10 Ways 3D Printing Is Advancing Plastics Manufacturing

3D printing expands possibilities for plastic parts, short-run molds and production mold tooling. Here are just 10 of the ways 3D printing is advancing:

There are certain applications 3D printing cannot touch, and might never be able to. For a production run of hundreds of thousands of parts, for example, the option to 3D print plastic components cannot come close to competing with the speed and efficiency of an established process such as injection molding. However, in many other applications and in many different uses, 3D printing is both improving plastics manufacturing and expanding the options for plastic parts. Here are just 10 of the ways 3D printing is advancing:

1. Faster throughput

At certain scales, 3D printing is indeed an option for production, and the scale is increasing. Some 3D printers engineered for production today generate parts at rates an order of magnitude faster than what has previously been accepted. 3D Systems, for example, says its Figure 4 production 3D printing system increases speed by a factor of 15 over previous industrial 3D printers, reducing the unit cost of a 3D printed part by 20 percent, thanks in part to the cycle time reduction.

2. Bigger parts

A very large polymer 3D printer such as the Cincinnati Incorporated BAAM machine might offer a build volume of 180 cubic meters. This is huge, and machine models such as this capture a lot of attention. But just as notable is the range of machine models now available at sizes that are much smaller, yet still large. Various machine builders have introduced cost-effective industrial 3D printers making parts the size of a large molded component. A representative example, the 3DMonstr Super-Rex 3D printer, offers a build volume of 3 cubic meters.

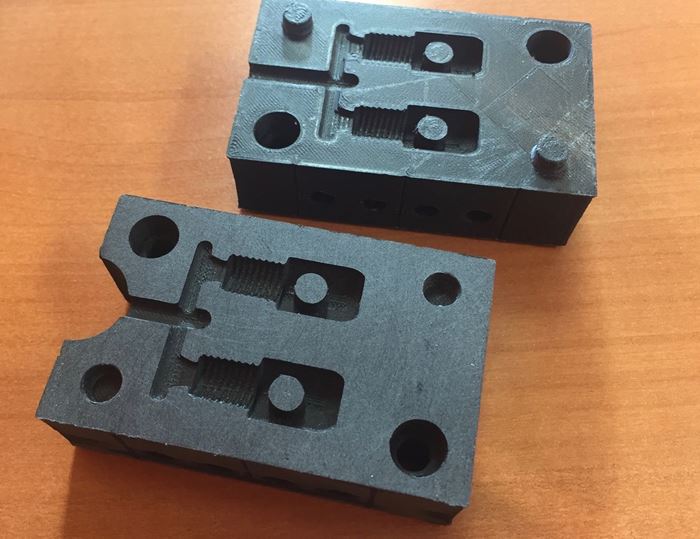

3. New options for short-term molds

3D printing provides a short-lead-time option for directly making a few parts, but it also provides a short-lead-time option for making an injection mold. The right choice of polymer can reliably produce mold tooling for low to medium quantities. Wyoming-based Avante Technology 3D prints injection molds from carbon-fiber-reinforced polymer that have consistently lasted beyond 100 cycles, and the company says could last to 500 cycles.

