October 2005 Issue

October 2005

.jpg;maxWidth=600;quality=70)

Features

Featured articles from the October 2005 issue of Plastics Technology

No. 42 - Underwater Pelletizing

When new plastics appeared, suppliers had to prepare them in a form handy for further processing.

Read More

No. 20 - Thermoplastic Elastomers

The invention of materials that process like thermoplastics but imitate the properties and feel of crosslinked rubbers began in 1958-59 with the commercial introduction of thermoplastic polyurethane and styrenic block copolymers (SBCs). The attraction of simpler and faster processing plus the ability to reprocess scrap gained these materials a permanent market niche that has expanded enormously since.

Read More

No. 12 - Parison Programming

The invention of the electronic parison programmer in 1958 helped to make extrusion blow molding a more efficient and productive plastics manufacturing process.

Read More

No. 10 - Desiccant Dryers

Still considered the “gold standard” for drying hygroscopic resins—those that absorb atmospheric moisture—desiccant dryers first emerged in the late 1950s, when Carl Whitlock, founder of Application Engineering Corp. (AEC), developed the first regenerative dryer using silica gel as the desiccant.

Read More

No. 28 - Multi-Material Injection

Injection molding of two or more materials or colors—or the same material in foam/solid or virgin/ regrind combinations—offers a wide range of opportunities to use materials more cost-effectively and/or combine materials for optimum functionality without the added cost of secondary assembly operations.

Read More

No. 22 - Takeout Robots

Automated part takeout was said to originate in Japan in 1967 with Sailor Pen Co., one of the first manufacturers in the region to use injection molding presses.

Read MoreNo. 48 - Film/Sheet Thickness Sensors

Film gauge control was of limited effectiveness before there was a means of online thickness measurement.

Read More

No. 18 - Carbon Fiber

The pioneering efforts of Union Carbide scientists Roger Bacon and Leonard Singer led to the development of carbon fiber in 1963.

Read More

No. 17 - Melt Indexers

The melt indexer originated with ICI in England as an adjunct to its work on developing LDPE in the 1940s.

Read MoreNo. 8 - Ultrasonic Welding

In the early 1960s, there were a limited number of techniques to join plastics components.

Read More

No. 13 - Structural Foam

Until the mid-1960s, thermoplastic molding processes had no presence in large, flat, structural parts such as pallets or furniture that were then dominated by metal, wood, and thermoset fiberglass composites.

Read More

No. 31 - Hals UV Stabilizers

Hindered amine light stabilizers (HALS) can be considered the most important development in light stabilization for many polymers.

Read More

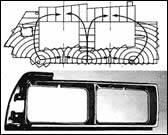

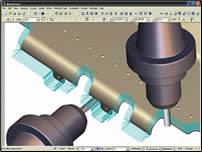

No. 19 - Injection Molding Simulation

Until the late 1970s, the two tools molders employed to optimize mold filling were trial and error.

Read MoreNo. 32 - All-Electric Injection Presses

One of the most significant and highly publicized trends in injection molding of the last two decades has been toward all-servo-driven electric injection presses.

Read More

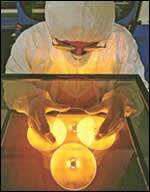

No. 4 - Polycarbonate

The modern era of engineering thermoplastics was launched in 1953 when Dr.

Read More

No. 36 - Cavity-Pressure Sensing

The collection of real-time data from inside the mold first occurred through cavity-pressure sensing and marks the origins of closed-loop injection machine control.

Read MoreNo. 49 - Density Separation Of Mixed Waste

Plastics recycling is a tough business, and it would not have advanced this far without a cost-effective, automated way to separate mixed waste into relatively pure fractions.

Read MoreNo. 45 - Auto Gauge Control For Blown Film

Automatic gauge control for blown film is relatively recent.

Read More

No. 7 - Sheet Molding Compound

Bayer AG in Germany was the first to develop a process to produce thermoset polyester sheet molding compound (SMC) during the early 1960s, while Owens Corning Fiberglas was instrumental in bringing the process to the U.S.

Read More

No. 37 - Spray-Up Composites

What used to be known as FRP (fiber-reinforced plastic) spray-up came on the scene in the 1950s as a more efficient open-mold laminating system that required less time and labor than hand lay-up for making large composite parts.

Read MoreNo. 46 - Auto Gauge Control For Flat Dies

Automatic thickness control of slot dies for cast film and sheet began in the 1960s.

Read MoreNo. 39 - PUR Thermal Insulation

Polyurethane rigid foam insulation for use in both the refrigeration and building/construction markets was in its infancy in 1955.

Read More

Hybrid Prototyping Process Combines Casting and Machining

A new rapid-prototyping technique combines casting with CNC milling in a novel way to create prototype parts fas ter than conventional rapid prototyping approaches—and it all happens in one machine.

Read More

No. 23 - Pressure Forming

Thermoforming was re shaped when com panies like OMV Group in Italy and Brown Machine in Beaverton, Mich., developed positive-air-pressure thermoforming systems that gave parts improved detail and structural integrity along with an injection molded appearance.

Read MoreNo. 24 - Rotary Thermoforming

The development of the rotary machine in the mid-1950s significantly increased production capabilities for U.S. thermoformers.

