21 Tips to Slash Energy Costs in Molding

This checklist can provide injection molders a good starting point on the path to reduced energy consumption and can generate some money savings on that journey.

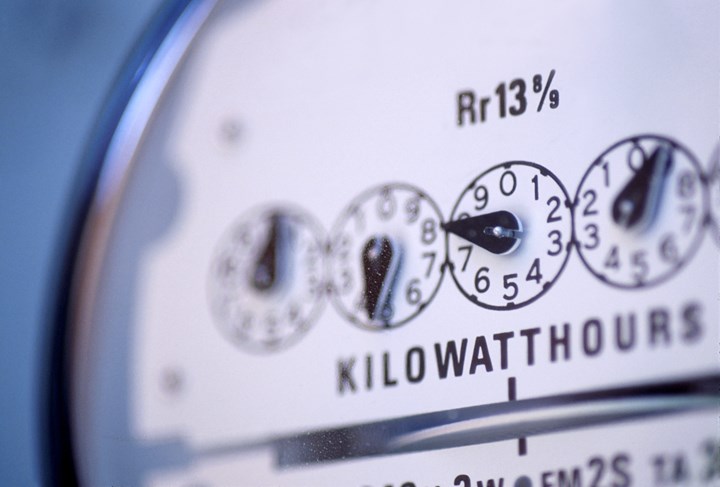

Significant energy savings are available to most molding shops. Time and money spent on reducing power requirements will lower those large utility bills facing you every month. How much could be saved if a shop reduced energy consumption by just 5% or 10%? Thousands of dollars.

Mold cooling: If you want a leg up on your competition, this is it. Most shops do not pay appropriate attention to this issue, and there are big savings to be had here.

There are only two ways to reduce energy costs: lower the amount of power you use or pay less for it. With tightening energy supplies and escalating costs, there is no better time for an initial shop-wide energy audit, or redoing one. What percentage of your utility bill goes toward running injection molding machines and the auxiliary equipment to supports them? My guess would be around 90%.

A Money-Making To-Do List

1. First, find out what your employees would like as a reward for greater efficiency. Money is, of course, always an option; but there might be some other incentives that would motivate them to participate or speak up regarding efficiency. From donating to charities they like, to helping out at a local school, find their best motivator. Push to get as many employees on board for this energy-reduction program as possible, targeting both the office and the shop floor. Ask for energy-saving ideas and publicly acknowledge and reward those who participate.

2. Prominently display a bar chart of your power bills by month, and then explain that if those bills can be reduced, you will reward the employees. Again, the reward doesn’t have to be monetary. Shirts, caps, gift certificates, free lunch day, free coffee or other perks can work as well. If you want greater involvement, let the workers decide on the reward.

3. To reduce electricity usage spikes, do not turn on all your machines and equipment at the same time. Bring machines on in stages or start them at night, early morning or whenever power rates are lowest. Most shops pay for the largest demand (spike) during a 30-day period. Can you negotiate with your power company to change that arrangement? Also when is the best time to turn on a machine? Often power rates during the late evening or early morning are cheaper. Meet with your power company and discuss when rates are lower and how you might cut consumption. Utilities often have programs in place to promote energy conservation. If you do get a lower rate during specific hours, shift heavy grinding or any other power-hungry jobs to those times.

4. Ask your power supplier if it gives credits or rebates for using less energy. Many states have programs to provide assistance; have you asked for help? Obviously, many companies cannot simply build new plants, so the only way they can meet demand is to find ways to reduce energy use.

5. Try to find a recycler or a use for your scrap plastic. Do not throw any plastic into dumpsters; sell it if possible. Here again, ask employees for ideas about how to use scrap material. They may come up with something to make … a toy, ball, disk, water bottle. I bet you have an old mold or two taking up space that could be repurposed to give scrap a second life.

6. When you buy a machine, ask about energy-reducing options, as there are newer motors that provide significant energy savings. Also, you can retrofit older machines with energy-saving servomotor pumps.

7. Match the size of the shot to the press. Using large machines for small parts wastes energy and provides for poor process control.

8. Do not leave machines or hot-runner temperature controllers on if the mold and machine are not in use. This will also help reduce resin degradation by eliminating instances where material sits in a hot barrel.

