Injection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

In the last few months, I have seen a number of problems related to barrel capacity. I touched on calculating shot size vs. barrel capacity in the past, but it is time to review the subject and hone in on how much barrel capacity you should utilize.

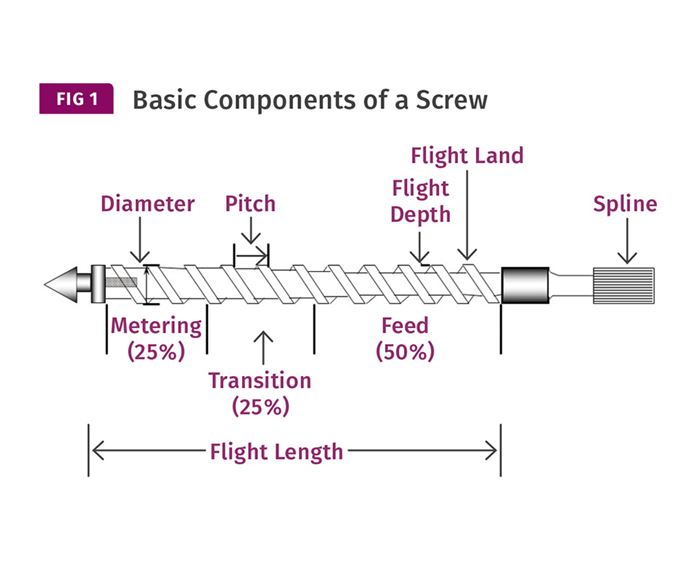

In that column, I stated that your process should take somewhere between 25% and 75% of the barrel or shot capacity. Today, the maximum I recommend is 65%. This may seem a bit odd. Consider a barrel with 230 mm (10 in.) of stroke; why not use it all? What is wrong with using 80% or more (~180 mm or 8 in.)? If you do, you are inviting Murphy to the party, and he will bring along his friends. The reason has to do with how the screw works and the type of resin you are processing—amorphous or semi-crystalline. First, let’s review the basic components and their function for a 20:1 L/D general- purpose (GP) screw. Typically screws have three sections (see Fig. 1):

1. Feed section, which comprises normally 50% of the flight length (10 flights). The purpose of this section is to feed the material to the transition zone, not melt it. It starts the melting process by com- pressing the granules together, which pushes the air that enters the deep flights back out the feedthroat. Also, it transfers some energy (heat) to the granules, prepping them for the transition zone.

Two points to remember here: First, the feed section does

not melt the plastic granules; second, the air that enters with the granules needs to be vented out the feedthroat. The feedthroat must be warm enough to allow the air and volatiles coming off the resin to reach the atmosphere. If it’s too cold you will condense some of these volatiles inside the barrel. But if you have this section of the barrel too hot, you can develop a melt film between the flights and the barrel wall, which traps the air/volatiles and prevents them from venting, which causes splay or bubbles in your parts.

So run the feed throat warm, not cold. You can also ask your most grizzled operator—I call him Old Crusty Senior—how many times he has seen the hopper blown to the ceiling to get an idea of the amount of pressure that can build up. Do not stick your face in that hopper without eye protection.

2. Transition section (also known as the compression section), which normally accounts for 25% of the flight length (five flights). The purpose of this section is to uniformly melt the plastic granules. Your shot has to be uniformly melted in these five flights. In this section, the root diameter expands, tapering to the root diameter of the metering zone. Thus, the flight depth decreases, compressing the plastic up against the barrel wall under significant pressure, which, in combination with the friction of the pellets on the barrel wall, mechanically drives enough energy into the plastic granules to melt them.

Generally 70% to 90% of the energy necessary to melt the plastic comes from this compressing, friction, and screw-rotation combination. The flights of the screw shave the melt film on the barrel wall and push it forward to the final section of the screw.

3. Metering section, which generally makes up 25% of the flight length (five flights). The purpose of the metering section is to pump plastic forward through the check valve, developing the pressure to counteract the back pressure to push the screw backwards to develop the shot size. The metering section is not designed to melt plastic granules. It acts as pump to develop shot size.

