Tooling: New Flat Die Nozzle and Cloud-Powered Mold Monitoring

Haidlmair Group will launch two new companies and two new products at K 2019, including a new iteration of its flat die unit (FDU) and a mold monitoring technology.

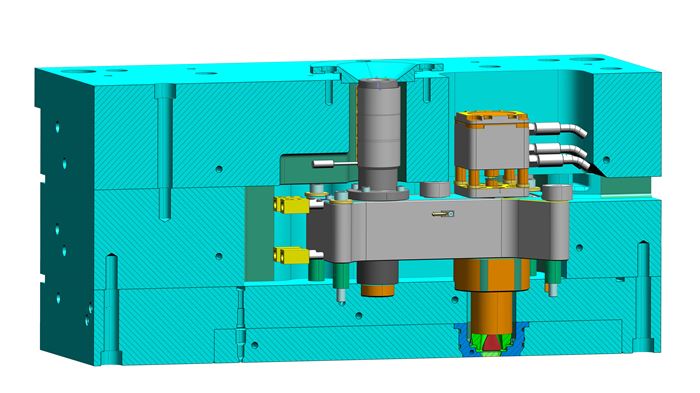

Haidlmair Group has created FDU Hotrunner GmbH (Frankenthal, Germany) to distribute and develop the company’s FDU (flat die unit), which originally launched at K 2016. At K 2019, FDU Hotrunner will introduce a new nozzle, the FDU SLS (Slot Lock System). Building off the company’s blade closure shut-off technology, the FDU SLS features a guide system with anti-twist protection for the blade that doesn’t divide the melt flow.

Through this, cross sections up to 175 mm2 exit area and large shot volumes can be injected without stress or shear at high speed. This also means lower injection pressures can be used compared to the conventional FDU, without jetting and consistent fill and hold. The company says the first iteration of the FDU achieved cycle time reductions up to 25% with more possible from the SLS version.

At the show, a mold utilizing the new nozzle will be running on a KraussMaffei injection molding machine making a container. Additional Haidlmair molds will be in action at the booths of Erema, Woojin, Engel and Sumitomo Demag.

The second new company—Digital Moulds GmbH—will promote the mold monitoring system launched at K 2016. This platform monitors and records various parameters, including cycle time, temperature, flow rate, cavity pressure and more. New at K 2019 will be a technology that the company says centrally documents and visualizes the entire life cycle of a tool. Mold Lifecycle management is a cloud-based software that gathers all a mold’s relevant information, documents, drawings and parameters in a database. Access can be shared among relevant stakeholders.

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.