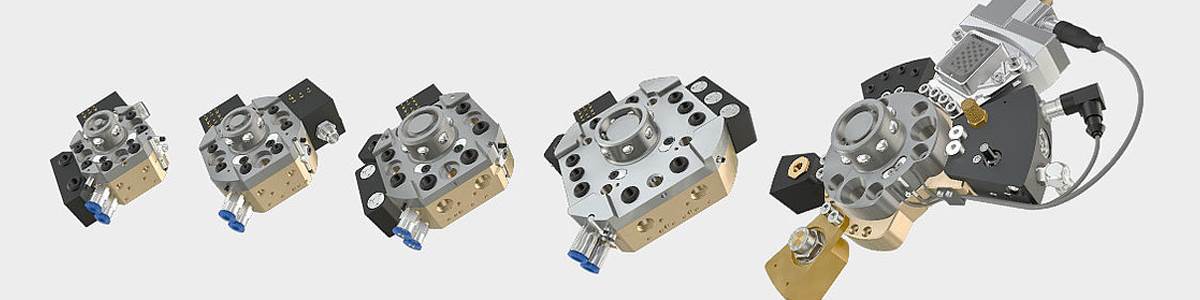

Stäubli Connectors’ newly designed MPS range of compact robotic tool-changing systems offers five new sizes covering a payload range up to 176 lb (80 kg). The company says the line accommodates a variety of transfer technologies with precise repeat accuracy of ±1.5 µm.

The full range—MPS015, MPS025, MPS035, MPS055, and MPS080—is based on a modular concept with three options to create an optimized tool-changing system. MPS Complete is a pre-configured total system that’s ready for immediate use with the shortest delivery time. MPS Modular includes an individually assembled product with customer-requested features that’s ready for immediate use and can be delivered on short notice. MPS Customized systems are specifically tailored to the customer’s application requirements.

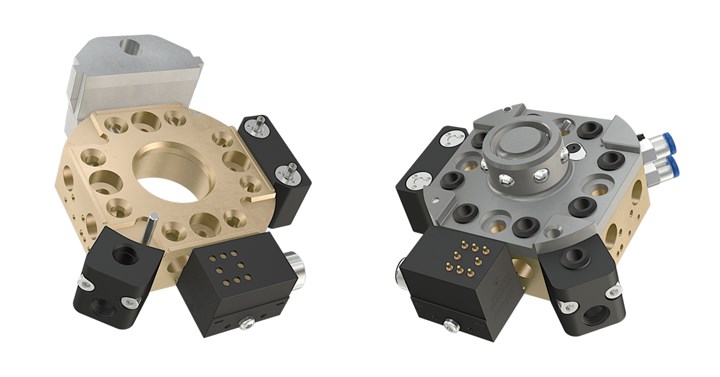

Feed-throughs for pneumatics or vacuum are integrated into the locking units of these new systems. To support expansion flexibly, numerous additional modules are available for the transmission of pneumatics and vacuum; signal and data transmission; or for shielding, grounding, tool coding, and data storage.

The robot side of the MPS tool changer is equipped with all the necessary modules to be able to use the tools relevant for the robot. On the tool side, only transmission modules required for operation of the tool are needed. This makes it possible to operate up to six differently equipped tool sides with one robot side.

For the connection between the MPS’ robot and the tool side, Stäubli combines cross-shaped guiding surfaces with a spring-loaded ball-locking system. The tools are always brought back to their precise insertion position, with repeat accuracy of ±1.5 µm.

Staübli’s MPS is based on a modular concept with three options to create an optimized tool-changing system.

Related Content

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

Five Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.