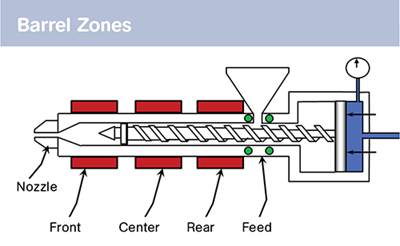

9. Maintain screws and barrels within specifications. Most of the energy to run a machine is consumed during screw rotation or plasticating. Worn screws increase the amount of time required to prepare the melt.

10. Separate the first stage from the second stage in processing, and do not keep either stage on longer than necessary.

11. Do gate-seal experiments to make sure you are not running second-stage or hold pressure longer than what the part requires. Also note that not all parts should be run with gate freeze.

12. Stop thermolators (TCUs) and other auxiliary equipment if the machine is idle.

13. Get the rust, scum etc. out of your cooling lines. Yes this cleaning costs money, but cooling accounts for around 90% of your cycle time, and you can get the best cooling with clean channels. Also, consider whether the part could be ejected hotter and still hold tolerances. Recent studies about how much heat has to be removed show surprising results. Trial one or two machines for cleaning and/or faster cycles with warmer parts and see what the payback is.

14. Check for air leaks. “Not a big problem,” you say; well, think again. A 1/8-in. diam. air leak over the course of a year running at 90 psi pressure generates an estimated cost of more than $4500.

15. Check that the dump valve is not leaking on mold-temperature controllers. If this valve leaks it is costing you money.

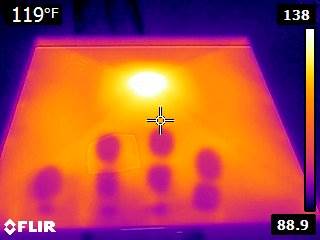

16. Cooling takes up the vast majority of your cycle, so make sure you have turbulent flow and minimum temperature rise (less than 4°F or 2°C) going through the channels of the mold. Filter your water and make sure all supply and mold-cooling lines are clean for the best heat transfer. If you want a leg up on your competition this is it. Most shops do not pay appropriate attention to this issue, and there are big savings to be had here.

17. Watch use of granulators, preferably running them at night and not allowing them to idle. There must also be a mechanism to ensure workers do not start the granulator with scrap already inside.

18. Vent the hot humid exhaust created when regenerating the desiccant in desiccant dryers when the air conditioning is on. We do not vent our home clothes dryers into our air-conditioned houses. Check out the newer drying technologies, including infrared, vacuum and more. Beyond that, make sure all hose connections on your existing dryers are tight and that there are no holes leaking hot, dry air.

19. While barrel blankets do save energy they are not recommended because they can impact temperature control on the barrel, resulting in hot spots that lead to resin degradation. (One exception is if the machine is near a garage door that is constantly being opened and closed.) You can and should insulate the individual heater bands.

20. Look for ways to recover heat from your cooling water etc.

21. Get a power meter and start checking equipment for energy usage. What is normal for this size machine, and perhaps more importantly, what is abnormal?

Time and money can be saved by taking a closer look at your injection molding plant’s power consumption. (Photo: Thinkstock)

About the Author

John Bozzelli

John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. E-mail john@scientificmolding.com or visit scientificmolding.com.

Related Content

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MorePurpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreRead Next

What’s Controlling Your Cycle Time? Part 1

Follow these guidelines to maximize your profits.

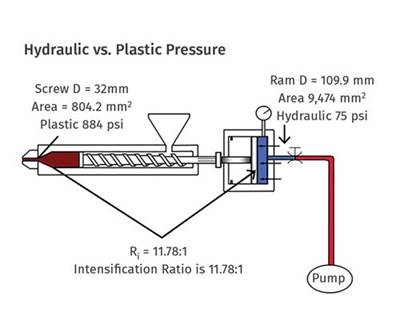

Read MoreUnderstanding Intensification Ratio

A first step in taking the “art” out of molding.

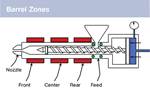

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read More

.jpg;width=70;height=70;mode=crop)