Novel Flexible and Toughened Engineering Resin

Toray leverages proprietary nanoalloy technology to create a unique flexible and toughened type of nylon.

Japan’s Toray (U.S. office in New York City) has leveraged its proprietary nanoalloy technology to create a novel flexible and toughened engineering resin. The new polymer is said to retain the outstanding thermal resistance, rigidity, and strength of nylon 6 while delivering a bending fatigue limit that is 15-fold that of conventional polymers. Prospective applications for such exceptional durability include automobiles, home appliances, and sporting goods. Toray is looking to initiate full-fledged sample work through this year while cultivating applications in diverse industrial materials fields.

Nylon 6, whose diverse uses include automobile engine compartments and appliance housings, incorporates a flexible elastomer to resist fatigue and optimize the lifespan. However, the tradeoff is that this lowers nylon 6’s thermal resistance, rigidity, and strength. The challenge for many years has thus been to develop a new material that offers all of these desirable properties.

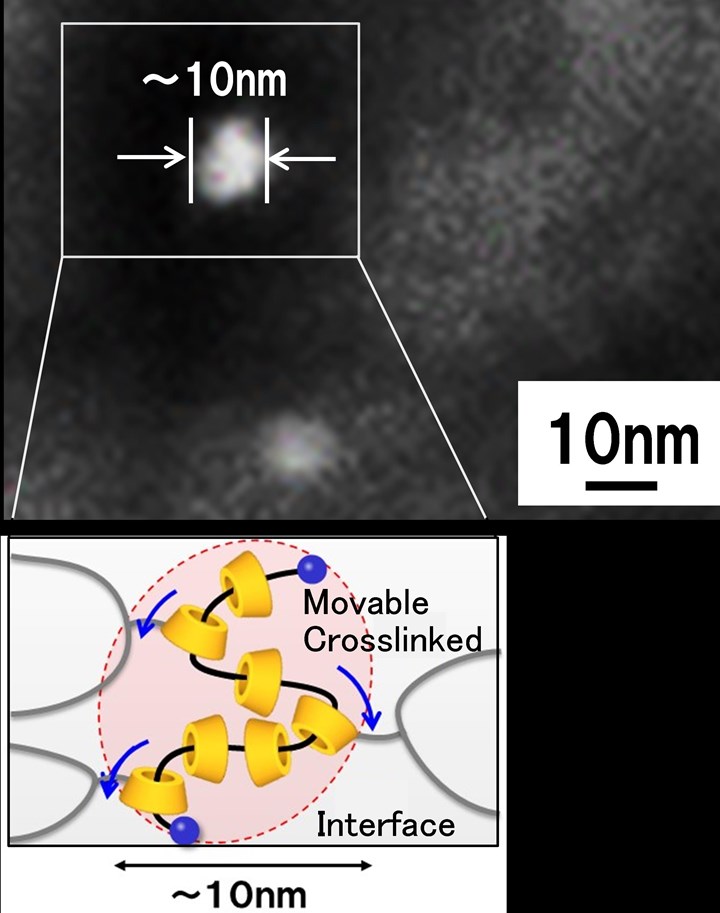

Toray focused on polyrotaxane, which has a sliding molecular bond, as a polymer whose structure moves in response to external forces. (This is a supramolecular polymer with a beaded or necklace-like structure, its molecules consisting of strings and rings). The company endeavored to balance the inherent attributes of nylon 6 and fatigue resistance by finely dispersing polyrotaxane in the resin. Toray drew on its proprietary Nanoalloy microstructure control technology to maximize the effectiveness of polyrotaxane by dispersing it in the 10 nanometer crystals of nylon 6. The resulting flexible stress-dispersion mechanism led to the creation of the new polymer.

Tests at the SPring-8 synchrotron radiation facility in Japan confirmed that the new polymer suppresses changes in the crystal structure of nylon 6 when subjected to external forces. SPring-8 Synchrotron radiation is the electromagnetic radiation emitted from accelerating charged particles radially, and features high brilliance and directivity. SPring-8 in Hyogo Prefecture, Japan, conducts experiments as one of the world’s largest synchrotron radiation facilities.

Related Content

-

Tracing the History of Polymeric Materials -- Part 29: Polyurethane

This material family has unparalleled versatility, not only in terms of the forms the material can take, but in the different ways in which it can be processed.

-

Tracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

-

TPE Made with 50% PCR Derived from End-of-Life Tires

Prism Worldwide has commercialized its first TPE with this type of recycled content based on its patented technology.