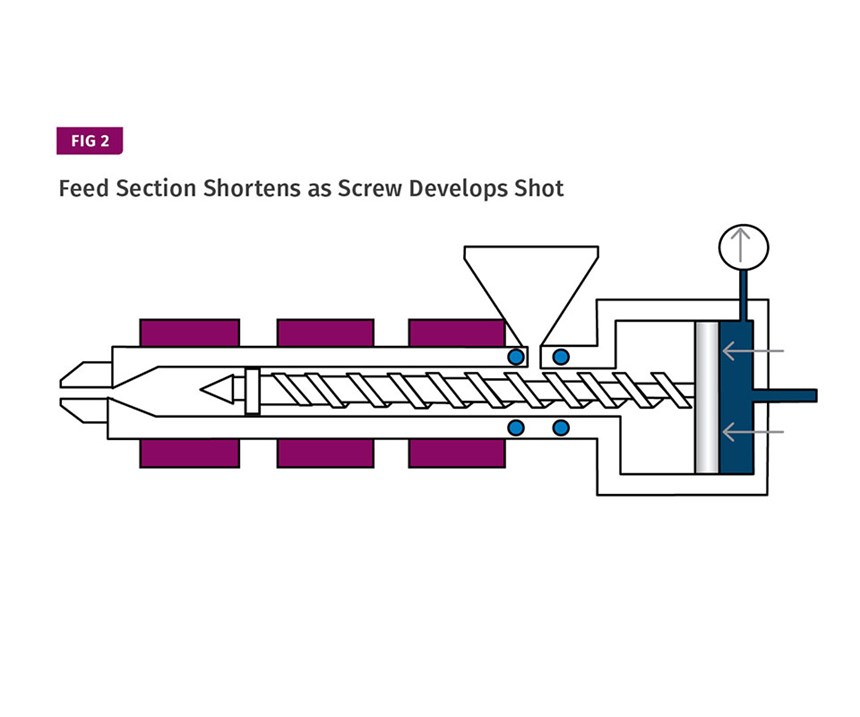

So what’s the big deal about using more than 65% of the barrel capacity? You will have problems with unmelt and melt uniformity that will result in parts that do not look right or function properly. As the screw turns and backs up to make the shot, the feed section of the screw actually becomes shorter, from the point of view of the pellets (see Fig. 2). With large shot sizes, a good portion of the feed section winds up behind the feed throat, and there are only a few flights at most to prepare the granules for the transition or compression zone.

Why is this a problem? The feed section is only meant to feed, not melt the granules. But it also provides some heat transfer, and by effectively shortening the feed section you are not adequately preparing the granules for the transition zone. You may get by if you’re molding amorphous resins, as they melt like butter. They can soften before getting up to their melt temperature, so they are easier for the transition zone to handle. But you are still asking for unmelt.

If you are processing a semi-crystalline resin, you have an entirely different situation. Semi-crystalline resins melt differently, like ice. That is, they stay hard until they reach their melting temperature. In addition, you can bring semi-crystalline resins up to their melting temperature, but they’ll stay solid, just like ice; you need to pump extra energy into them to cause melting.

This is called the latent heat of crystallization. Basically it is an energy barrier, and it can cause severe problems in melting and screw wear. Most semi-crystalline resins not only do not soften but require nearly twice the BTUs (energy) to melt. For example, amorphous ABS takes about 150 BTU/lb to bring it from room temperature to melting. The same amount of polyethylene will take about 350 BTU/lb. Also, factor in the short time your cycle leaves to melt this plastic.

Now you’ll understand why some processors see flights eroded or even completely missing when they pull screws. In addition, you can now also explain why you have unmelt in your parts. Some will argue that the metering zone will finish melting. Not so—it is merely a pump.

ABOUT THE AUTHOR: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. Contact john@scientificmolding.com; scientificmolding.com.

Related Content

The Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreFive Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)