Profile Die Design Software Simulates Cooling, Shrinkage

Enables use up of to 20 calibrators in the cooling system.

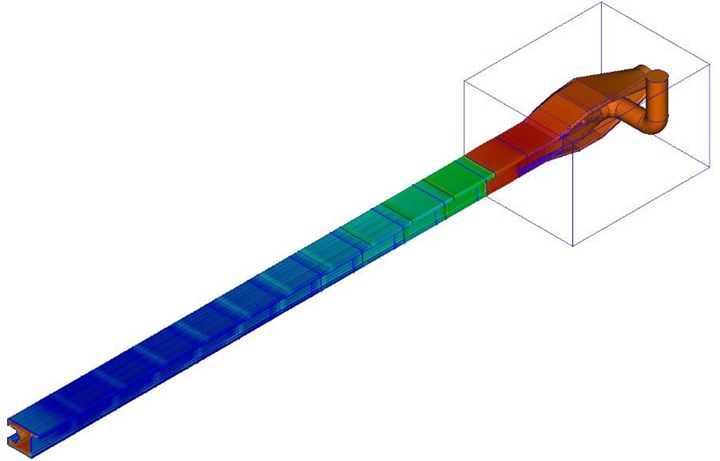

The new version of polyXtrue profile-die design software from Plastics Flow is said to accurately simulate extrudate cooling and corresponding extrudate shrinkage in the complete cooling system. It included the following features:

- Twenty calibrators and sizers in the cooling system.

- Two different temperature zones between calibrators. One of the two temperature zones can be a wiper between a water tank and the next calibrator.

- Ten different temperature zones between the die exit and the first calibrator

- Ten different temperature zones are allowed after the last calibrator.

With the software, calibrator profiles can be different from the die exit profile. By gradually changing the shape of the profile in subsequent calibrators, the shape of the extrudate profile can be significantly modified after it leaves the die, allowing extrusion of complex profiles from relatively simple die geometries.

Die geometry files can be imported from SolidWorks, Inventor and Creo software. The new version allows users to import die geometries in native Creo file format. The die geometries in SolidWorks and Inventor file formats can also be imported as before.

Related Content

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Extruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

-

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.