Twin-Screw Feeder Ideal for Hard-to-Handle Materials

Twin-screw gravimetric feeder features a horizontal agitator so that the two screws are always filled with material.

For more difficult-to-handle materials, Coperion K-Tron has expanded its line of ProRate PLUS feeders with the PLUS-MT. This twin-screw gravimetric feeder features a horizontal agitator so that the two screws are always filled with material. The steep design of the hopper walls allows poorly flowing bulk solids to be fed reliably without an additional vertical agitator. Should material bridging or ratholes still occur, one or more of Coperion K-Tron’s ProFlow bulk-solids activators can be mounted on the hopper to promote material flow.

These ProFlow bulk-solid activators consists of an electromagnetic vibrating device, which activates the feed hopper to keep bulk materials moving. The device operates at an optimized frequency and amplitude to ensure minimal energy consumption and maximum product flow. Thanks to its smart electronic control, ProFlow only uses 3.6w of electricity. Tests with a wide range of bulk materials have shown that ProFlow is an ideal solution for a variety of bulk materials. ProFlow has no wear parts and since it is mounted outside of the product contact area, there is no additional cleaning effort needed.

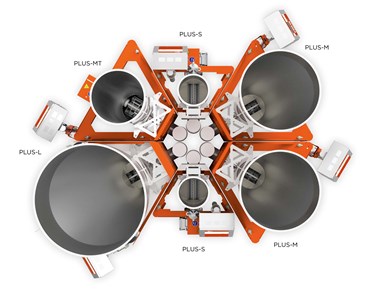

The ProRate PLUS feeder line features a space-saving trapezoidal shape, which allows up to six feeders to be easily grouped around an extruder inlet within a 5 ft radius. The four feeder models (PLUS-S, PLUS-M, PLUS-L and PLUS-MT) cover a wide range of throughputs. The ProRate PLUS feeders are capable of handling feed rates from 0.12 up to 400 ft3/hr, depending on the material. Theoretically, a feeding system with six ProRate PLUS-L feeders can feed up to 1017 ft3/hr on a footprint of 75 ft2.

Photo: Coperion K-Tron

All ProRate PLUS feeders are equipped with P-SFT load cells, featuring reliable Smart Force Transducer single wire weighing technology. Each feeder also comes equipped with its own pre-wired and pre-tested ProRate PLUS PCM control module. The PCM is mounted to the feeder stand, with adjustable height positioning. Most feeders only need a basic motor control unit (PCM-MD) while one feeder per group of eight is equipped with an advanced version featuring an integrated user interface and line control functionality (PCM-KD).

Related Content

-

Safety, Recycling, and Compounding Trends Bring New Opportunity to 70-Year-Old Company

NPE2024: Vac-U-Max presents pneumatic conveying solutions for powdered materials.

-

How to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

-

Conair Names New Head of Customer Care

Jared Helfrich to direct the efforts of the machine builder’s growing customer care group, combining its existing parts and service and repair organization with a new range of fast-growing customer services.