Solid Pin for Cost-Effective Assembly of Two Plastic Components

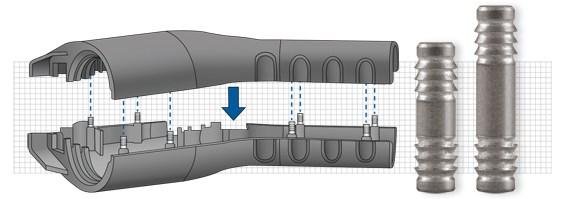

Spirol’s new BP100 Press-N-Lok Pin boasts quicker assembly time and lower assembly equipment costs compared to screws and adhesives.

A solid pin for permanently retaining two plastic components to each other has been newly added to the Solid Pin product line of Spirol International, Danielson, Conn., a leading manufacturer of a diverse line of engineered components for fastening, joining and assembly. One major advantage of the new Series BP100 Press-N-Lok Pin is that assembly time is quicker and it requires lower assembly equipment costs as compared to screws and adhesives.

The Press-N-Lok Pin has opposing raised barbs on each end that are angled backwards opposite the direction of insertion. As the pin is being inserted, the plastic backfills into the area around the barbs resulting in maximum resistance to axial force reportedly providing a secure, tamper resistant assembly. Manufactured from lightweight, lead free, corrosion resistant aluminum, the Press-N-Lok Pin is installed in two steps:

▪ Step 1: Press the pin into one-half of the plastic housing.

▪ Step 2: Align the other half of the housing with the exposed end of the pin and press into place.

Spirol offers complimentary applications engineering support. Spirol engineers will review a company’s application requirements and work with their design team to recommend the best solution at the lowest total assembly cost.

Related Content

-

End-to-End Quality Management For Aseptic PET Beverage Bottling

Sidel introduces Qual-IS comprehensive quality system to merge all QC activities in PET aseptic beverage bottling, from the preform blowing to laboratory management.

-

Polyfuze Graphics Corp. Partners With RFID Specialists

To help customers navigate the complexities of RFID technology, Polyfuze has partnered with such companies as HID Global.

-

Transforming Laser Marking Operations With Collaborative Robotic Automation

FOBA partners with Flexxbotics and Universal Robots.