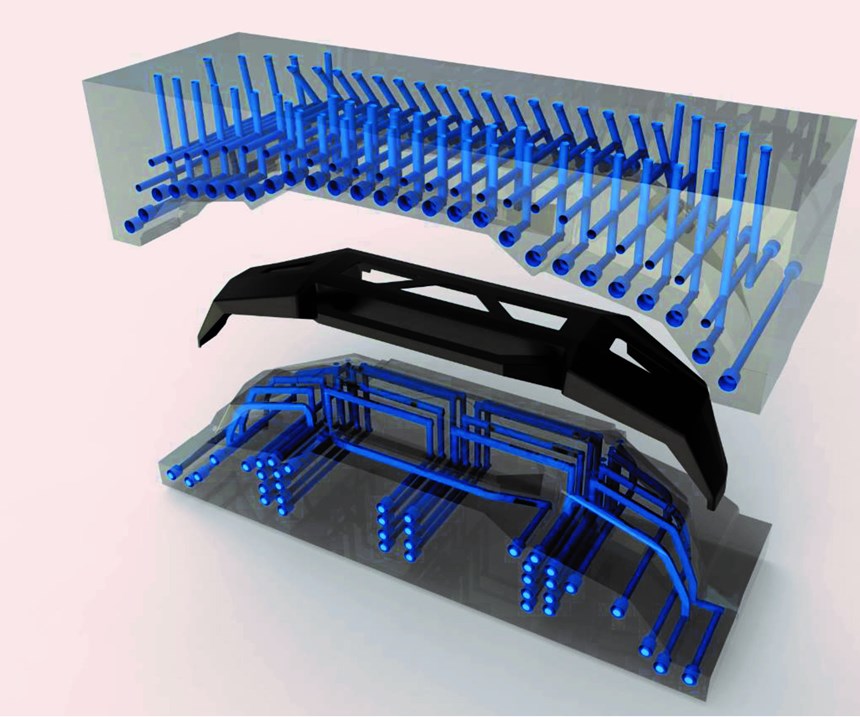

4. More efficient production molds

Meanwhile, 3D printing in steel can make improved mold tooling for high-volume production. With printed-in conformal cooling channels replacing straight drilled holes, the mold’s cooling is more effective, likely improving molded part quality and reducing cycle time. Mold supplier Conformal Cooling Solutions uses robotic deposition technology to 3D print large injection molds with conformal channels.

5. Customization for consumer products

Medical and dental products are now routinely tailored to the individual via 3D printing, so how far are we from consumer products following suit? The work of various footwear providers suggests shoes will soon be widely available that optimally fit the wearer’s feet. Footprint 3D is an example of a company advancing this idea; the firm uses 3D scans of an individual’s feet to 3D print shoes with custom midsoles that use lattices for precise support and cushioning.

6. New manufacturing business models

Can a manufacturing plant locate in the heart of a city? Manufacturers today tend to locate in suburban industrial parks with easy access to major highways. But because of its reliance on 3D printing, Voodoo Manufacturing is able to locate in Brooklyn. The company uses 160 desktop printers working simultaneously to achieve a part production rate that makes the company cost-competitive with injection molding—and faster in delivery—for quantities up to 10,000 pieces.

7. Plastic replacing metal

In many cases, metal is the material of choice for a given part only because it offers the easiest way to get a rugged functional component in a low quantity. Machining the part from aluminum is a practical option. But with 3D printing now able to efficiently deliver polymer parts in low quantities, metal will not be the material of choice so frequently. Carbon-fiber-filled 3D-printed polymer can replace even a hard or strong metal.

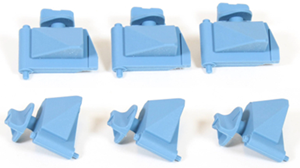

8. More efficient toolmaking

3D printing thrives on one-off parts, and perhaps the most common type of one-off part in any manufacturing facility is its own internal tooling. That is, not just mold tooling but jigs, fixtures and all manner of industrial tools. Much of this tooling can be made from polymer instead of metal components, and when it is made on a 3D printer, it need not consume production capacity or even take up much of the production personnel’s time. With 3D printing, Volkswagen Autoeuropa reduced its tool development time by 95 percent while improving tools’ ergonomics and simplifying tool repair and modification.

9. Prototyping without impeding production

And just as making tooling need not cut into production, making prototypes can be kept isolated from production resources as well. Desktop polymer printers often can be effective not just for look-and-feel prototypes but for functional prototypes as well. Stanley Black & Decker recently introduced a simple 3D desktop printer with a 200 mm square build area. With a resource such as this, the engineer might be able to make a prototype at his or her desk without enlisting the attention of manufacturing staff.

10. Manufacturing moving in-house

As companies adopt industrial 3D printers to accelerate product development by prototyping in-house, it becomes only a short leap to manufacturing production parts in-house as well. Arizona Home Floors, a developer of tools for installing and removing flooring, never intended to become a manufacturer. It had previously outsourced manufacturing. But for a new chipping hammer it recently developed, making some of the components on the same 3D printer that had prototyped the parts proved to be the most efficient approach. As more companies choose this route, 3D printing is expanding not only the application of plastics, but also who is doing plastics manufacturing.

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreGetting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

Read MoreBusiness Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

Read MoreAdditive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

Read MoreRead Next

Video: 3D Printing at Local Motors

3D printing plays multiple roles at the company’s Knoxville microfactory, from prototyping to the production of parts for autonomous vehicles.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More