A new automation supplier has targeted the traditional barriers to robotics—capital investment, programming time, job-to-job inflexibility—and offers manufacturers a different model. Jordan Kretchmer, cofounder and CEO of Rapid Robotics in San Francisco (rapidrobotics.com), comes to manufacturing from the world of enterprise cloud software after selling his first business venture to Adobe. As he looked to start a new company, Kretchmer targeted industries applying business models based primarily on capital expenditures—an antiquated philosophy in his view. “I was looking for opportunities where there was desperately needed innovation to solve a big problem in the space,” Kretchmer says. “Where a new kind of business model that wasn’t based on capex would have a huge impact.”

Kretchmer and his partners found that opportunity in robotics for manufacturing, specifically automating machine-tending jobs that require the low-skilled/high-turnover workers many fabricators struggle mightily to find and keep. “Every manufacturer that we speak to has a 10-person minimum open head count for operators, and that’s debilitating,” Kretchmer says. “Their businesses are struggling; they cannot grow; they cannot scale; they’re turning down jobs because they can’t hire enough people to do this work, and that is what we’re here to solve.”

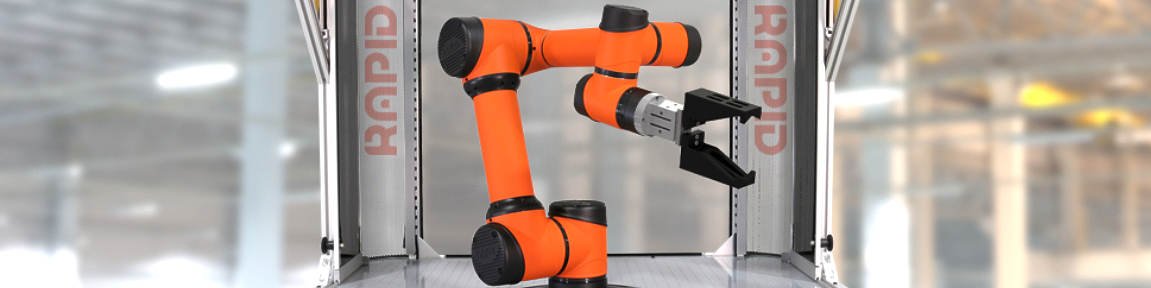

Rapid Robotics’ solution: the Rapid Machine Operator (RMO)—a pre-programmed, six-axis collaborative robot (cobot) arm outfitted with vision and other sensors and controlled via an iPad. Rapid’s customers rent these “ready-to-work robotic machine operators” for $25,000/yr. For that cost, the customer receives a cobot arm with a 1-m reach and 10-kg payload capacity made by Aubo Robotics of Knoxville, Tenn. (aubo-robotics.com) that comes programmed to run a predetermined task.

The Rapid Machine Operator (RMO) is a pre-programmed, six-axis cobot arm with a 1-m reach and 10-kg payload.

End-of-arm-tooling is designed by Rapid and 3D printed, either by Rapid for $50, or if the customer has a printer, Rapid will send the design file. “Our customers are not buying the arms,” Kretchmer says, “they do not have to take ownership of them, so they do not have assets sitting on their books. We take on that burden.” Here, the robot and the EOAT are viewed as commodities.

“We look at the equipment as throwaway,” Kretchmer says. “It’s commonplace now and as a result of that, we’re able to focus all of our energy on the intelligence and not the hardware. We approached EOAT in the same way we approached the arms. They are commodities, and you should not have to go and buy a $10,000 gripper to pick up a certain part, and you’re then going to have to go and buy another gripper for another kind of part later.”

Rapid’s fixturing components are also 3D printed. Customers send Rapid a CAD file of the parts to be handled, and from that, Rapid’s mechanical engineers create a fixture and gripper strategy.

“This means the grippers and fixtures are throwaway,” Kretchmer says. “So if you’re running a task for six months, and you’re trying to maximize your return on investment, buying a $5000 or $10,000 end effector is going to cut into that, so we’ve made them as inexpensive as possible.”

New Customer Process

Rapid Robotics kicks off a potential partnership with a new customer in an introductory call featuring some standard questions: How many operators are in your facility? How many secondary machine operations do you run per shift? How many secondary machines are on your floor? What kinds of machine types do you have—pad printing, ultrasonic welding, machine staking, stamping, CNC machining, etc.?

Everything is considered from a “task” basis, according to Kretchmer, with the next step being an in-person site walk. That visit determines a pilot project, for which Rapid offers a 14-day free trial deployment. For this, Rapid sets up automation of a simple task like pad printing to give the customer a feel for what’s possible. Kretchmer says the fastest the company has ever gone from an initial conversation to having an RMO working on the floor producing parts was a week and a half, with the average amount of time from first contact to deployment being three weeks.