Read MoreNo. 30 - Hindered Phenolic Antioxidants

Today we take it for granted that polymers can withstand high-speed processing at elevated temperatures and shear rates, and also can take exposure to heat on the job for extended periods without discoloring or embrittlement.

Read More

No. 9 - Stretch-Blow Molding

Biaxial orientation makes plastic bottles clearer, stronger, lighter, and less permeable to moisture and gases.

Read More

No. 15 - Accumulatorhead Blow Molding

evelopment of the first accumulator-head extrusion blow molder by Germany’s Kautex (later Krupp Kautex and then SIG Kautex) in 1963 enabled production of large industrial parts and storage containers with improved wall consistency, strength, and surface finish.

Read MoreNo. 33 - Rotational Molding

Rotomolding is the simplest method of forming a closed, hollow part and the only cost-effective way to form very large hollow parts such as tanks holding thousands of gallons.

Read More

No. 40 - RIM

Polyurethane reaction injection molding (RIM) technology, developed by Bayer AG in the late 1960s, has evolved into a range of rigid (“structural foam”) and elastomeric forms, as well as reinforced (RRIM) and structural (SRIM) composites.

Read MoreNo. 41 - Foam Extrusion

Foam extrusion is a rare instance where the U.S. led the rest of the world in technology by at least a decade.

Read More

No. 5 - Twin-Screw Extrusion

Twin-screw technology topped the experts’ lists as the most significant extrusion development of the past 50 years.

Read More

No. 21 - Hot runners

Hot runners revolutionized the molding process by making part cooling the chief element dictating cycle time and not the sprue.

Read More

No. 14 - Barrier Screws

Barrier screws were invented in 1959 as a way to increase throughput of single-screw extruders and to improve melt quality.

Read MoreNo. 11 - ABS Resins

The addition of butadiene rubber as a third monomer to styrene-acrylonitrile resulted in development of a new range of widely used thermoplastics called ABS.

Read More

No. 38 - Injection Blow Molding

While Plax Corp. and Owens-Illinois Glass Co. made significant contributions to the early development of injection blow molding, the process wasn’t of great commercial significance until the mid-1950s, when Wheaton Plastics Co. launched its first proprietary machine for high-volume production.

Read MoreNo. 50 - Computerized Color Matching

Even 40 years ago, color matching depended on the trained eye and memory of an experienced technician.

Read More

To Catch Trouble Early, Put Your Dryers on the Net

In the past, troubleshooting your resin dryer was a fairly straightforward procedure.

Read More

No. 34 - Gas-Assist Molding

An estimated 15% to 20% of U.S. injection molders use gas assist to core out thick sections, reduce sinks and warpage, and mold larger parts at lower pressures.

Read More

No. 3 - HDPE

The invention of the low-pressure process to make HDPE took place in both the U.S. and Europe at nearly the same time and centered around the development of types of catalysts that promoted ethylene polymerization at milder temperatures and pressures than were (and still are) used for LDPE.The first of these new catalysts was discovered in 1951 by Robert Banks and John Hogan at Phillips Petroleum (who were also pioneers in PP polymerization). In 1953, Prof.

Read MoreNo. 47 - Biaxial Film Orientation

Biaxial film orientation greatly improves film’s tensile strength, flexibility, and toughness.

Read More

A Simple, Repeatable, Realistic Test of Thermoformability

A new test method enables sheet manufacturers and thermoformers to more precisely analyze and quantify the thermoformability of materials.

Read More

No. 16 - Super-High-Heat Thermoplastics

The period from the mid-1960s to the early 1980s saw the emergence of a sub-group of engineering thermoplastics that can be called “super-high-heat” plastics.

Read More

No. 6 - LLDPE

The development of linear low-density polyethylene—originally referred to as “low-pressure” LDPE—was an offshoot of the invention of HDPE.

Read More

No. 29 - Multi-Layer Blow Molding

Packaging innovator Toyo Seikan in Japan was an early pioneer of coextrusion blow molding.

Read More

No. 26 - PET and PBT

PET was invented in 1941 by ICI in the U.K. and played its first role as a fiber, and its second as film with DuPont’s introduction of Mylar in 1952.

Read More

No. 35 - In-Mold Decorating and Labeling

In-mold decorating (IMD) and in-mold labeling (IML) have become important techniques for both injection and blow molding.

Read More

No. 44 - Spiral Dies For Pipe and Blown Film

Spiral dies were the answer to removing knit lines from spider dies.

Read More50 Ideas That Changed Plastics

Very few readers of this issue can remember, or even imagine, what it was like when an injection molding machine did not have a screw, but only a smooth-bore plunger.

Read MoreNo. 43 - Chemical Blowing Agents

Despite early experiments with sodium bicarbonate—ordinary baking soda—the era of foamed plastics had to await the results of German work on hydrazine-based rocket propellents during World War II.

Read MoreBringing You the News For 50 Years

In high schools they teach the history of the Industrial Revolution—the invention of the steam engine, the Spinning Jenny, water-powered looms, and so forth.

Read More

No. 25 - Halogenated Flame Retardants

The use of flame-retardant additives predates 1955, but applications were largely limited in those days to PVC, polyurethanes, and textiles.

Read More