A Simple, Repeatable, Realistic Test of Thermoformability

A new test method enables sheet manufacturers and thermoformers to more precisely analyze and quantify the thermoformability of materials.

A new test method enables sheet manufacturers and thermoformers to more precisely analyze and quantify the thermoformability of materials. The Technoform-III thermoformability analyzer was developed by Transmit Technology Group, a plastics testing and consulting firm in Texas. The device is claimed to be a breakthrough because it closely simulates the thermoforming process under controllable conditions and is repeatable and easy to use. From small samples, it collects quantitative information that can be used to predict or compare forming behavior.

Toward consistent sheet

The novel test method fills an important need because of the growing use of thermoforming for large parts and the lack of reliable tests to determine thermoformability, says Amit Dharia, president of Transmit Technology Group. With his new test device, he seeks to elevate thermoforming “from black art to science.”

“The industry has got to have a practical way to get consistent homogeneous sheet,” agrees industry consultant Bill McConnell of McConnell & Co., Fort Worth, Texas. “This would be a boon to the industry, a big help.”

Currently, 75% to 80% of the variability in thermoforming is the result of inconsistent sheet, according to McConnell. He calls this the most pervasive problem faced today by thermoformers. Depending on process conditions, output rates, amount of regrind, and storage conditions, the feedstock may vary in residual thermal stresses from lot to lot and even between sheets in the same lot. This creates a “blind spot” that converters generally overcome by on-line adjustment of the thermoforming process.

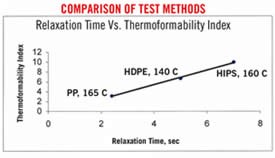

According to Dharia, current formability tests do not accurately reflect the thermoforming process. Among the current methods are the hot tensile/creep, dynamic rheology, melt-tension, and sag tests. In the absence of more useful test methods, thermoformers have had to resort to full-scale thermoforming trials, which require expensive material, tooling, and machine time.3

Mimics actual forming

The Technoform-III analyzer is a miniature thermoforming machine with heating, forming, and cooling functions. It uses a 6 x 6 in. square sheet sample of 20- to 140-mil thickness, preferably die-cut from actual extruded sheet. The sample is clamped between two insulated plates, forming a “tray,” which is placed manually on the loading rail.

The software input menu includes selection of forming method (plug, vacuum, or plug-assisted vacuum), temperature, heating rate, heat-soak time, plug speed, cooling time, maximum plug force, and maximum draw depth. When the test cycle is actuated, the sample tray moves into the oven, where upper and lower infrared heaters heat the sample from both sides. Heater temperatures and distance between heaters and the sample can be adjusted independently. A noncontacting infrared probe continuously measures the sample’s surface temperature. Upon achieving preset surface temperature or temperature and heat-soak time, the tray moves into the forming station within 1 sec. A plunger with a male plug is applied at a programmed speed and a load cell on top of the plug continuously measures the deformation force. When a preset maximum force or deformation distance is achieved, a fan cools the sample for a programmed time. The part is then removed manually from the tray and visually inspected. The test takes less than 30 sec.

Part thickness distribution is measured and recorded manually. The force data are plotted as a function of draw distance or time. The force required to achieve a specified draw depth—or the draw depth achieved with a specified force—is termed the Thermoformability Index (TFI). A higher Index at the desired process temperature indicates better thermoformability. A high Index over a wider range of temperatures indicates better formability with a broader processing window.

The 107-lb tabletop test unit is 30 in. long, 18 in. high, and 12 in. deep. “The fact that it is modeled after a commercial thermoforming machine is the key,” says Donald Hylton, an associate with McConnell & Co. and a research scientist at Clark Atlanta University.

Cost may be an obstacle

Dharia said he will offer two models of test units: one at $18,000 only for pressure forming and another at $27,000 for pressure and vacuum forming. If the machine wins strong adoption, the price could come down, he said. The test unit was unveiled at the SPE Thermoforming Conference in Milwaukee in September.

Hylton notes that the tester’s cost may be a stumbling block to commercial acceptance. “Processors in the thermoforming industry are accustomed to trial and error,” says Hylton. “But no one has determined what that trial and error means in terms of cost. This device could be a major savings.”

Dharia hopes that ASTM in Philadelphia will recognize his test and that the Thermoformability Index will be adopted for the industry.

Related Content

Winners Announced for SPE Thermoforming 2023 Parts Competition

More than 30 entries were considered, including 10 in the Sustainability category.

Read MoreNovel ‘Clamtainer’ Extends Thermoformer's Reach in Packaging

Uniquely secure latching expands applications for Jamestown Plastics’ patented clamshell package design.

Read MoreSheet Extrusion, Thermoforming Tips for PLA/aPHA Blends

Biopolymers like PLA and PHA are able to meet sustainability goals while also delivering the performance attributes needed in rigid food packaging. Here’s what testing has shown.

Read MoreOrigin Materials Unveils CapFormer for Producing PET Caps

Factory acceptance test completed at commercial scale.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More