Meet Melvin, Kim and Nancy

Rapid Robotics’ unusual automation pitch fell on receptive ears at Westec Plastics Corp. in Livermore, Calif. “In 2019, we set a goal for ourselves to look and see what programs we could automate,” says Tammy Barras, Westec Plastics president. Like many custom injection molders, Barras says the common barrier to automation at her company is their lack of “evergreen” projects that run constantly and are suited to a dedicated robot. “It was hard to want to spend the money to automate something if you were only going to be running it a week, a month, or however often that particular program ran,” Barras says.

Westec’s first RMO, dubbed Melvin, performs hot-stamping tasks for the custom molder.

“Rapid felt like a really good fit for us because they talked about how flexible they could be,” Barras explains. “They could move the RMO from one project to the next—it doesn’t have to stay in the same place—so even if you only ran it one week a month on project A, you could run it on project B the next week.”

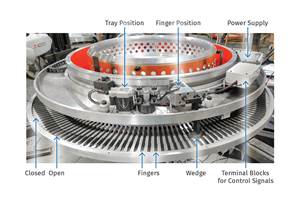

When Plastics Technology spoke with Westec the company had two RMOs in operation—“Melvin” on pad printing and “Kim” on gate trimming/autobagger feeding—with a third, “Nancy,” being installed for weighing and assembly/labeling. Naming the robots is pretty common, according to Kretchmer, if for no other reason than it clarifies which workers—mechanical or human—are tackling which tasks on plant-floor job boards. “Our customers are putting the RMOs on their staffing boards,” Kretchmer says. “So when you walk into one of their facilities, the robots are listed on the board along with all the human operators, including their tasks, output expectations, everything.”

Melvin was Westec’s first foray into RMOs and has been performing full-time hot-stamping duties. Melvin picks up parts from the conveyor to hot stamp them before they’re assembled by an operator running the machine next to “him.” After success with Melvin, Westec added Kim for gate trimming of a medical part that was going from a single-cavity to a four-cavity tool. “We were looking for some kind of automation for that because it was fairly high volume,” Barras says. After trimming gates, Kim drops the parts into an auto sealer that bags the individual parts. Nancy will be working inline with two human operators, taking a completed and boxed assembly and weighing it to make sure all the components are present. If the weight is right, Nancy will label the box and insert it into the final pack-out container.

The knee-jerk reaction to automation, especially in the broader public, is to frame the situation as a machine replacing a person. Anthropomorphizing the robot with a name may even add to that impression. Barras counters this, saying the narrative that “robots are taking peoples’ jobs” is simply not true. “We never have enough operators,” Barras says. “No person has been displaced; we have not terminated anybody because the robot replaced them. It has just enabled our people to do more difficult jobs that a robot can’t do. It has enabled us to get more product out with the same number of people.”

Flexibility to Grow

Westec currently has 23 injection molding machines, having brought in five new presses in 2020, including three two-shot machines to support its growing medical business, which includes cleanroom molding and assembly and some COVID-related contracts. To accommodate the new machines and more secondary operations, the company added 9200 ft2 of warehouse space. As it looks to grow further, finding people will not be a constraint, with Rapid able to redeploy an existing RMO at the company or bring in a new one.

“Rapid does all the designing,” Barras says. “So if I’ve got a new program and I want Melvin to be able to work on it, they’ll figure out how to do it, and they’ll design all the parts and all the EOAT, and they’ll print it all and there’s no additional cost for us.”

Kretchmer says Rapid Robotics has found its niche with companies like Westec. “We are relevant to any manufacturer who does secondary operations. We’re identifying facilities with secondary operations, and then, within that, we’re currently looking at 12 different task types that we do today, but we add a new task type about once a month, based on customer needs.”

Rapid is helping Westec meet current and future needs. “We’re not one of those molders that puts something in the press and runs it 52 weeks a year,” Barras says. “It’s nice to have the flexibility and to be able to move things around when we need to, and not just have that robot sitting there waiting for when we run that particular job again.”

Westec Plastics uses cobot “Kim” for gate trimming and bagging of a medical component.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreRead Next

AUTOMATION—PART 3 Cobots: The New Option for Injection Molders

Take all the versatility of an articulated-arm robot, and add the ability to work safely in proximity to humans without guarding, and you have a new option for freeing workers from repetitive operations.

Read MoreCobot Supplier Launches Leasing Program

Universal Robots has paired with DLL to offer manufacturers a leasing program for its line of cobots and peripheries.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More