Absolute Haitian Brings Next Generation of Presses to Orlando

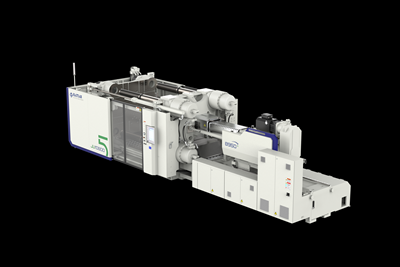

NPE2024: Absolute Haitian says Generation 5 of the servo-hydraulic Haitian and electric Zhafir machines lines emphasize efficiency, performance and intelligence.

In addition to new larger, improved controllers, all the new Generation Five injection molding machines on display in Orlando feature electric screw rotation as standard. Glenn Frohring, one of the owners of Absolute Haitian, the exclusive distributor of Haitian servo-hydraulic and Zhafir electric injection molding machines in the U.S. and Canada, notes the company was able to integrate electric screw rotation through its own captive, in-house solution. The electric screw drive is standard on servo-hydraulic machines up to 120 mm, reducing energy usage by at least 20% while improving process stability.

“It’s really a huge benefit if customers want parallel operations,” Frohring says, with the machines able to complete screw recovery during clamp open /close, for example, via an additional servo drive inverter. As an example, Frohring says that if a customer with a 500-ton machine featuring a 60-ounce shot size wanted to add an electric screw drive and parallel motion, Absolute Haitian would only need to add inverters and shutoff mechanics (including a valve gate or shutoff nozzle) at a cost that’s just 30% of what the customer might have paid in the past for such an upgrade.

On the new 15-inch control, Frohring says it features flexible core screens and instead of the on/off setup with the prior control, the new one has more functionality and flexibility. “Users have the ability to tie everything together, tighten up cycle times and eliminate some time delays from the shift in the controller,” Frohring says. “Instead of sequential functioning, more actions can occur simultaneously.”

In addition, use of OPC UA protocols enables the control to extract data for MRP and plant-monitoring platforms, as well as create time and data stamps for critical parts in accordance with traceability requirements for markets like medical or automotive. “HMI screens show the integration of auxiliary equipment, water, dew point monitors for dryers, etc.,” Frohring says. “Those screens are all standard in the control, so you have the ability to tie in and really have a more complex, more unified manufacturing cell.”

Frohring says the goal is to make its machines ready for Industry 4.0, whether its customers are or not. “The thing about having data collection and OPC UA and Euromap protocols built into the control as standard is that it satisfies the market’s desire for connectivity and Industry 4.0,” Frohring says. “A lot of customers aren’t there yet, but they also don’t want to buy equipment that would be costly to retrofit. It’s a more universal protocol that won’t force customers to buy only certain brands of auxiliaries or force them to accept a customer-built protocol within the IMM. Everything Haitian does will be universally accepted.”

The Generation 5 machines also have a smaller footprint thanks to an optimized frame structure, with the weight of the machines also reduced because of a new platen design. The lower platen weight results in faster movements with a reduction of 20% in dry cycle times.

To introduce Generation 5 to North America, Absolute Haitian has four machines at its booth: Zhafir Zeres 5 electric, Zhafir Venus 5 all-electric, Haitian Mars 5 servo-hydraulic and a Haitian Jupiter 5 servo-hydraulic two-platen. The 214-ton Zhafir Zeres is molding a medical IV filter from ABS using an 8-by-8 cavity stack mold in an 18-sec. cycle. The parts, with weights of 1.5 and 2.2g, are removed by a Haitian Hilectro top-entry robot.

The 101-ton Zhafir Venus 5 all-electric is molding 3.2 g syringe barrels from Tritan copolyester with a 4-cavity tool and an 18-sec. cycle. The 315-ton Haitian Mars 5 servo-hydraulic is molding a consumer storage container in PP from a single cavity in a 50-sec. cycle, with the parts removed by a Haitian Hilectro top-entry robot. Finally, the 731-ton Haitian Jupiter 5 servo-hydraulic two-platen machine is molding a PC/ABS automotive out panel from a 2-cavity mold in a 60-sec. cycle with part removal by a Haitian Hilectro robot.

Related Content

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreRead Next

Next-Generation Servo-Hydraulic and Electric Injection Molding Machines Launch

NPE2024: Absolute Haitian will introduce Generation 5 of the Haitian and Zhafir machines lines, emphasizing efficiency, performance and intelligence.

Read MoreAbsolute Haitian Opens Its First U.S. Machine Assembly Plant

South Carolina operations center to assemble and test larger presses and stock machines for faster delivery.

Read More