Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Additive Fusion Technology combines high-resolution material deposition with compression molding to create composite materials that make the best use of continuous carbon fibers by placing them exactly where they are needed. The technology has been pioneered by Swiss-based supplier 9T Labs, which was founded in 2018.

9T Labs’ process optimizes the layup for a given application, both in terms of product performance and build efficiency. The process begins with a customer supplying a desired geometry and loading requirements. 9T Labs uses its own software, called fibrify, to analyze the model. Using finite element analysis, fibrify determines the areas of stress concentration. The design is optimized both for handling the strength requirements and for manufacturability.

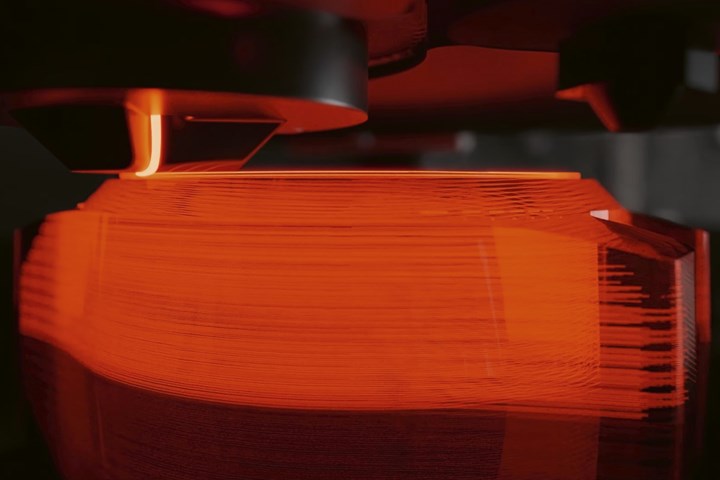

Build design cutaway showing the strategic placement of continuous fibers. Photo Credits: 9T Labs

The Build Module uses the final design to create a preform, with continuous fibers precisely placed exactly where they need to be. Material is deposited through two guides that place fiber-reinforced composite tape next to thermoplastic-only tape. By laying down the material in this intentional manner, the process leads to a product that is strongest just where it needs to be and nowhere else, using the material efficiently and limiting build time. Volumes where the peak load is lower are filled with plastic alone or plastic reinforced with short fibers.

Finally, the part is finished in the Fusion Module, which compression molds the final shape of the part. The printed preforms are flat, but can be reshaped while being consolidated in the Fusion Module, enabling the production of much more complex parts.

Optimizing the Build Path: It’s About the Journey

Recently, 9T Labs added several improvements to its Build Module, increasing part output to 10 times the rate of the previous generation. New actuators, additional sensors and advanced firmware controls are expected to enable greater repeatability and throughput. The new deposition head is modular, facilitating future upgrades, and new bed-leveling and tape-cutting components are expected to extend wear life.

But the process improvements go beyond hardware, as Yannick Willemin, 9T Labs’s director of business development describes. “There is a lot of software optimization to consider, it’s kind of a navigation system to shorten the total movements required to deposit the same amount of material. If you can win a second here, a second there, it adds up to minutes or more,” Willemin says.

9T Labs Red Series Build Module (left) and Fusion Module (right).

After evaluating hundreds of applications, 9T Labs developed an understanding of ways to reduce the paths taken by the Build Module, and also reducing maintenance time by optimizing cutting points. Whenever a cut is made, the build module needs to be stopped, the cutting initiated and then the fiber re-anchored so the lay up can continue. “It is not only the physical optimizations like better hardware and so on, it is optimizing the software code,” Willemin says.

High Durability for Demanding Applications

Materials used by 9T Labs include PEKK and PA12, with other thermoplastics to follow, combined with carbon, glass or basalt fibers. 9T Labs has taken an open approach to materials, enabling customers to choose without being bound to an exclusive supplier.

The technology for producing lightweight, strong and durable parts has found applications in aerospace and in ground mobility. Because the process does involve a metal mold, it is more suited for serial production than a one-off situation. As a replacement for aluminum parts, such as motorcycle rocker arms, the composite parts produced can be 30-40% lighter. As a replacement for traditionally manufactured composites, benefits come in terms of cost and waste reduction because the preform is near-end shape. This contrasts with subtractive machining of composite parts, which may waste half or more of the starting material.

Strength and material efficiency are not the only motivations for using additive fusion. Anisotropic fiber orientation can also provide flexibility in textures, imbuing high-end products with aesthetic differentiation. In 2022, Oris chose the platform for producing the outer casing of 1,000 limited edition watches. Fibers were laid in specific directions to give the product’s surface an ordered pattern, distinguishing it from the familiar rough pattern associated with composites with random fiber orientation. A higher volume watch, using the same technology, was launched in 2023.

9T Labs operates the Build and Fusion modules for its customers at its own facilities, located in Zurich, Switzerland, and Lowell, Massachusetts.

Related Content

Additive Technologies for Injection Mold Tooling Ride Tailwinds

NPE2024: Lowering barriers to additive manufacturing adoption in toolmaking.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreNPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Read More420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More