Robust Feeder for the Simple Stuff

Compact single-screw feeders are said to be ideal for the feeding of pellets, granules and other free-flowing bulk materials.

At the upcoming PTXPO, Coperion K-Tron will debut the ProRate PLUS, billed as a robust and reliable feeder for simple feeding applications The ProRate PLUS continuous gravimetric feeder line is billed as an economical solution and reportedly offers a quick return on investment due to its good price-performance ratio and fast delivery times.

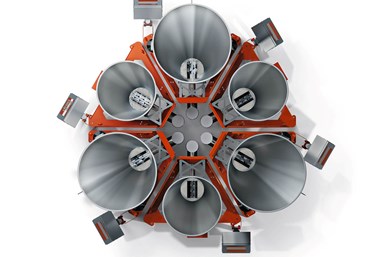

These single-screw feeders are said to be ideal for the feeding of pellets, granules and other free-flowing bulk materials in secondary plastics applications. ProRate PLUS feeders are available in three sizes and can be installed as individual units or easily arranged in cluster of up to six feeders around a process inlet, depending on the recipe formulation.

A unique design allows a very compact, space-saving arrangement. The trapezoidal shape of the ProRate Plus feeders allows up to six feeders to be easily grouped around an extruder inlet within a 5 -t radius. The three feeder models PLUS-S, PLUS-M and PLUS-L cover a wide range of throughputs. The ProRate PLUS feeders are capable of handling feed rates from 0.12 up to 400 ft3/hr, depending on the material. Theoretically a feeding system with six ProRate PLUS-L feeders can feed up to 1017 ft3/hr on a footprint of only 75 ft2.

ProRate feeders are highly standardized and include a variety of design features to optimize performance and ease of use. Simple access for cleaning and maintenance, even within a cluster, is provided thanks to a patent-pending rail system called “ProClean Rail.” ProClean Rail makes it possible to retract the base unit toward the rear of the feeder and rotate it for access to the feeding section and screw element. This allows for maintenance and cleaning of the feeding unit while keeping the feeder in position. In addition, the bellows and screw use the latest magnet technology for simple but robust mounting.

The magnet connections allow these parts to be released without tools while at the same time providing the required holding force for optimal and safe operation. Thanks to the high level of standardization of the feeders, the number of spare parts required for emergency stock is minimal. Many parts are identical for all three models and can be used as exchange parts for all devices.

ProRate PLUS feeders are suitable for use in hazardous locations rated NEC Class II, Div. 2, Group F & G and ATEX 3D/3D (outside/inside).

All ProRate PLUS feeders are equipped with P-SFT load cells, featuring reliable Smart Force Transducer weighing technology. They operate under compression and provide accurate, stable and reliable digital weight measurement under a broad range of operating conditions. The load cells supply a direct digital weighing signal and the onboard microcontroller ensures excellent repeatability and stability. P-SFT load cells have a high tolerance to vibration and electrical noise. They feature built-in over and underload protection.

Each feeder comes equipped with its own pre-wired ProRate PLUS PCM control module. The PCM is mounted to the feeder stand, with adjustable height positioning. Each PCM is pre-tested in Coperion K-Tron’s manufacturing facility prior to shipping. There are two models of PCM to choose from: a basic motor control unit (PCM-MD) or an advanced version with integrated user interface and line control functionality (PCM-KD). Within a group of up to eight feeders, one feeder must be equipped with the PCM-KD while the PCM-MD is sufficient for the others.

The PCM-KD comes with all the software the ProRate PLUS feeder will need for continuous applications and supports all three feeder models. Connection between weigh feeders, operator interface and smart I/O is via an industrial network. All motor setup, diagnostics and operator interface functions are integrated into the PCM-KD user interface. The PCM-KD is equipped with a host communication port (Ethernet IP or Profinet).

Related Content

Gravimetric Feeder is Compact, Easy to Clean

Said to offer precise rate control for free-flowing pellets and granules.

Read MoreFeeders Now Furnished With Portable Touchscreen Controller

New portable controller maintains functionalities of previous controller while introducing significant enhancements.

Read MorePiovanGroup Announces Transition In Leadership In North America

John Erkert ascends to Regional CEO position for North America as industry veteran Kirk Winstead retires.

Read MoreFinding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More